Turbocharger and Variable-Nozzle Cartridge Therefor

a variable-nozzle, turbocharger technology, applied in the direction of positive displacement liquid engines, liquid fuel engines, piston pumps, etc., can solve the problems of reducing the efficiency of the turbine and hence the overall performance of the turbocharger, and the clearance effect is particularly harmful at low engine speed, so as to achieve the effect of reducing the performance penalty due to the clearance of the vane at low engine speed and achieving the effect of performance benefi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The present inventions now will be described more fully hereinafter with reference to the accompanying drawings, in which some but not all embodiments of the inventions are shown. Indeed, these inventions may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will satisfy applicable legal requirements. Like numbers refer to like elements throughout.

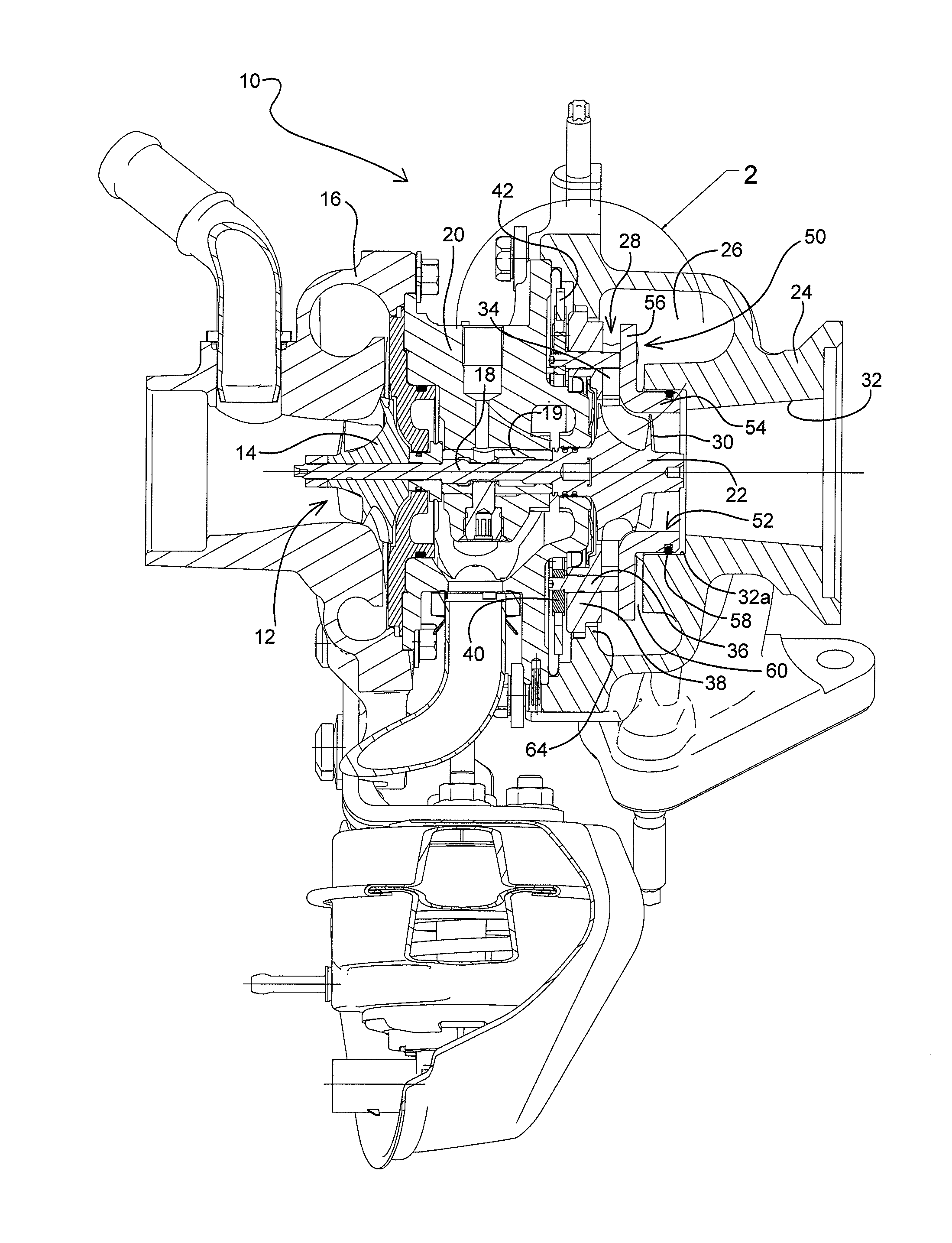

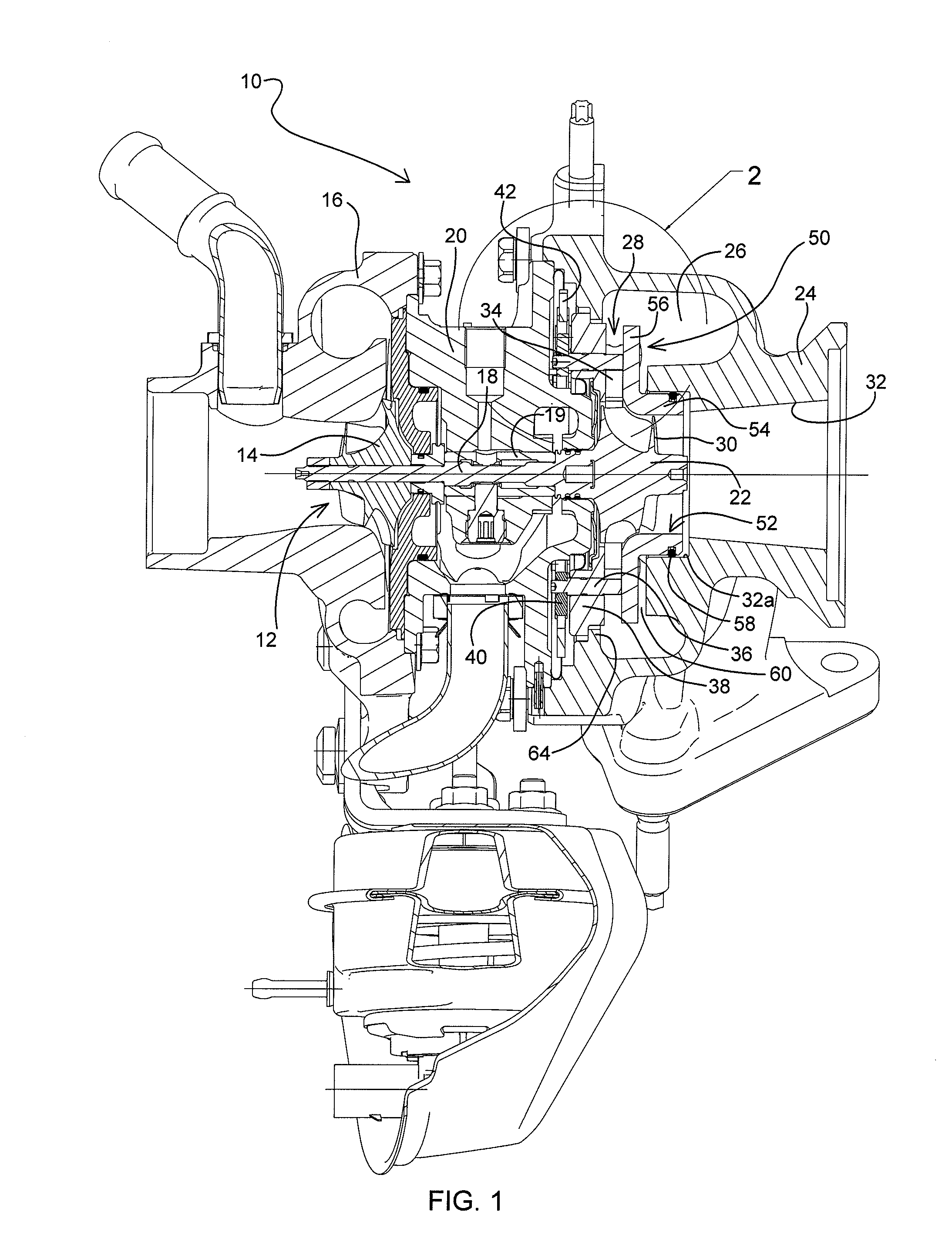

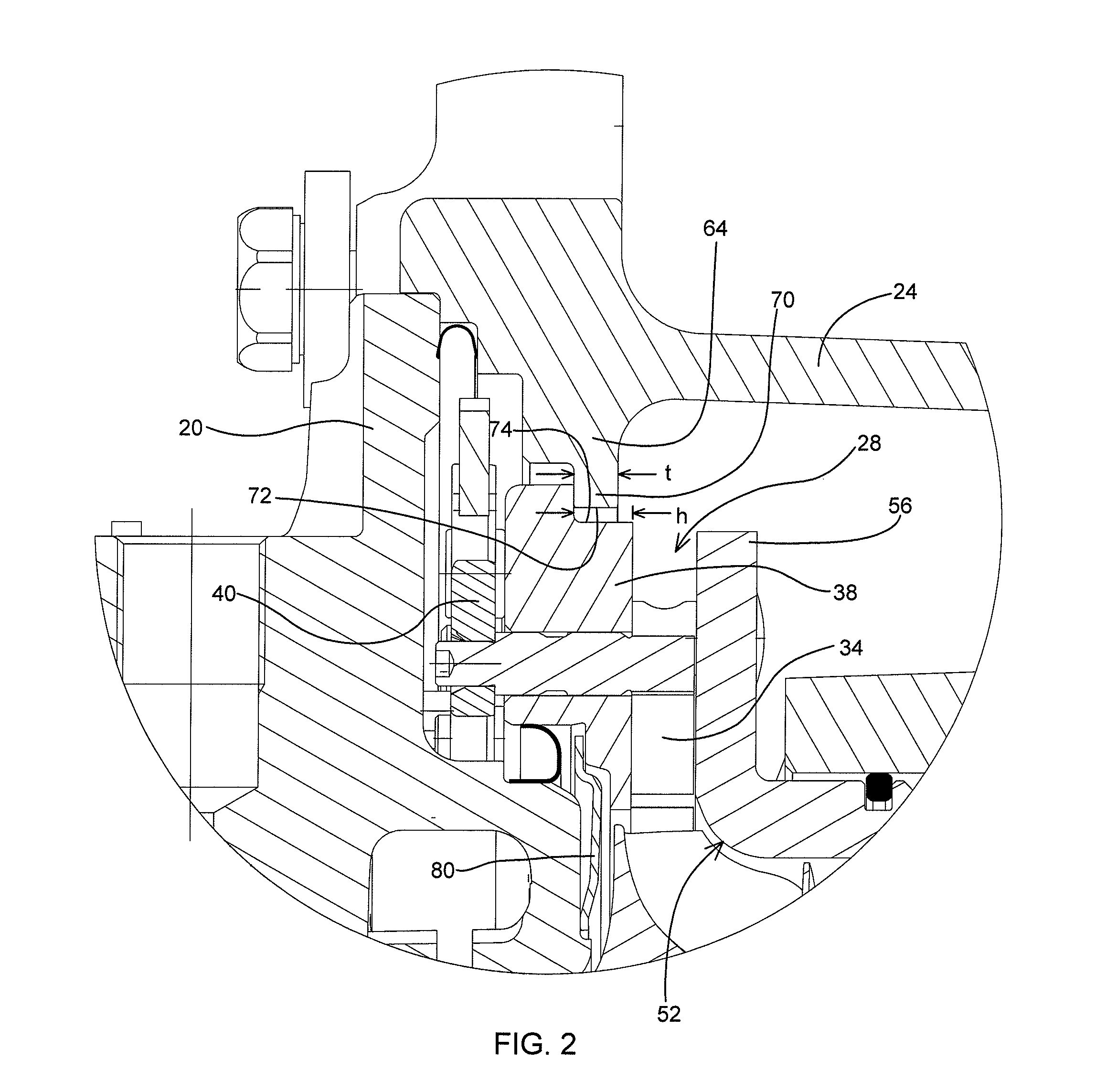

[0016]A turbocharger 10 in accordance with one embodiment of the invention is illustrated in cross-sectional view in FIG. 1. The turbocharger comprises a compressor 12 having a compressor wheel or impeller 14 mounted in a compressor housing 16 on one end of a rotatable shaft 18. The shaft is supported in bearings 19 mounted in a center housing 20 of the turbocharger. The shaft 18 is rotated by a turbine wheel 22 mounted on the other end of the shaft 18 from the compressor wheel, thereby rotatably driving the compr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap