Flex-fuel variable displacement engine control system and method

a variable-distance engine and control system technology, applied in the direction of electric control, machines/engines, instruments, etc., can solve the problems of limited vde operation window, possible modest fuel economy gains, and limited potential fuel economy gains, so as to improve performance, extend vde operation, and expand vde operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

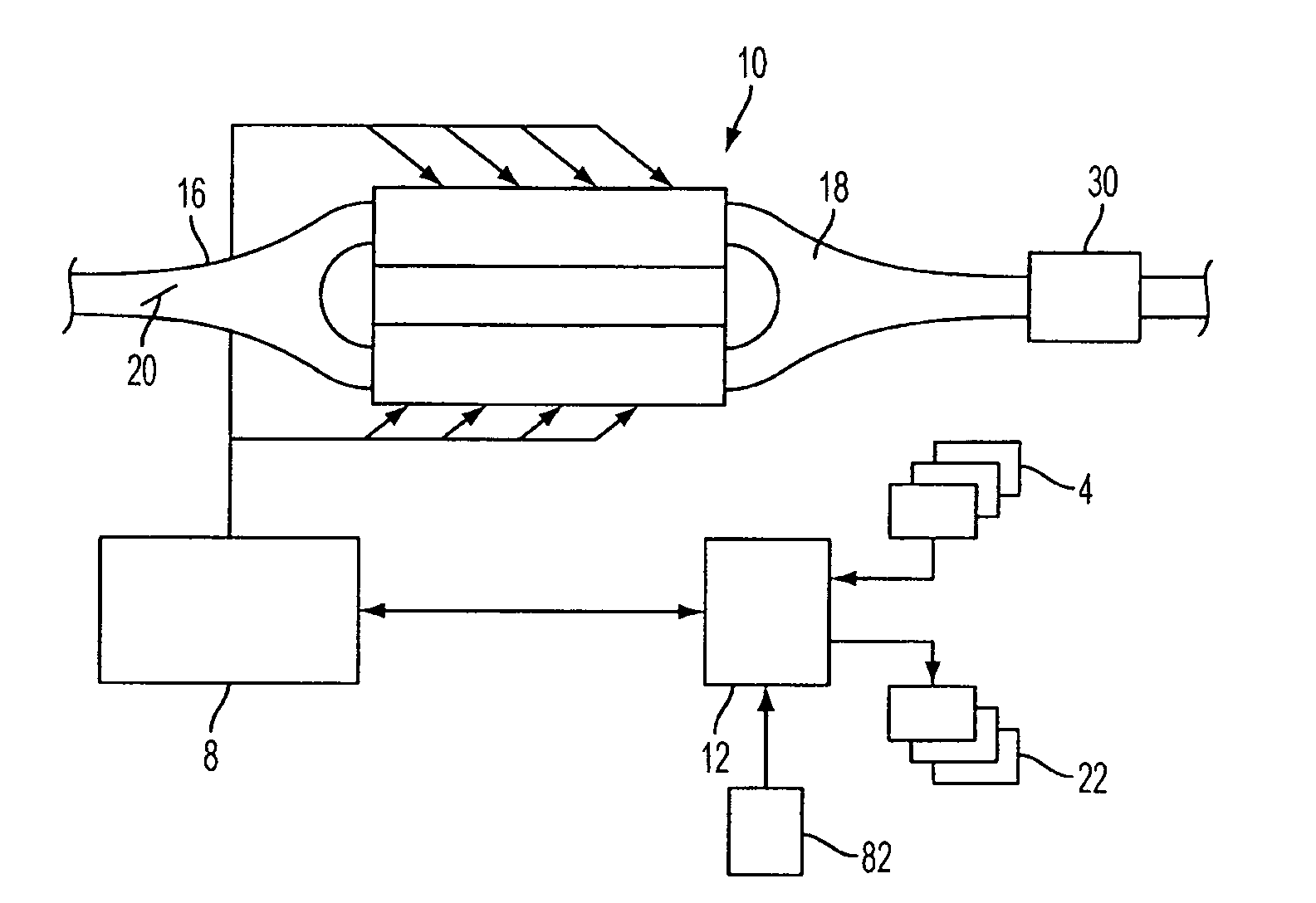

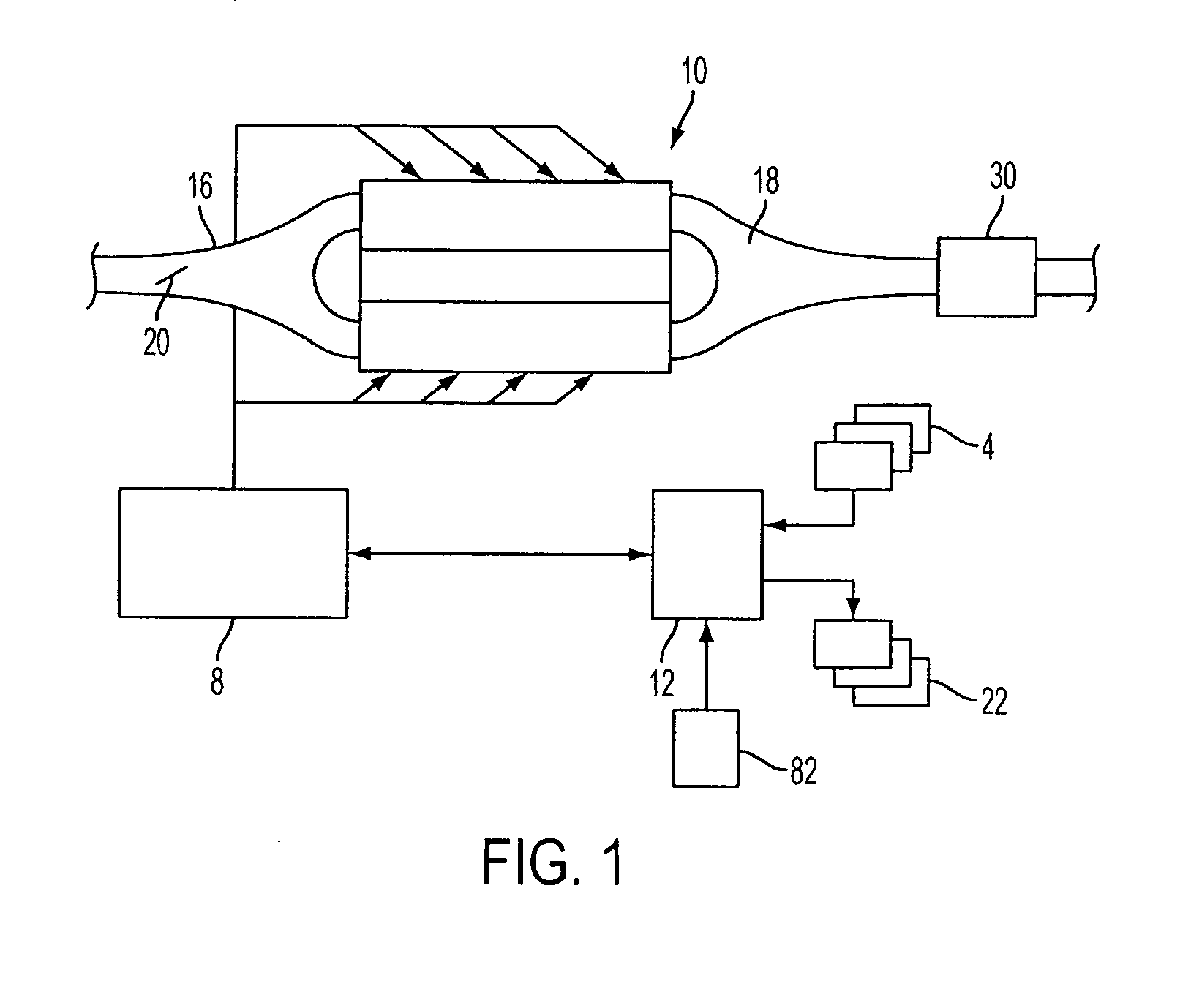

[0013]FIG. 1 shows an example variable displacement engine (VDE) 10, in which four cylinders (e.g., two in each bank) may have cylinder valves held closed during one or more engine cycles. The cylinder valves may be deactivated via hydraulically actuated lifters coupled to valve pushrods, or via a cam profile switching mechanism in which a cam lobe with no lift is used for deactivated valves. Still other valve deactivation mechanisms may also be used, such as electrically actuated valves.

[0014]Engine 10 may operate on a plurality of substances, which may be delivered via fuel system 8. Fuel system 8 may include various tanks, alcohol separator units, control and / or mixing valves, and injectors as described in more detail herein. Specifically, the various substances in fuel system 8 may include multiple different fuel blends, injection locations, or various other alternatives. In one example, multiple different substances having different gasoline and / or alcohol and / or water conce

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap