Brake pad, disk brake assembly, and vehicle

a technology for brake pads and disc brakes, applied in the field of brake pads, to achieve the effect of increasing the size of the boundary layer and therefore the adhesion between the friction pad and the mounting structure, increasing mechanical strength, and being more robus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Like numbered elements in these figures are either equivalent elements or perform the same function. Elements which have been discussed previously will not necessarily be discussed in later figures if the function is equivalent.

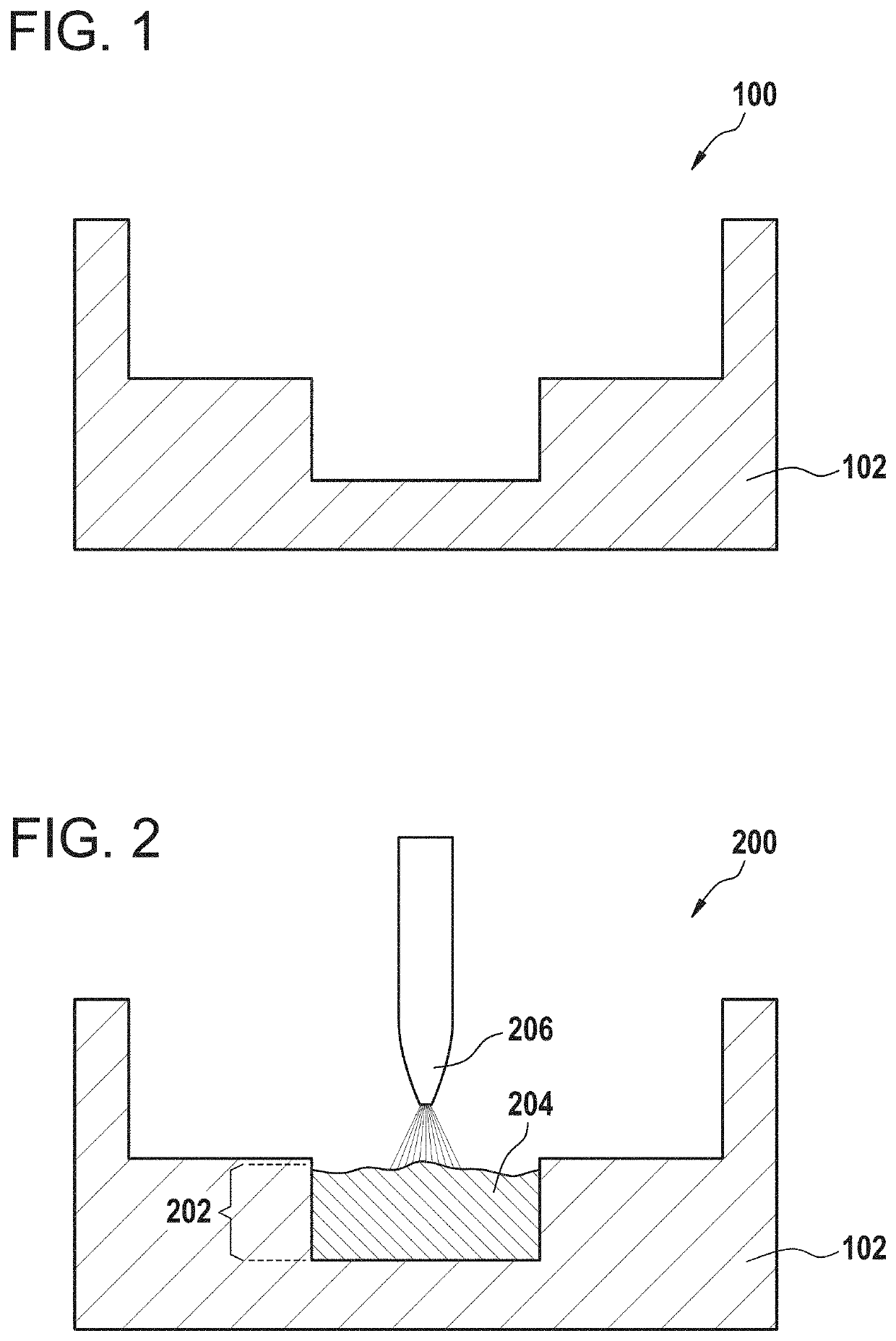

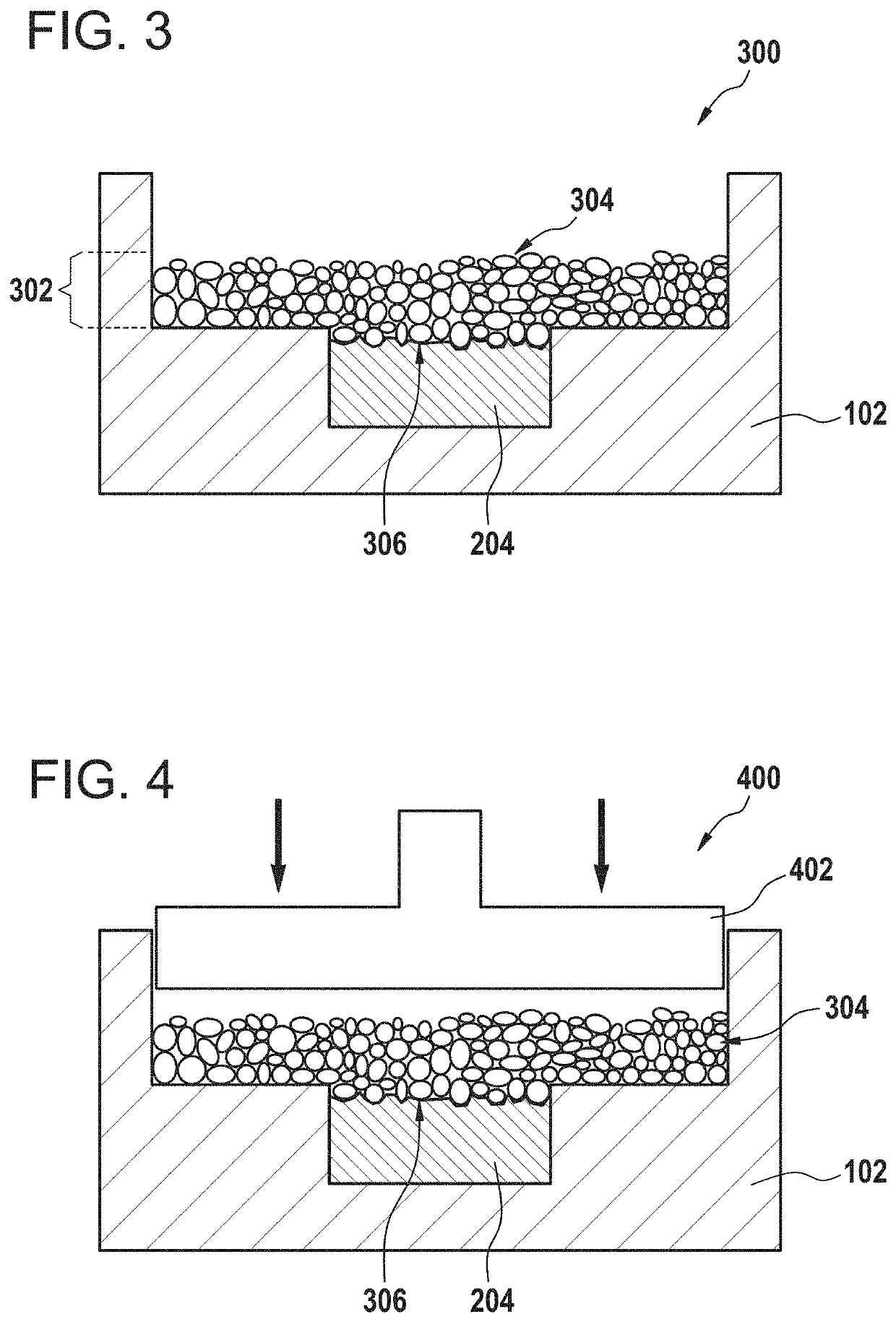

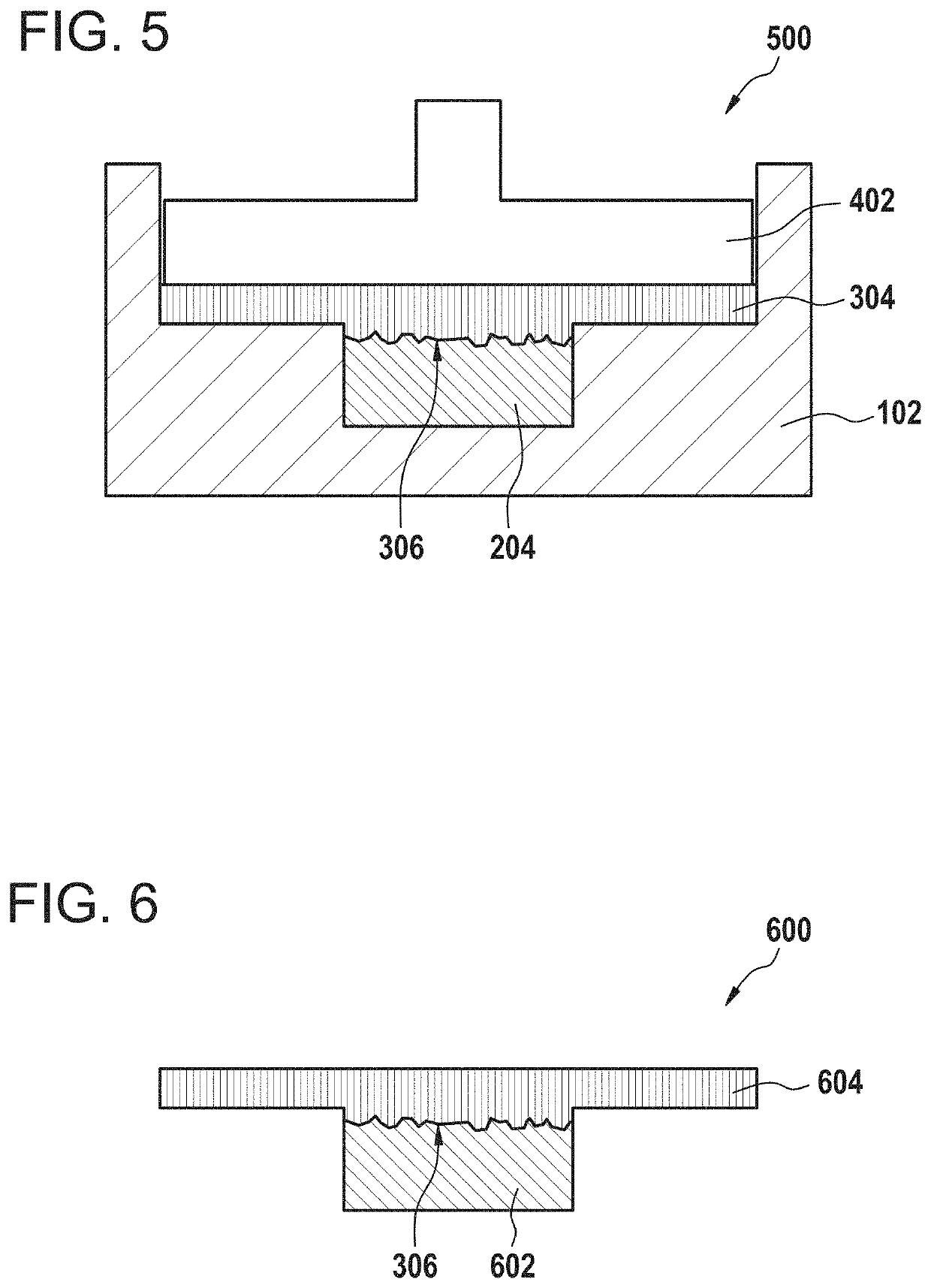

[0053]FIGS. 1-5 illustrate the manufacture of a brake pad using a single press curing step. First in FIG. 1 the step of providing 100 a cure mold 102 is shown. Next in FIG. 2 the step of filling a first portion 202 of the cure mold 102 with particulate friction material 204 is shown. The particulate friction material 204 may for example be provided in either a powder or liquid form depending upon the type or form of the resin used. In this example there is a nozzle 206 which is spraying the particulate friction material 204 into the first portion 202 of the cure mold 100.

[0054]FIG. 3 shows the filling 300 of a second portion 302 of the cure mold 102 with a granulated thermoset plastic 304. After the particulate friction material 204 was filled into the cur

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap