Virtual parallel load module system

a load module and virtual module technology, applied in the field of virtual parallel load module system, can solve the problems of inability to effectively combine multiple prior art devices are not capable of combining some of the load modules into a single virtual load, and lack of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

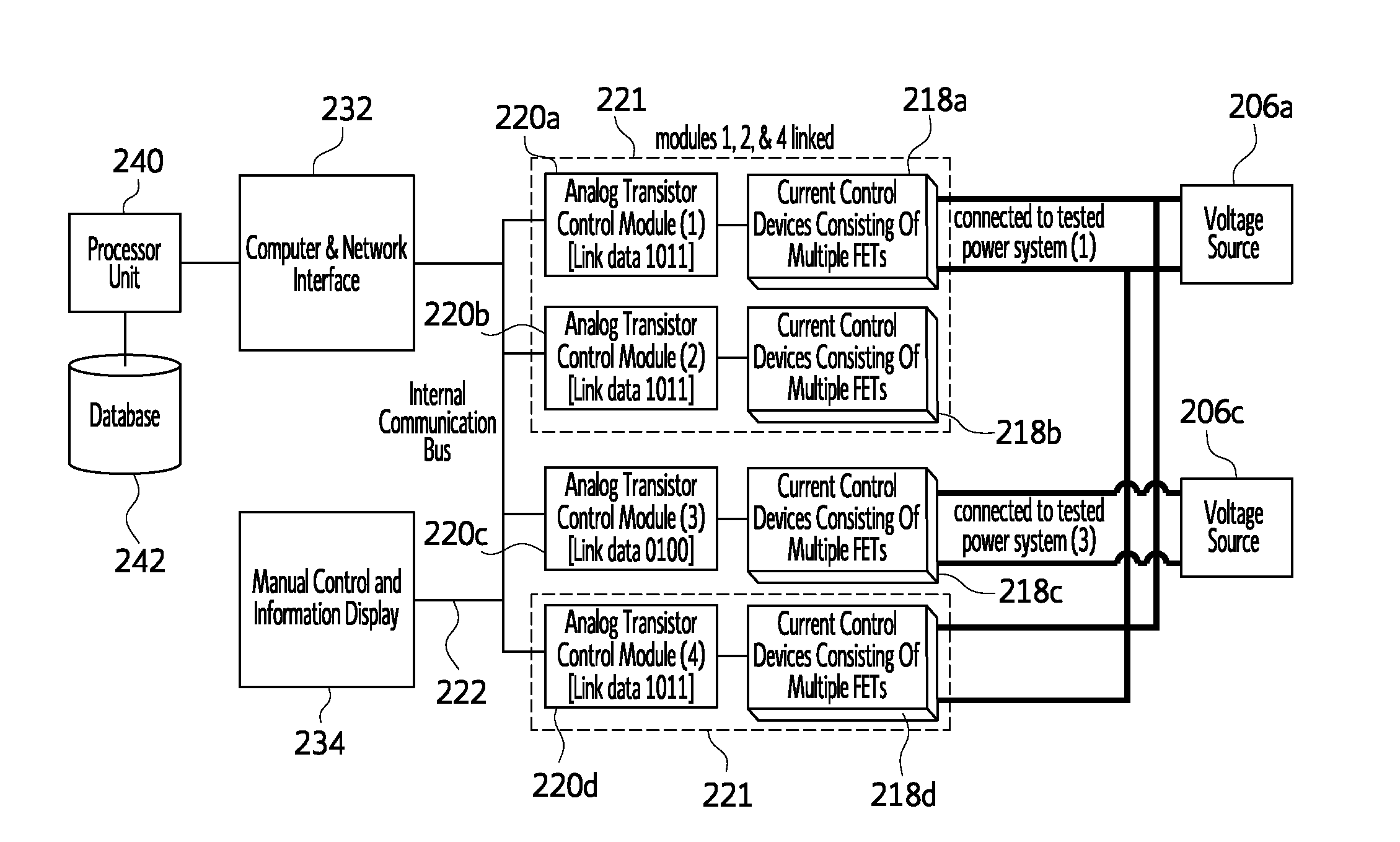

[0021]FIG. 1 shows load systems according to the prior art. In FIG. 1 there is shown a field effect transistor (FET) 2 connected across the terminals 4, 5 of a voltage source 6. The transistor is an electric device where the current through the device is controlled by the voltage applied to a specific terminal. In FIG. 1, the load current through two terminals of the transistor 2 is proportional to the voltage applied to the gate terminal. A current 12 passes between a source terminal 4 and a drain terminal 5. This current 12 may be referred to as the drain current (Idrain). The current 12 is proportional to a voltage applied to gate terminal 10. This voltage may be referred to as the gate voltage (Vgate). Accordingly, the FET can be modeled by the following simple equation:

Idrain=Constant*Vgate [Eq. 1]

[0022]In embodiments of the invention, the gate terminal 10 is connected with an electronic FET controller 8. The controller 8 includes a digital to analog converter that provides the g

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap