Oil-in-water emulsion cosmetic composition

a technology of oil-in-water emulsion and cosmetic composition, which is applied in the direction of pharmaceutical active ingredients, make-up, toilet preparations, etc., can solve the problems of difficult dispersal of hydrophobic powder, poor water resistance of cosmetic film obtained by applying cosmetic composition, and accumulation of hydrophobic powder, etc., to achieve excellent water resistance, easy removal, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

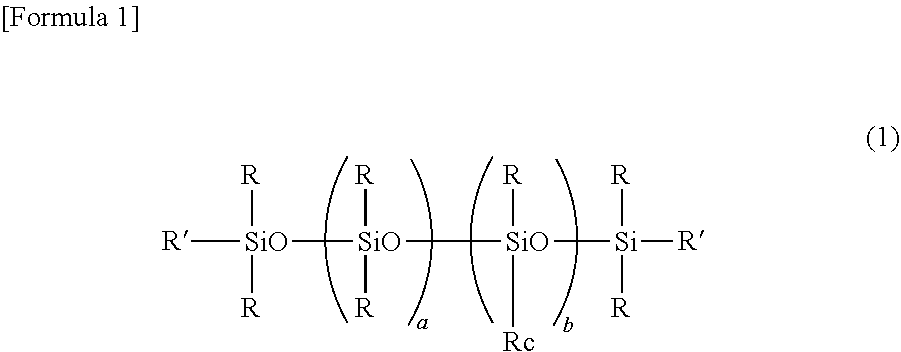

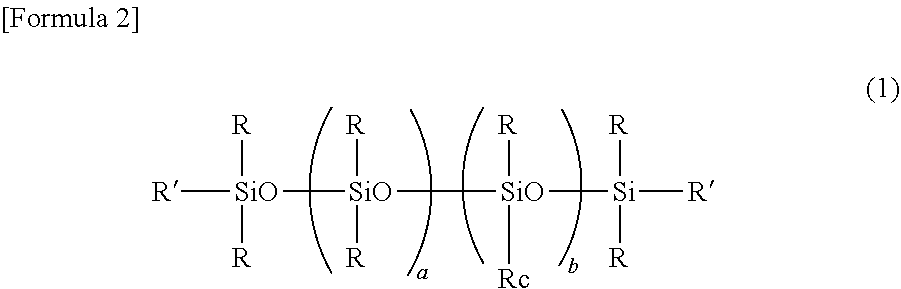

Method used

Image

Examples

synthesis example 1

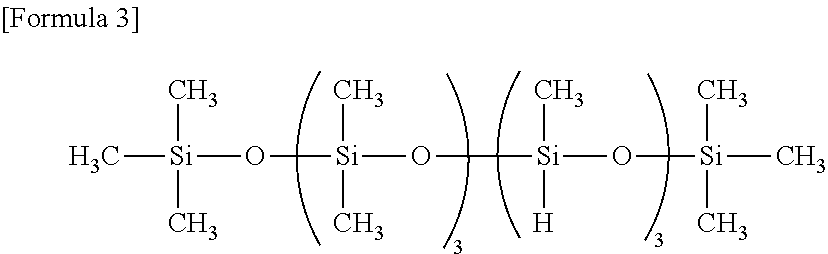

[0130]230.67 g of trimethylsilyl undecylenate and 0.042 g of a platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex were put into a flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and 129.33 g of Si-Hsiloxane expressed by the following general formula was dropped thereinto so as to maintain the range of 70 to 80° C.

[0131]After the completion of dropping, the mixture was aged for 2 hours at 110° C., and then the loss of Si—H bonds was confirmed by the hydrogen generation method. A low boiling point content was distilled off under reduced pressure. Thereafter, 90 g of deionized water was added, and the mixture was aged under reflux for 4 hours for deprotection. Thereafter, the low boiling point content was again removed under reduced pressure to obtain a compound 1. As a result of analysis, it was confirmed that the chemical structure of the compound 1 was expressed by the following chemical formula:

synthesis example 2

[0132]283.39 g of trimethylsilyl undecylenate and 0.054 g of a platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex were put into a flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and 100.61 g of Si-Hsiloxane expressed by the following general formula was dropped thereinto so as to maintain the range of 70 to 80° C.

[0133]After the completion of dropping, the mixture was aged for 2 hours at 110° C., and then the loss of Si—H bonds was confirmed by the hydrogen generation method. A low boiling point content was distilled off under reduced pressure. Thereafter, 96 g of deionized water was added, and the mixture was aged under reflux for 4 hours for deprotection. Thereafter, the low boiling point content was again removed under reduced pressure to obtain a compound 2. As a result of analysis, it was confirmed that the chemical structure of the compound 2 was expressed by the following chemical formula:

synthesis example 3

[0134]159.00 g of trimethylsilyl undecylenate and 0.035 g of a platinum-1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex were put into a flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and 141.00 g of Si-Hsiloxane expressed by the following general formula was dropped thereinto so as to maintain the range of 70 to 80° C.

[0135]After the completion of dropping, the mixture was aged for 2 hours at 110° C., and then the loss of Si—H bonds was confirmed by the hydrogen generation method. A low boiling point content was distilled off under reduced pressure. Thereafter, 150 g of deionized water was added, aged at reflux for 4 hours, and deprotection was performed. Thereafter, the low boiling point content was again removed under reduced pressure to obtain a compound 3. As a result of analysis, it was confirmed that the chemical structure of the compound 3 was expressed by the following chemical formula:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap