Liquid crystal display device and fabrication method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

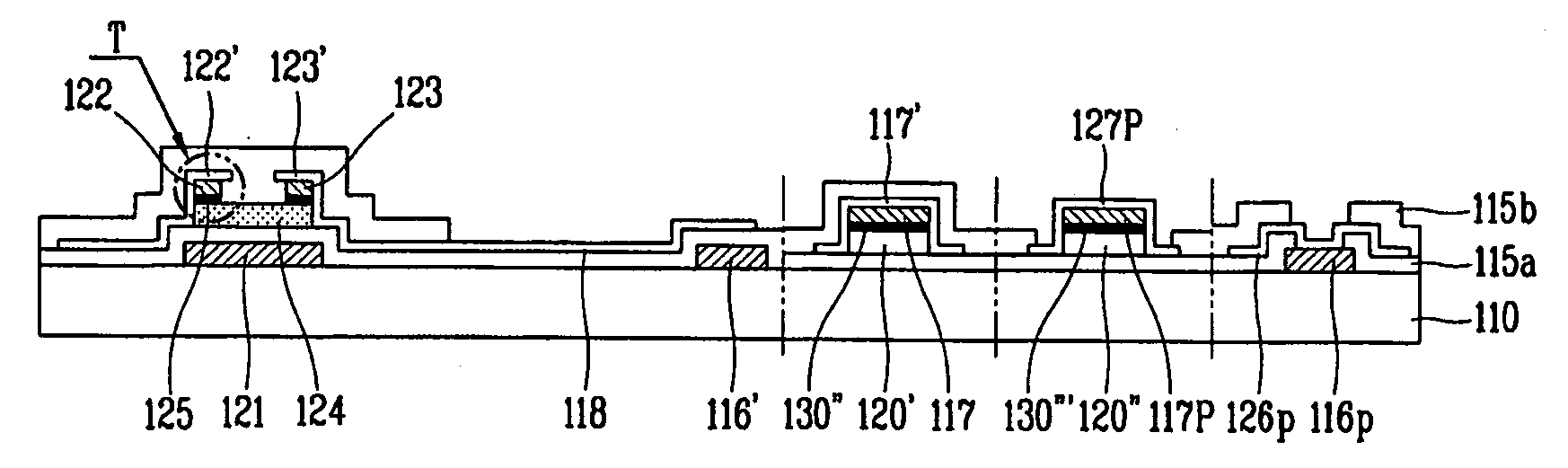

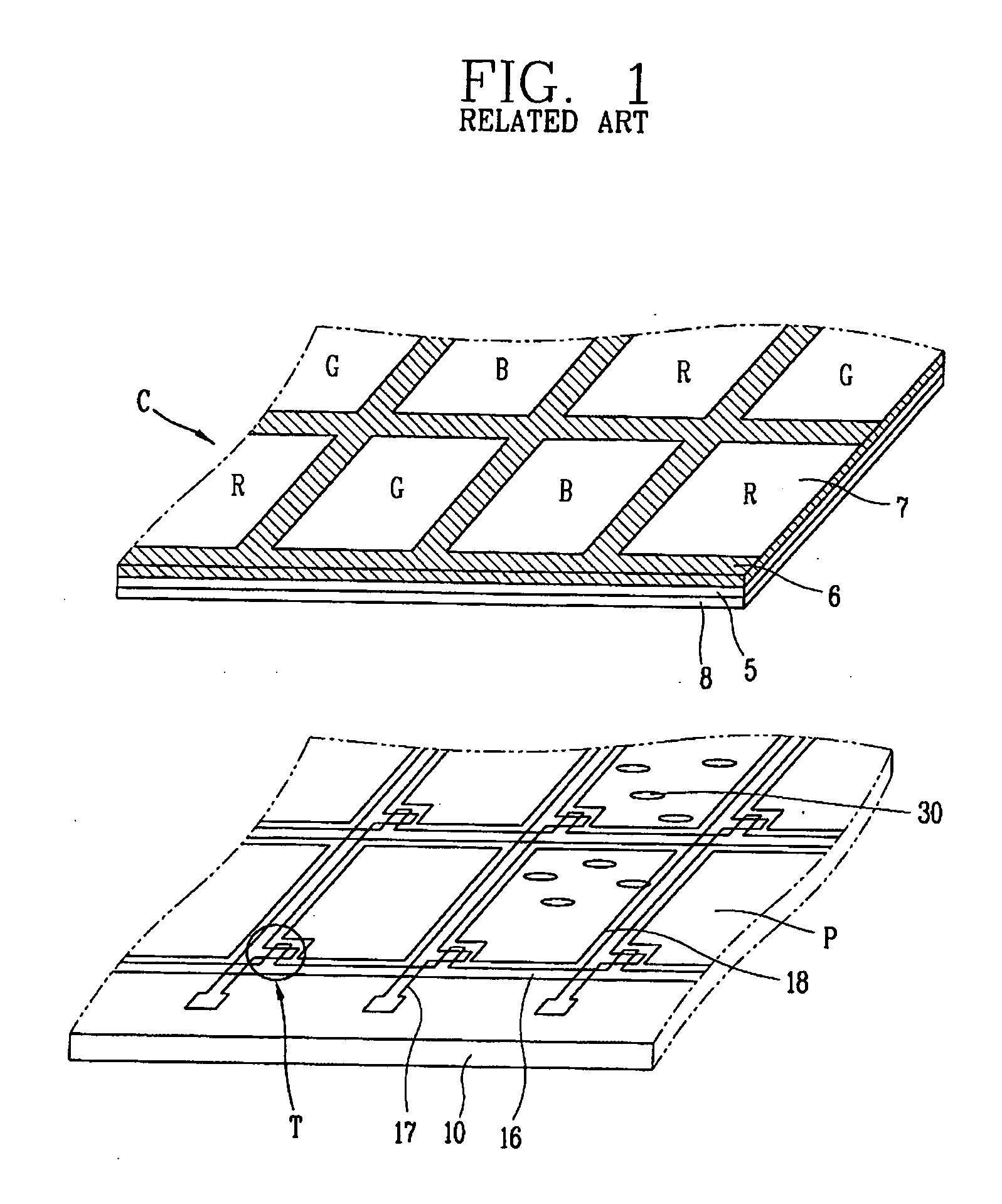

[0053]FIG. 3 is a plan view showing a portion of an array substrate of an LCD according to the present invention, in which a single pixel including a gate pad part and a data pad part are shown for the sake of explanation.

[0054]FIG. 4 is a view illustrating an enlarged portion ‘A’ of the array substrate in FIG. 3.

[0055]Actually, the N number of gate lines and the M number of data lines are formed to cross each other to define the M×N number of pixels. To simplify the explanation, only a single pixel is shown.

[0056]As shown in FIGS. 3 and 4, on an array substrate 110 according to a first embodiment of the present invention, gate lines 116 and the data lines are formed to be arranged vertically and horizontally to define the pixel region. A thin film transistor (TFT), a switching element, is formed at a crossing of the gate line 116 and the data line 117. A pixel electrode 118 is formed within the pixel region, is connected with the TFT to drive liquid crystal (not shown) together with a

second embodiment

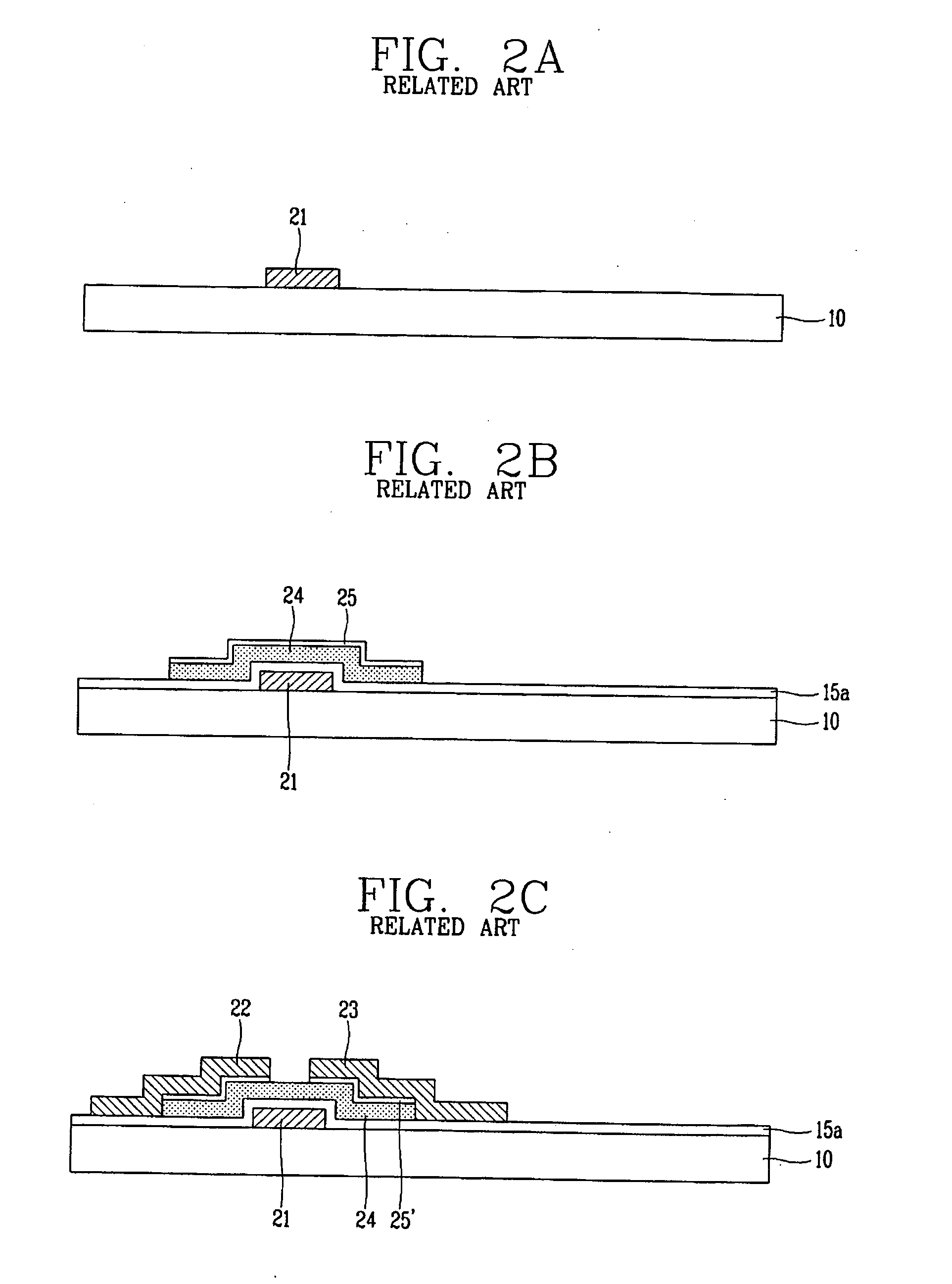

[0114]In order to improve this structure, the photosensitive film pattern is collapsed through a baking process after the first wet etching to cover the upper conductive film pattern, and then, the second wet etching is performed to thus prevent the occurrence of the above-mentioned undercut phenomenon and form a forward taper shape. This will now be described in detail through the present invention.

[0115]FIGS. 9A to 9E are cross-sectional views sequentially showing an etching process in the two-metal stacked structure according to a second embodiment of the present invention.

[0116]As shown in FIG. 9A, a first conductive film 260 and a second conductive film 265 are stacked on an array substrate 210, and then, a first photosensitive film pattern 275 made of a photosensitive material such as photoresist is formed thereon.

[0117]Thereafter, as shown in FIG. 9B, the lower second conductive film is selectively removed by using the first photosensitive film pattern 275 as a mask (a first wet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap