Flexible solar cell

a solar cell and flexible technology, applied in the direction of superimposed coating process, solid-state device, coating, etc., can solve the problems of poor high-humidity durability and poor high-temperature durability of the flexible solar cell containing the organic-inorganic perovskite compound in the photoelectric conversion layer, and achieve excellent high-temperature, high-humidity durability, excellent initial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Anodization of Aluminum Foil

[0092]An aluminum foil (available from UACJ, thickness 100 μm) was anodized with sulfuric acid to form an aluminum oxide film on a surface of the aluminum foil. Thus, a flexible substrate was obtained.

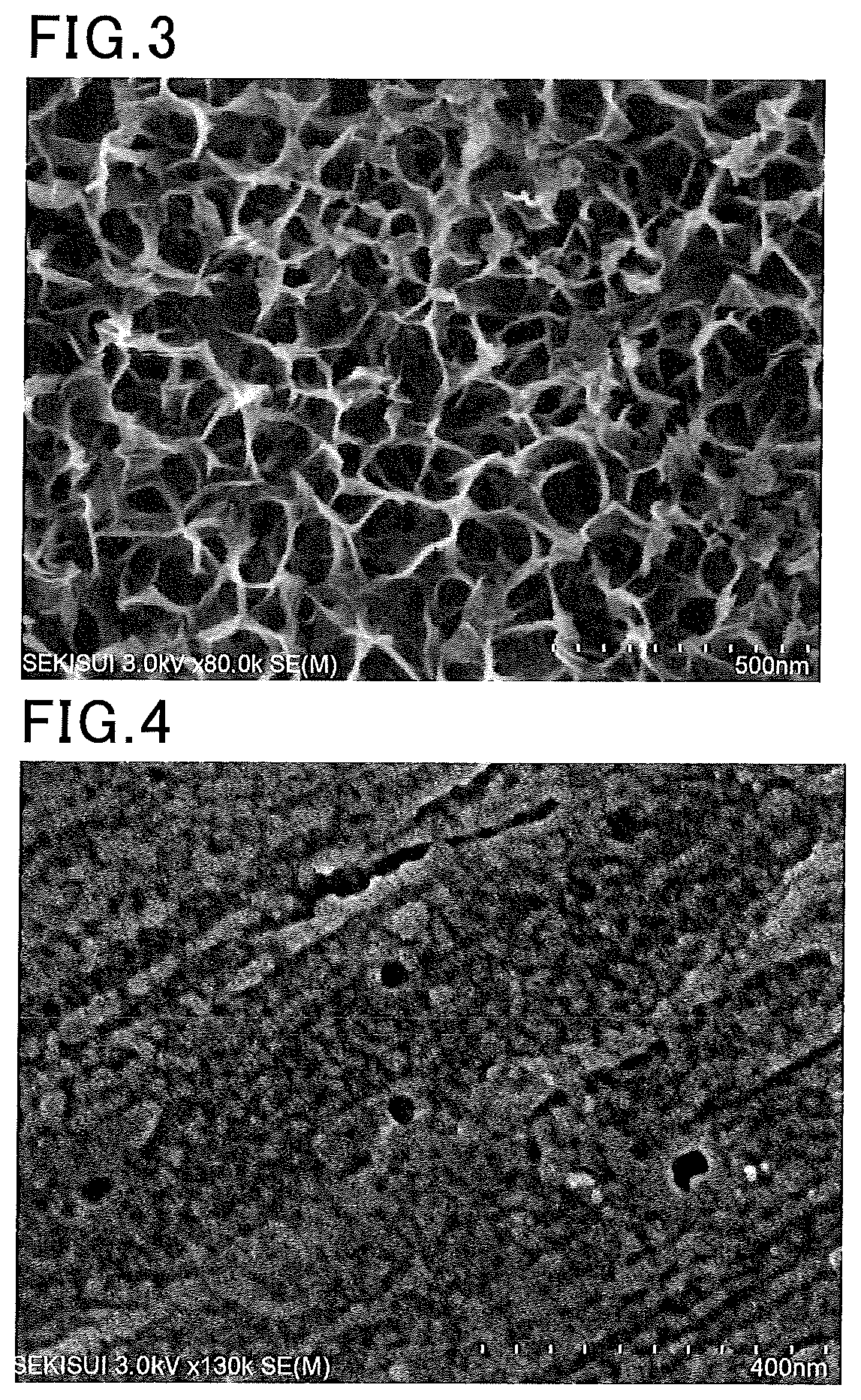

[0093]A cross section of the obtained flexible substrate was observed with an electron microscope (S-4800, available from Hitachi, Ltd.) and the contrast of the obtained photograph was analyzed to measure the thickness of the flexible substrate (the total thickness of the aluminum foil and the aluminum oxide film) and the thickness of the aluminum oxide film. The ratio of the thickness of the aluminum oxide film to the total thickness of the aluminum foil and the aluminum oxide film was calculated from the obtained thicknesses. A surface of the obtained flexible substrate was observed with an electron microscope (S-4800, available from Hitachi, Ltd.) and the crystal structure of the aluminum oxide in the aluminum oxide film was determined to be the boehmite

examples 2 to 9

[0098]A flexible solar cell was obtained as in Example 1 except that the thickness of the aluminum oxide film and the ratio thereof were adjusted as shown in Table 1 by adjusting the thickness of the aluminum foil used and the treatment time or treatment temperature in anodization.

Comparative Examples 1, 2, 8, and 9

[0099]A flexible solar cell was obtained as in Example 1 except that the thickness of the aluminum oxide film and the ratio thereof were adjusted as shown in Table 1 by adjusting the thickness of the aluminum foil used and the treatment time in anodization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap