Modified nano magnesium hydroxide flame retardant and preparation method thereof

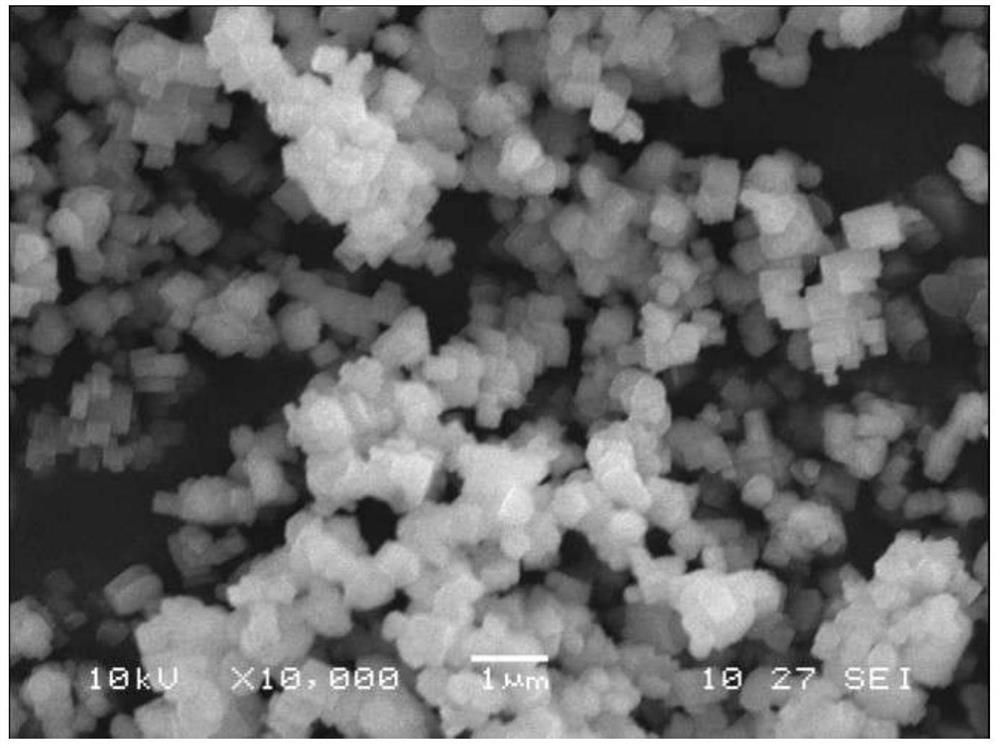

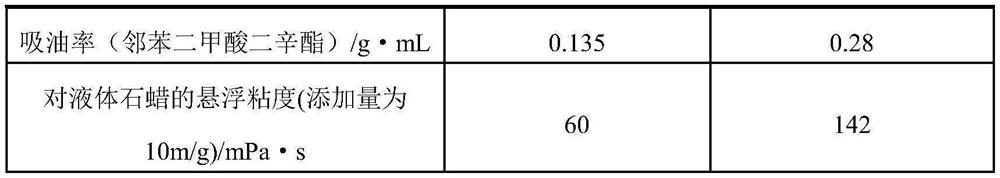

A nano-magnesium hydroxide and flame retardant technology is applied in the field of preparation of functional materials, which can solve problems such as poor compatibility and decline in mechanical properties of polymer materials, and achieve improved mechanical properties, superior flame retardant properties, and good dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 30.0g of magnesium chloride, completely dissolve it in deionized water, prepare a solution with a concentration of 0.02mol / L, dissolve 4.0g of silane coupling agent 702 in solvent water, and prepare a concentration of 0.02mol / L. The good magnesium chloride solution and silane coupling agent 702 are then transferred to the storage bottle of the microchannel reactor pipeline 1 for use. It should be noted that the microchannel reactor used in this embodiment can be a circular microreaction channel or The wave-shaped micrograph reaction channel is not limited in this embodiment, and the following embodiments are the same as above; weigh 20.0g of sodium hydroxide, prepare a sodium hydroxide solution with a concentration of 0.05mol / L, and place it in the microchannel reactor pipeline Two storage bottles for later use. At 30°C and 0.5MP pressure, the mixed solution of magnesium chloride and silane coupling agent 702 was input into the microchannel reactor at 2 mL / mi

Embodiment 2

[0025] Weigh 80.0g of magnesium chloride, completely dissolve it in deionized water, prepare a solution with a concentration of 0.04mol / L, dissolve 4.0g of silane coupling agent 702 in solvent water, and prepare a concentration of 0.04mol / L. The good magnesium chloride solution and silane coupling agent 702 are then transferred to the storage bottle of the microchannel reactor pipeline 1 for use; 10.0g of sodium hydroxide is weighed to prepare a sodium hydroxide solution with a concentration of 0.025mol / L , placed in the storage bottle of the second pipeline of the microchannel reactor for use. At 25°C and 1MP pressure, the mixed solution of magnesium chloride and coupling agent was fed into the microchannel reactor at 2 mL / min and the sodium hydroxide solution at 6 mL / min for the reaction. After the reaction, it was washed three times with deionized water and filtered with suction. After suction filtration, it is naturally dried to obtain modified magnesium hydroxide

Embodiment 3

[0030] Weigh 80.0g of magnesium chloride, completely dissolve it in deionized water, prepare a solution with a concentration of 0.04mol / L, dissolve 4.0g of silane coupling agent 702 in solvent water, and prepare a concentration of 0.04mol / L. The amount of coupling agent added is 0.5% of magnesium chloride, and the prepared magnesium chloride solution and silane coupling agent 702 are then transferred to the storage bottle of the microchannel reactor pipeline 2 for use; 10.0g of sodium hydroxide is weighed, A sodium hydroxide solution with a concentration of 0.025 mol / L was prepared and placed in the storage bottle of pipeline 2 of the microchannel reactor for use. At 30°C and 1MP pressure, the mixed solution of magnesium chloride and coupling agent was fed into the microchannel reactor at 2 mL / min and the sodium hydroxide solution at 6 mL / min for the reaction. After the reaction, it was washed three times with deionized water and filtered with suction. After suction fi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap