Physical quantity sensor, electronic device, and method of manufacturing physical quantity sensor

a technology of physical quantity sensor and electronic device, which is applied in the direction of electrical transducers, microstructural devices, instruments, etc., can solve the problems of poor area efficiency, increased chip area, and inferior resistance values to metals, and achieves low impedance and a lot of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Overall Configuration of Capacitive Acceleration Sensor

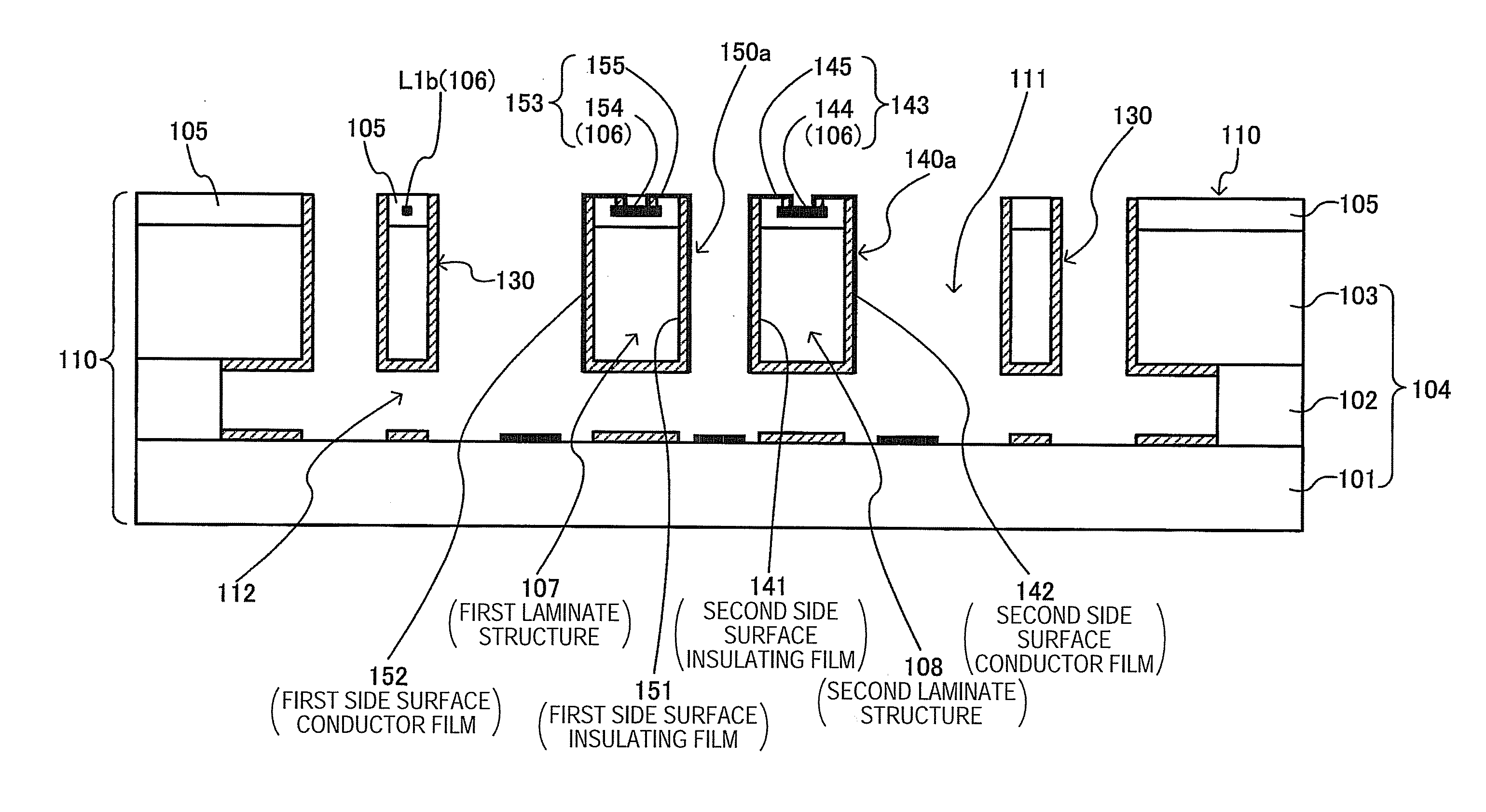

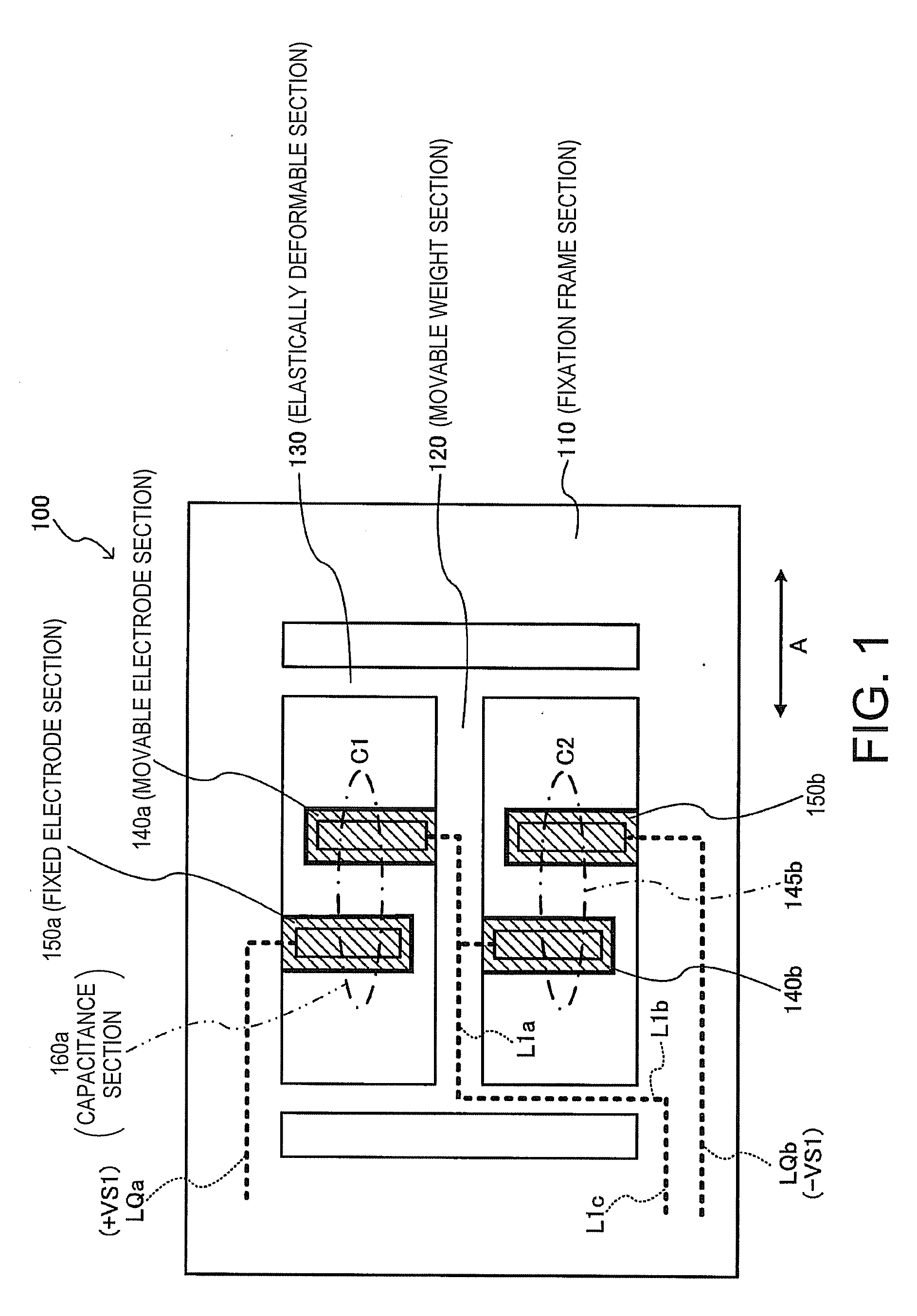

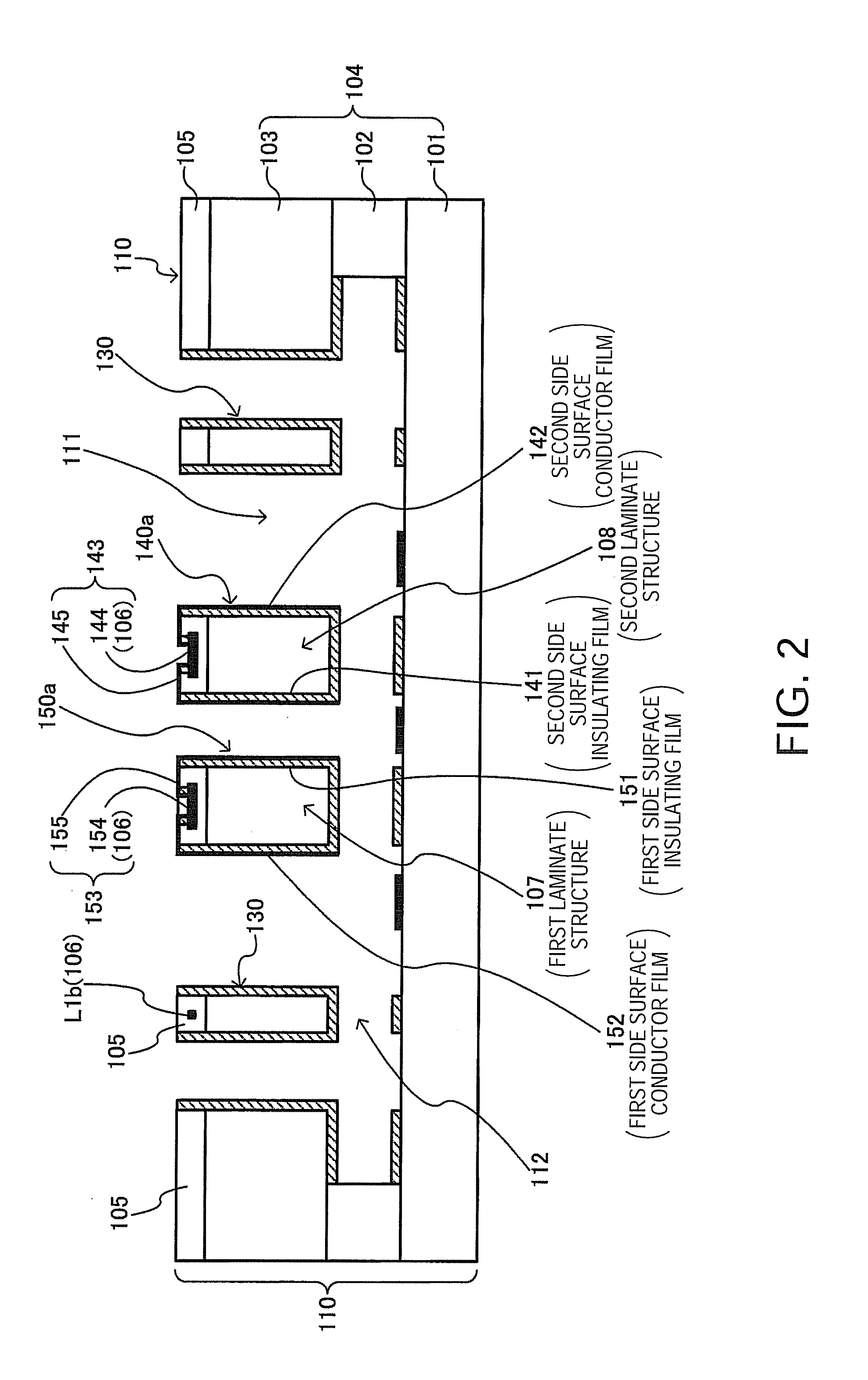

[0054]FIG. 1 is a plan view showing a configuration of an example (assumed here to be a capacitive acceleration sensor) of a MEMS sensor as a physical quantity sensor according to an embodiment of the invention. FIG. 2 is a cross-sectional view of the capacitive acceleration sensor shown in FIG. 1. FIG. 3 is a partial enlarged view of electrode sections 140, 150 shown in FIG. 2. It should be noted that the planar layout shown in FIG. 1 is illustrated as the simplest example, and in the present embodiment, the planar layout with high area efficiency shown in FIG. 13 can be adopted.

[0055]The capacitive acceleration sensor 100 shown in FIGS. 1 and 2 can be manufactured by forming a laminate structure on a substrate, and then selectively processing the laminate structure using a semiconductor manufacturing technology. For example, there can be used an SOI substrate 104 obtained by stacking an intermediate layer 102 (SiO2; referred also

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap