Probe assembly, method of producing it and electrical connecting apparatus

a technology of electrical connection and assembly method, which is applied in the manufacture of contact parts, instruments, printed circuits, etc., can solve the problems of difficult adjustment to make such numerous probes, complicated work of adjusting to make all the probe tips contact properly with each corresponding electrical connection terminal of the device under test, and difficulty in making such numerous probes. , to achieve the effect of convenient production, efficient electrical testing and easy formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

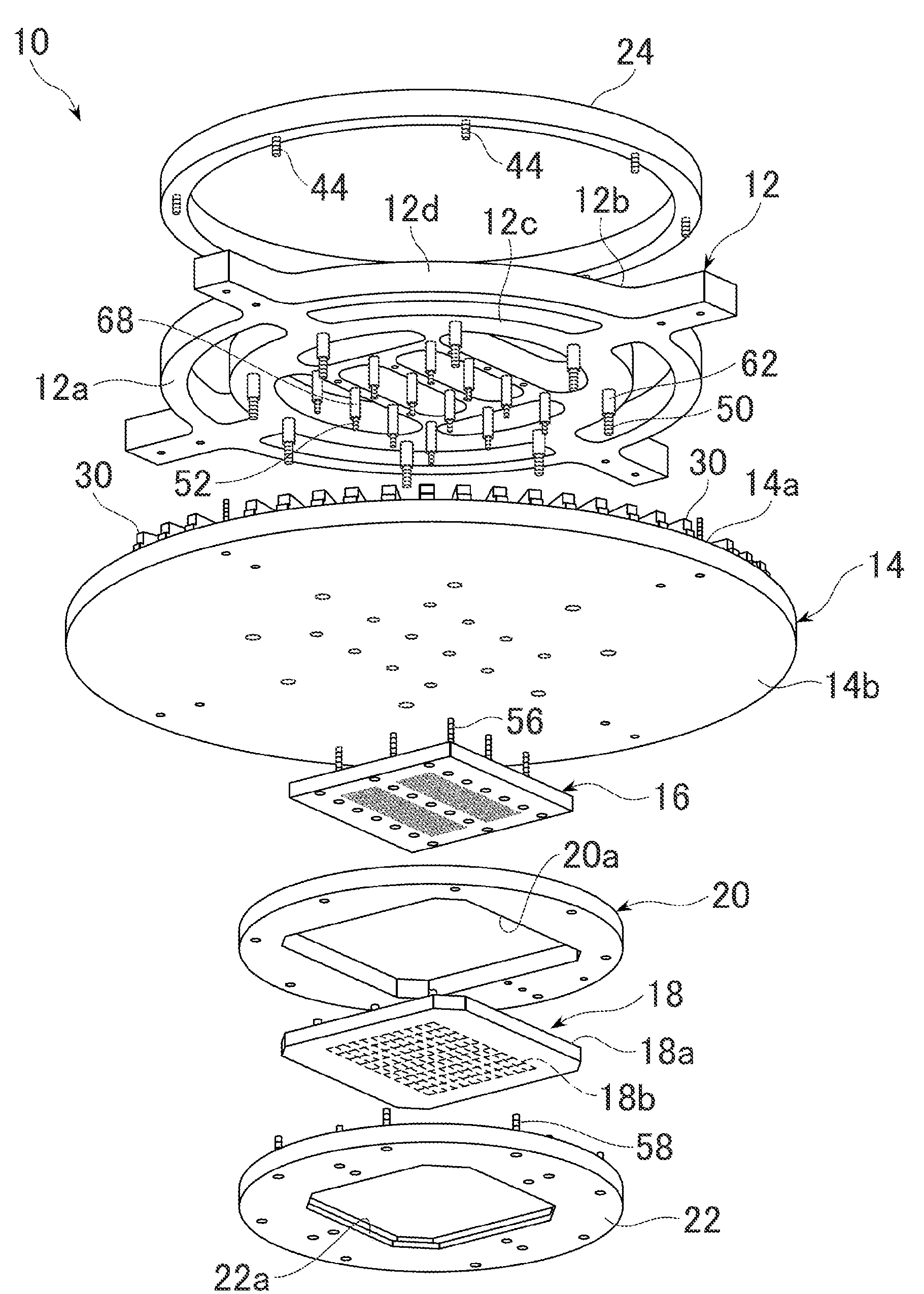

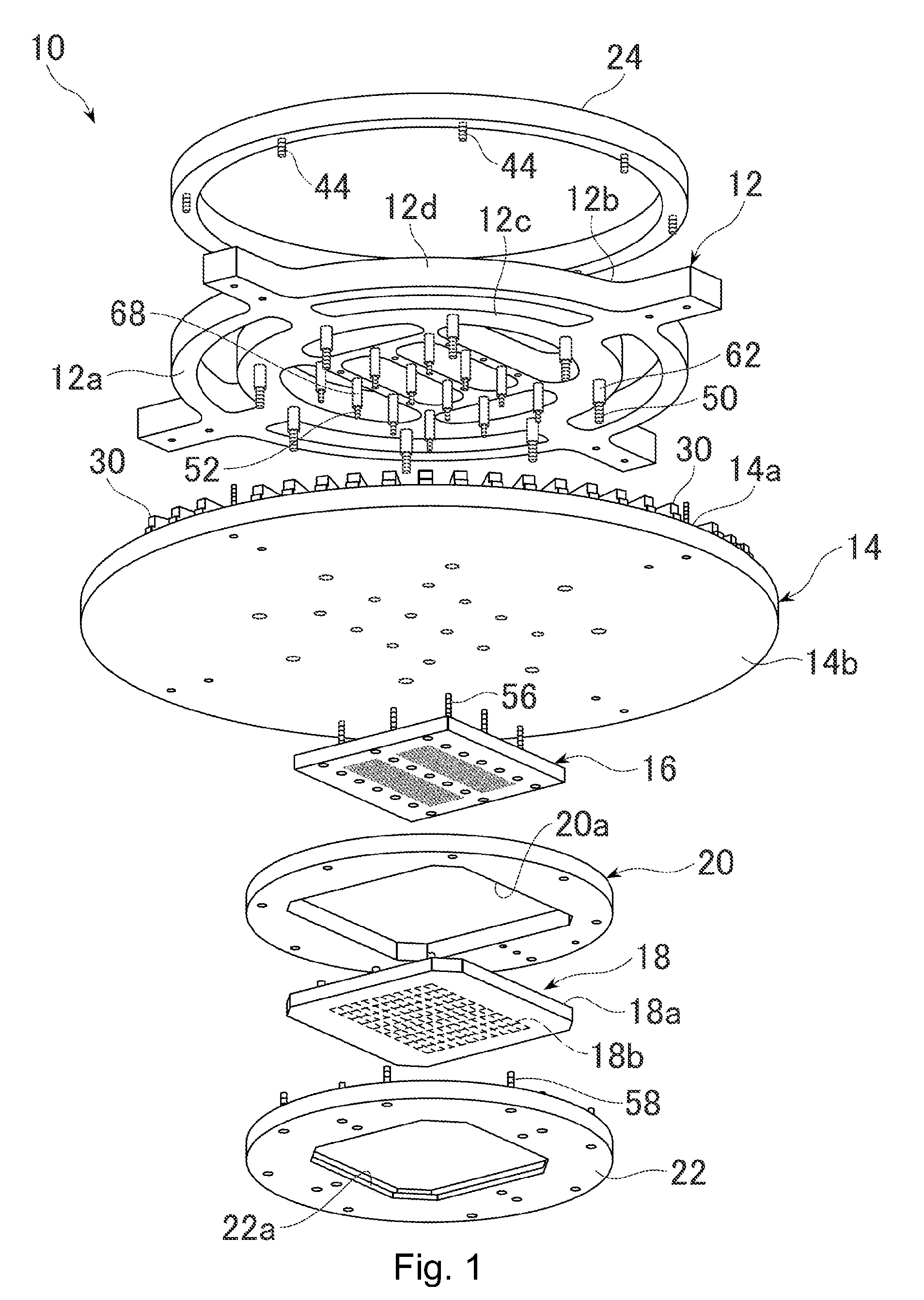

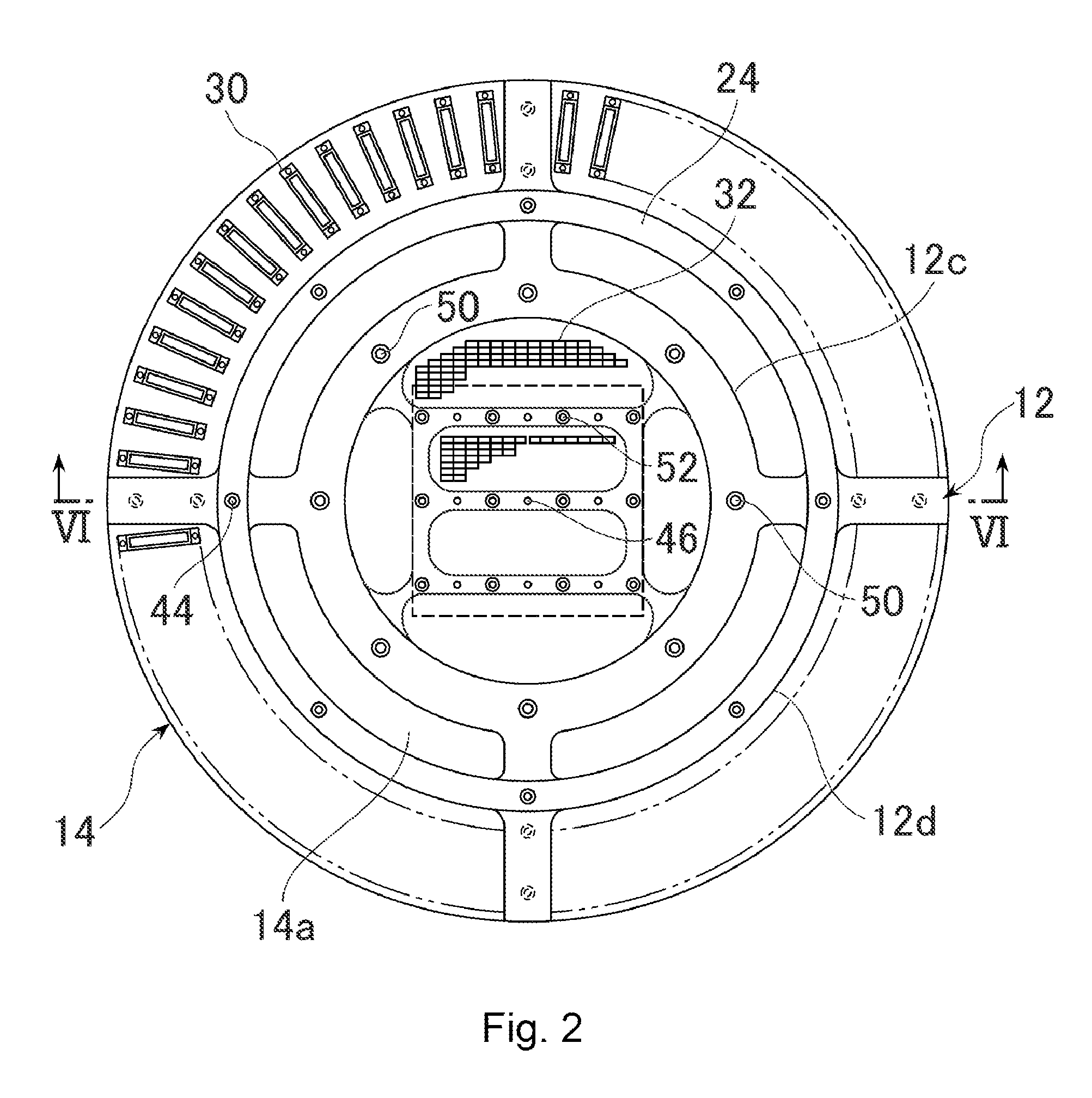

[0066]The electrical connecting apparatus 10 according to the present invention is shown in FIG. 1 in an exploded state. This electrical connecting apparatus 10 comprises: a flat plate-like supporting member 12, the underside 12a of which becomes a flat mounting reference plane; a circular flat plate-like wiring base plate 14 held by the mounting plane 12a of the supporting member; a probe assembly 18 electrically connected with the wiring base plate 14 through an electrical connector 16; a base ring 20 with a central opening 20a formed for receiving the electrical connector 16; and a securing ring 22 for sandwiching the edge portion of the probe assembly 18 in cooperation with the edge portion of the central opening 20a of the base ring. This securing ring 22 has in its central portion a central opening 22a permitting probes 18b mentioned later of the probe assembly 18 to be exposed. In the illustration, a thermal deformation inhibitor 24 for restraining a thermal deformation of the s

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap