Inline vacuum processing apparatus, method of controlling the same, and information recording medium manufacturing method

a vacuum processing and vacuum technology, applied in the direction of plasma technique, metal material coating process, coating, etc., can solve the problems of affecting the production efficiency of the entire production line, so as to shorten the time of carbon protective film formation and improve the production efficiency without bulky and expensive apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Preferred embodiments of the present invention will now be described exemplarily in detail with reference to the accompanying drawings. Note that the constituent elements described in the embodiments are merely examples. The technical scope of the present invention is determined by the scope of claims and is not limited by the following individual embodiments.

[0043]The production line of an information recording medium (to be referred to as an “information recording disk” hereinafter) includes a load lock chamber to mount a substrate on a carrier, an unload lock chamber to unload the substrate from the carrier, and chambers to execute a plurality of manufacturing processes. The chambers are connected in series and arranged in a line or in a rectangular form, thereby forming an information recording disk production line.

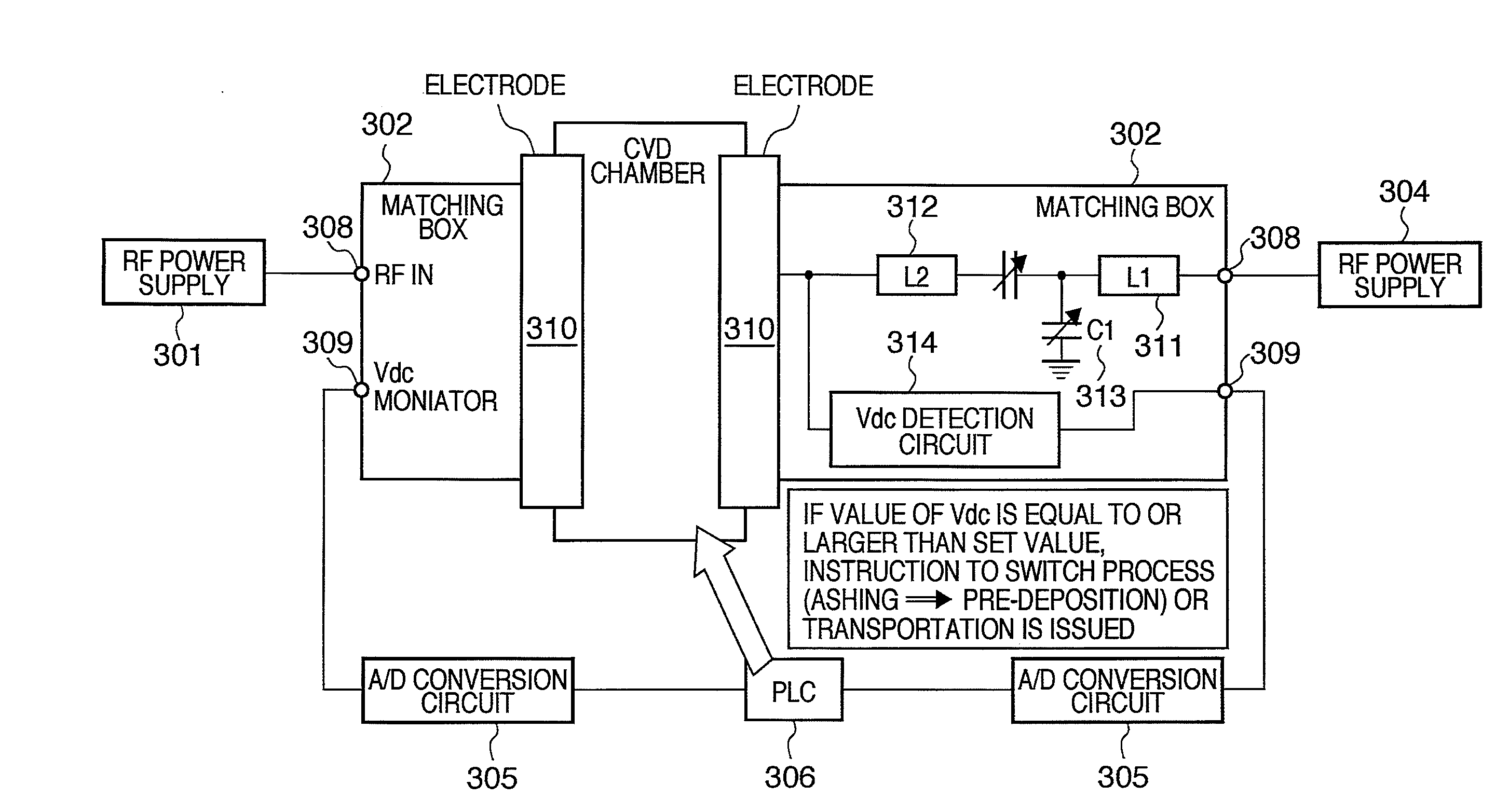

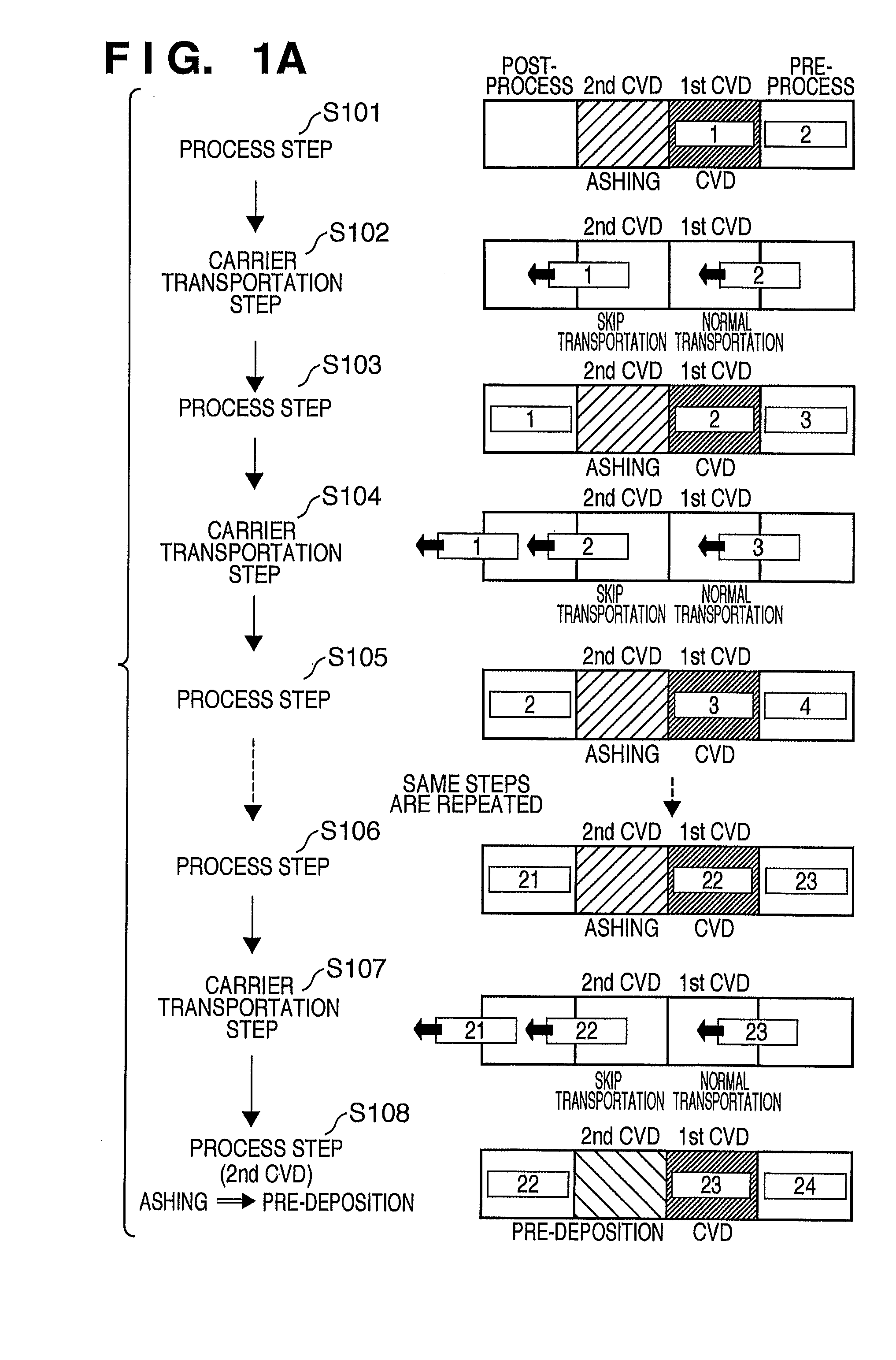

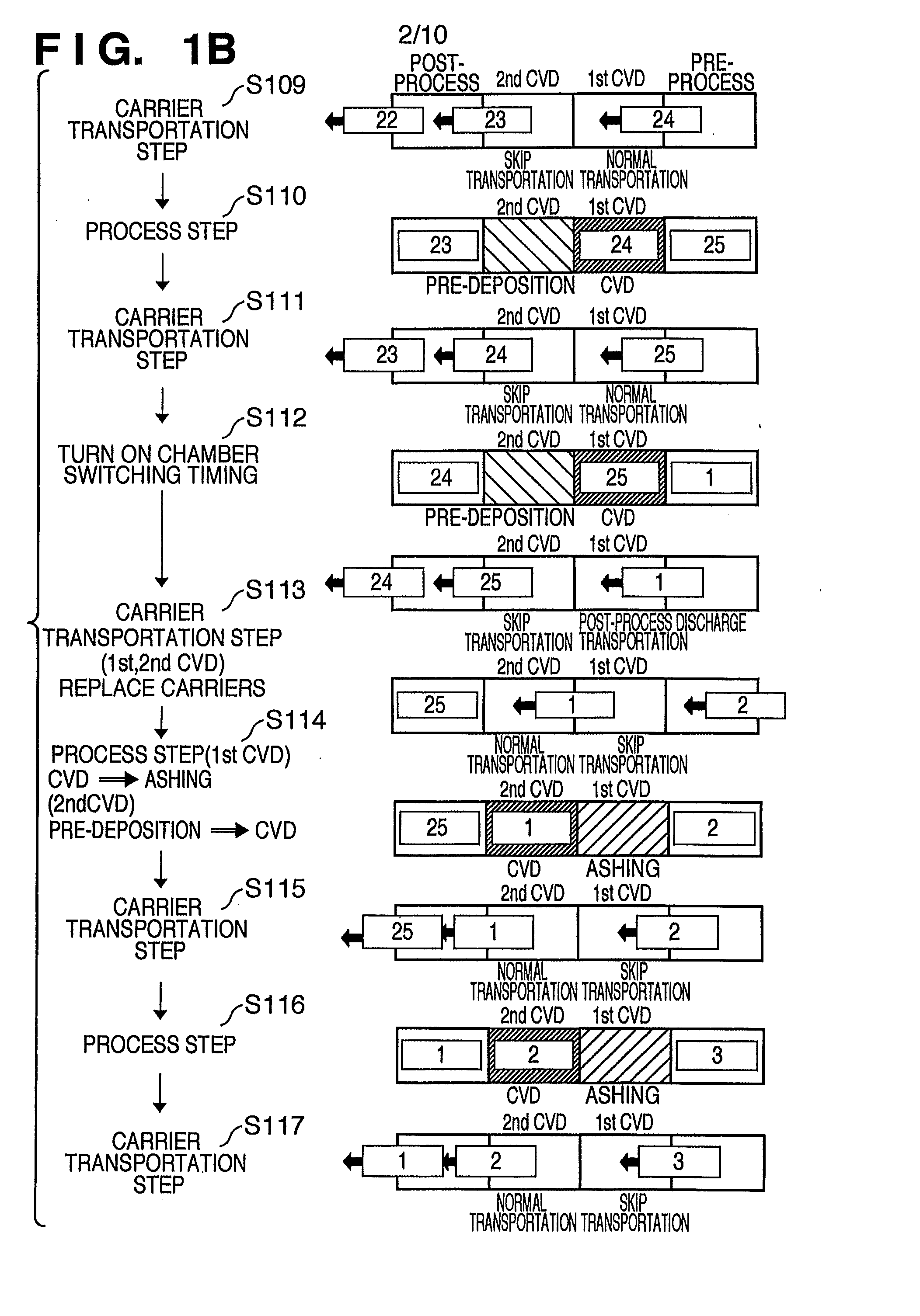

[0044]FIGS. 1A to 1C are schematic views showing a partial arrangement of an inline vacuum processing apparatus according to the embodiment of the present inventio

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap