Technological installation matched with cooling pipe type low pressure synthesis tower

A technology of process equipment and synthesis tower, which is applied in the preparation of organic compounds, preparation of hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of insufficient utilization of catalysts, differences in catalyst activity, and large consumption of catalysts, etc. Achieve catalyst activity protection, facilitate reaction, and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

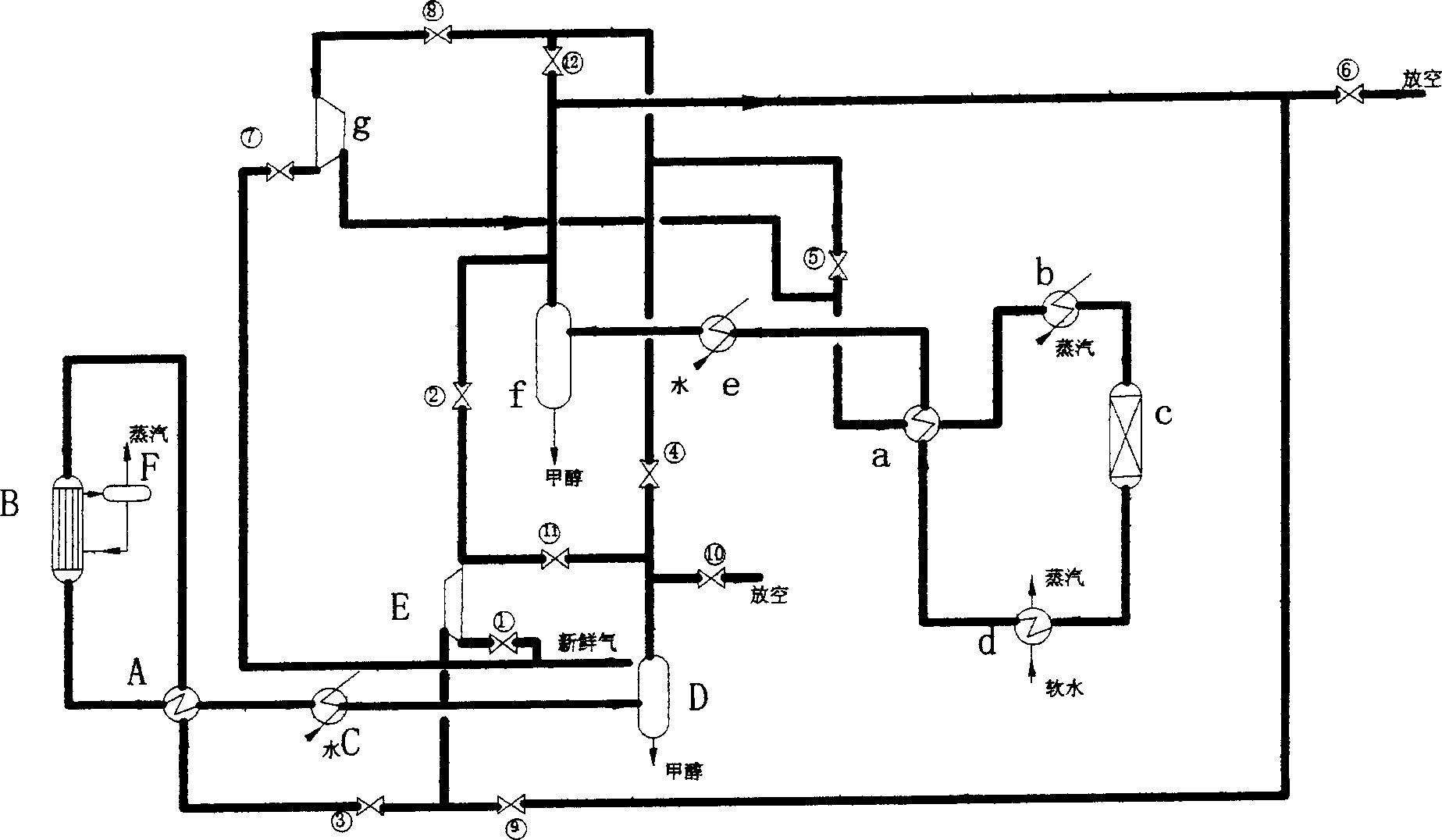

[0016] Combine below figure 2 The present invention is further described.

[0017] The low-pressure methanol synthesis device of the shell-and-tube synthesis tower system of the present invention consists of a heat exchanger (A), a shell-and-tube synthesis tower (B), a water cooler (C), an alcohol separator (D), a circulator (E) and a steam drum (F) consists of an independent production system connected by corresponding pipes and valves.

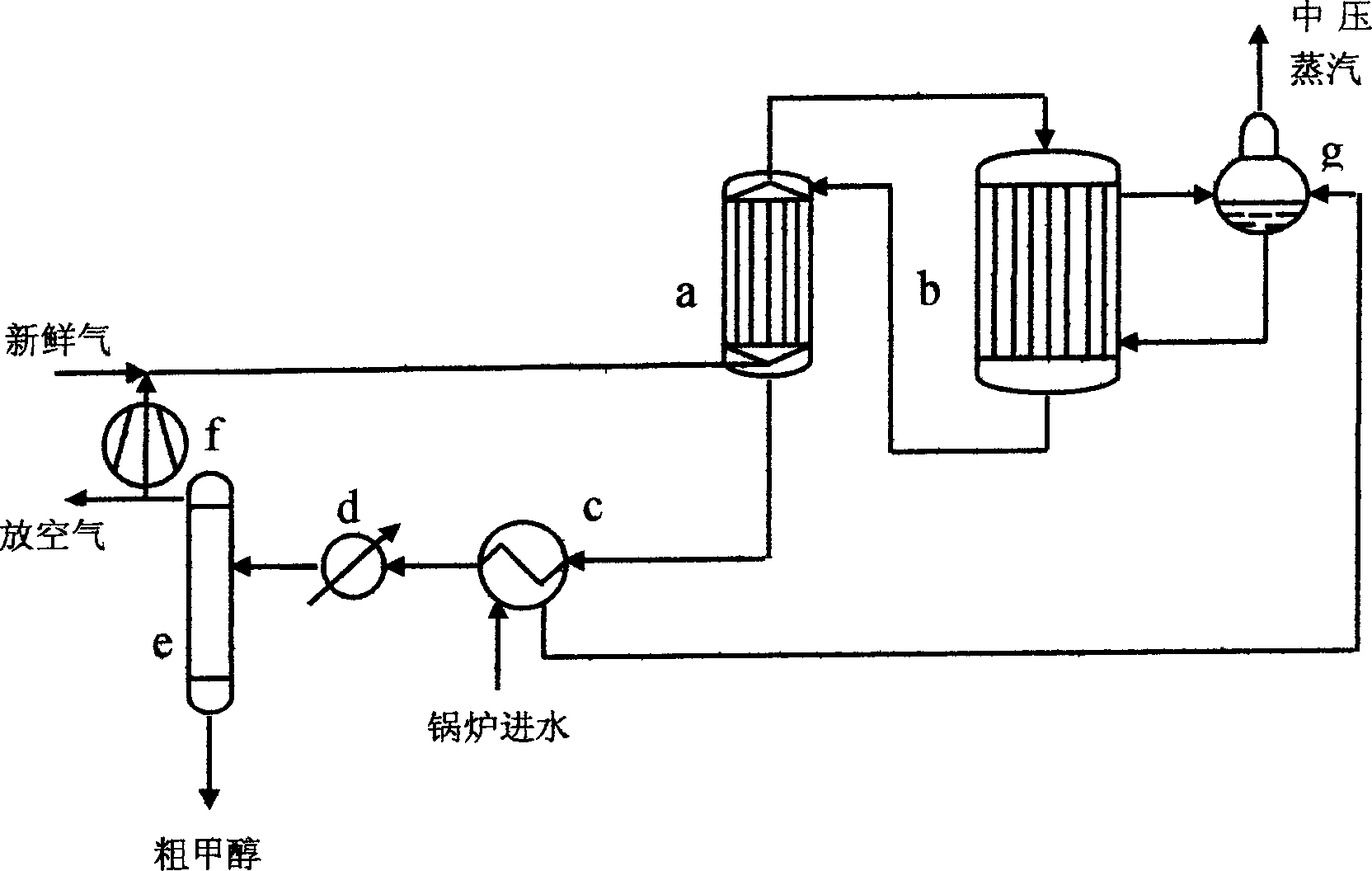

[0018] The low-pressure synthesis device of the cold tube type synthesis tower system of the present invention consists of a heat exchanger (a), a steam heater or an electric heater (b), a cold tube type synthesis tower (c), a waste heat boiler (d), and a water cooler (e). , an alcohol separator (f) and a circulation machine (g), connected by corresponding pipelines and valves to form an independent production system.

[0019] Adding some pipelines and valves can make the two systems into a series or parallel device, and the front and rear s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap