Composites and coatings containing multilayer polymer flakes for engineered reflective properties

a technology of reflective properties and composites, applied in anti-reflective coatings, instruments, synthetic resin layered products, etc., can solve the problems of high cost of technology, large number of birds dying, and well-documented crashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

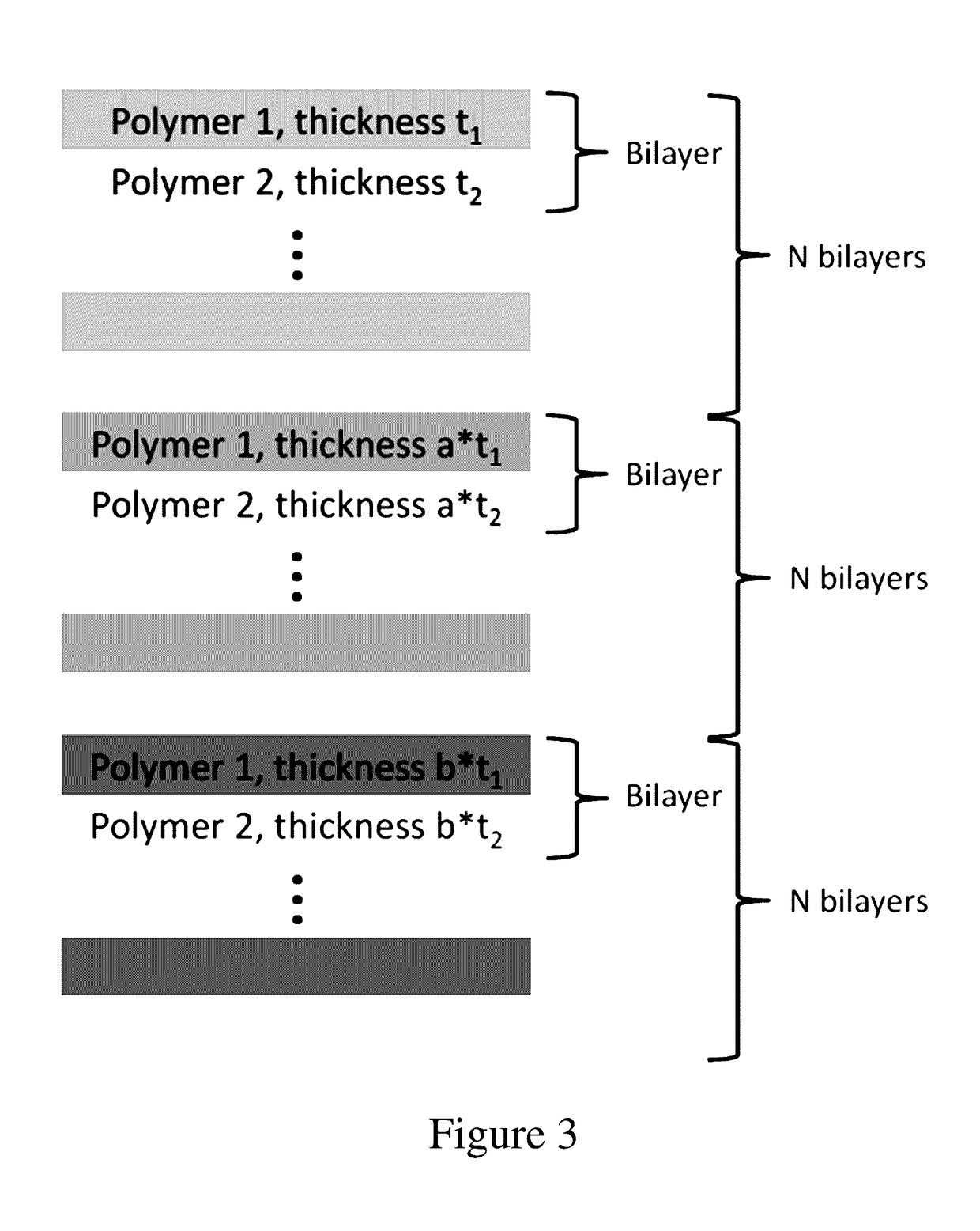

[0048]Stacks of bilayers having PMMA as Polymer 1 and PS as Polymer 2 were fabricated and ground according to the procedure described above. It was desired that the reflectance was maximized at λ1. Each stack comprised only one bilayer thicknesses. The thickness (t1) of the first polymer in the first bilayer was 59 nm, and the thickness (t2) of the second polymer in the first bilayer was 54 nm.

[0049]The stack was ground into flakes via the cryogenic grinding process discussed above. FIG. 5 shows a scanning electron microscope (SEM) image of a cross-section of a flake made by this example, revealing multiple layers. FIG. 6 shows a scanning electron microscope (SEM) image of a collection of flakes of varying size. Flakes were then incorporated via stirring into a polyurethane matrix to form a composite and the composite was painted onto fused quartz wafers. The composite was allowed to dry at room temperature, and the spectral properties were characterized using a spectrophotometer with

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap