Method for preparing wide-wave reflection film based on ZIFs bidirectional diffusion method

A two-way diffusion, thin film technology, applied in instruments, optical components, optics, etc., can solve the problems of difficulty in adjusting the wavelength and narrow wavelength, and achieve the effect of simple system, simple preparation process, and easy access to experimental materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

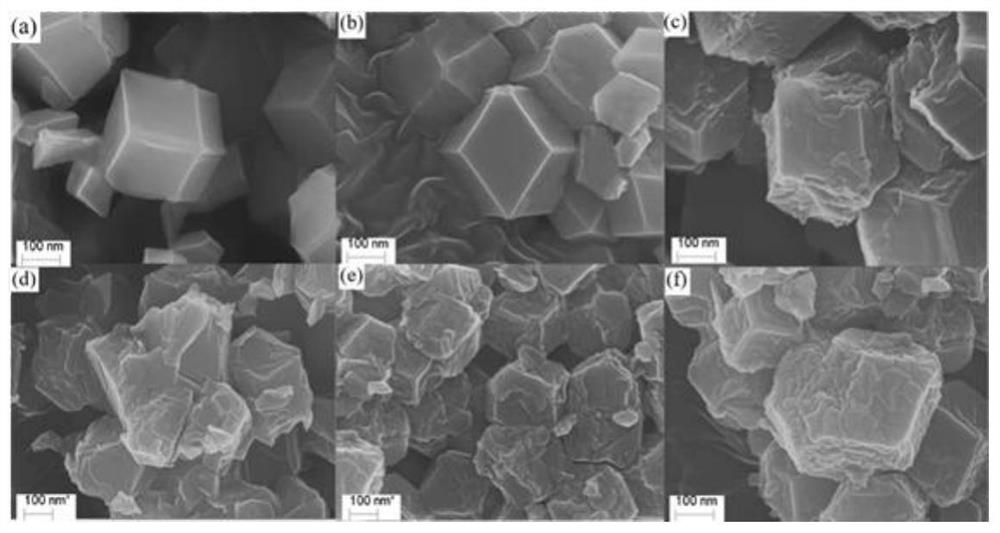

[0026] Production of liquid crystal cell: Cut the glass coated with indium tin oxide on one side into a size of 2cm×3cm, wash it twice with washing powder, clean water, deionized water and ethanol each, place it in a clean glass petri dish, and dry it for later use. Weigh 100 mg of ZIF-8 in a round-bottomed flask containing 100 ml of methanol with magnetic stirring and ultrasonication for 1 hour. After standing for 12 hours, it was centrifuged, washed and filtered with methanol. . Put the processed ZIF-8 into an ampoule, then connect the vacuum pump through the connector, and use the vacuum pump to draw out the air, so that the inside of the device is in a vacuum state for 10 minutes. Weigh 120 mg of the chiral dopant R5011 and 60 mg of the ultraviolet absorbing dye UV-327, respectively add them into two 20 mL portions of ethyl acetate to obtain a mixed solution, and use ultrasonic vibration to mix uniformly. Then two parts of 40 mg of vacuum-treated ZIF-8 were placed in the eth

Embodiment example 2

[0042] Production of liquid crystal cell: The ZIF-8 / R5011 composite material and the ZIF-8 / UV-327 composite material in Example 1 were mixed with methanol to prepare a 6 mg / ml mixed solution and mixed uniformly. 0.1ml of the mixed solution was evenly drop-coated on the treated glass substrate. After the drop-coating, it was dried on a hot table and evaporated to obtain a composite film containing ZIF-8 / UV-327 and ZIF-8 / R5011. Material thin glass substrate. Then, the liquid crystal cell was assembled in the same manner as in Example 1, and then stored in a 60° C. oven.

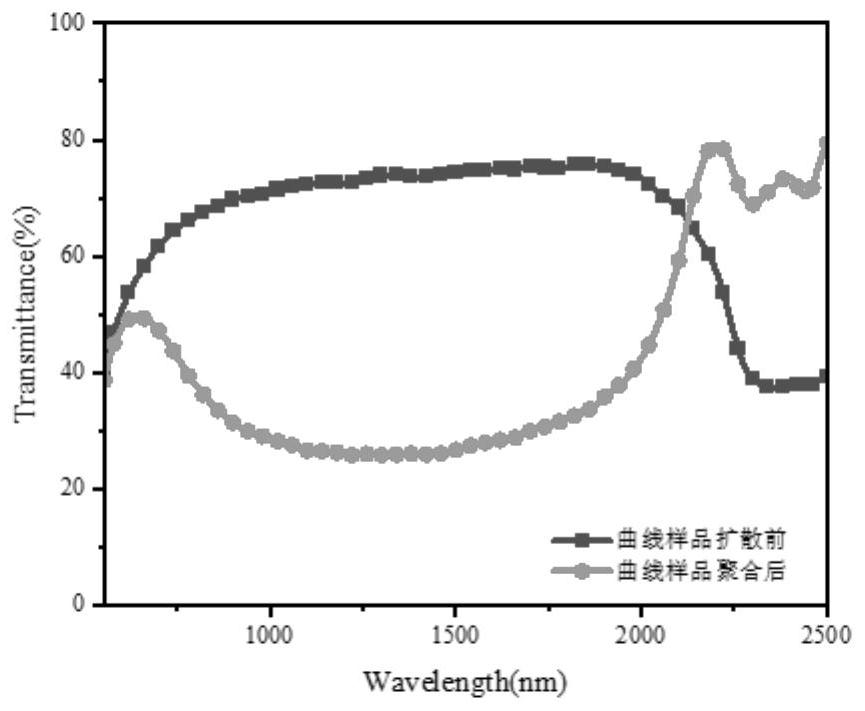

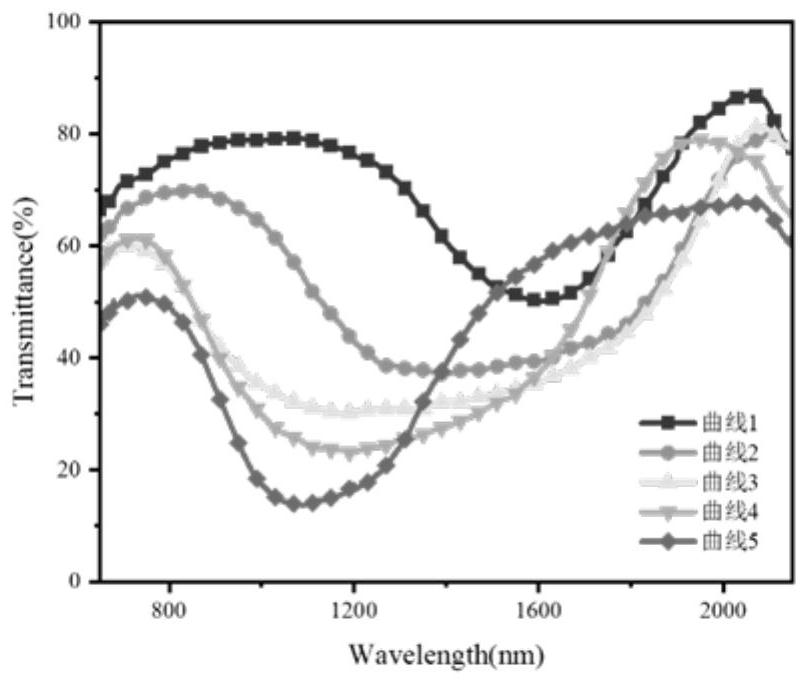

[0043] Sample 2 was obtained according to the mass ratio and diffusion and polymerization conditions of the liquid crystal system in Example 1, and the polymerizable monomer was cured and crosslinked to form a network to obtain the final polymer network cholesteric liquid crystal film. The transmission spectrum of the sample can be measured at room temperature using an ultraviolet-visible-near-infrared

Embodiment example 3

[0045] Production of liquid crystal cell: The ZIF-8 / R5011 composite material and the ZIF-8 / UV-327 composite material in Example 1 were mixed with methanol to prepare a mixed solution of 8 mg / ml and mixed uniformly. 0.1ml of mixed solution was evenly drop-coated on the treated glass substrate, used after drip-coating, dried on a hot table, and after volatilizing the solvent, a film containing ZIF-8 / UV-327 composite material and ZIF-8 / R5011 composite material were prepared. Material thin glass substrate. Then, the liquid crystal cell was assembled in the same manner as in Example 1, and then stored in a 60° C. oven.

[0046] Sample 3 was obtained according to the mass ratio of the liquid crystal system and the polymerization conditions in Example 1, and the polymerizable monomer was cured and crosslinked to form a network to obtain the final polymer network cholesteric liquid crystal film. The transmission spectrum of the sample can be measured at room temperature using

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap