Shaft drive for loom shafts

A technology of transmission device and drive device, which is applied in looms, textiles, dobbies, etc., can solve the problem of inflexibility of cam machines and achieve the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

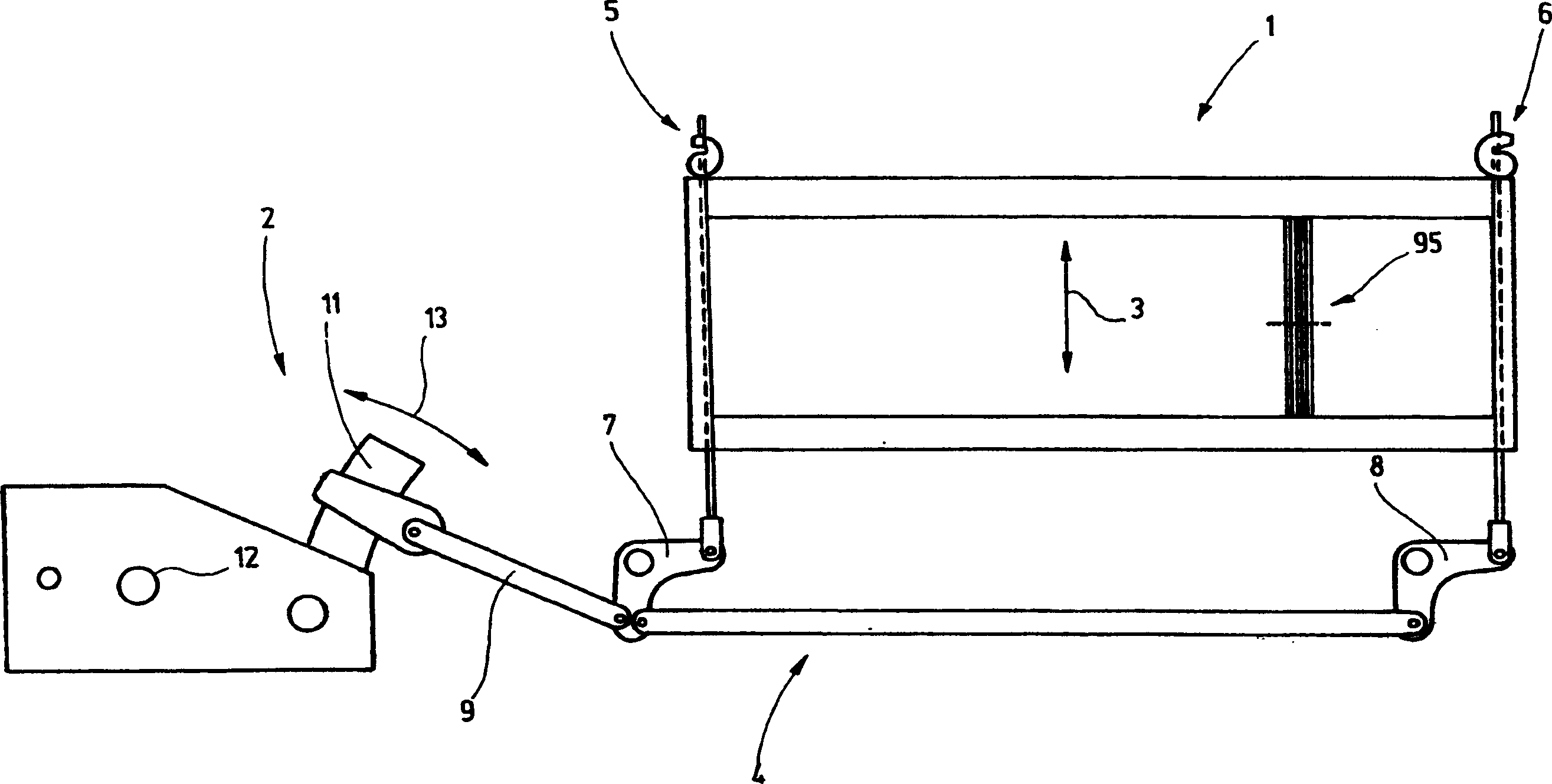

[0032] figure 1 The heald frame 1 and the associated heald frame transmission 2 are shown. The heald frame 1 is composed of a frame with a wire heald 95, and the frame moves up and down as indicated by the arrow 3 during the work. For transmission, a connecting rod 4 is used, which is connected to two or more parts 5 and 6 of the heald frame 1 and constitutes the output device of the heald frame transmission device 2. There are toggle levers 7, 8 belonging to the connecting rod 4. The toggle lever is connected to the heald frame 1 on the one hand and directly or indirectly with the tie rod and the pressure rod 9 on the other hand. The pull rod and the pressure rod are connected to the heald frame transmission 2, which for this purpose has a pendulum rod 11 that follows the swing motion at the output end. The heald frame transmission 2 is generated from the uniform rotational movement of the input shaft 12 figure 1 The reciprocating movement indicated by the arrow 13 is indicated b

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap