Relief module and device for unloading bulk material

a relief module and bulk material technology, applied in the direction of loading/unloading, packaging, large containers, etc., can solve the problems of large amount of dust being launched into the environment, undesired overload to the assembly, etc., and achieve the effect of reducing the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

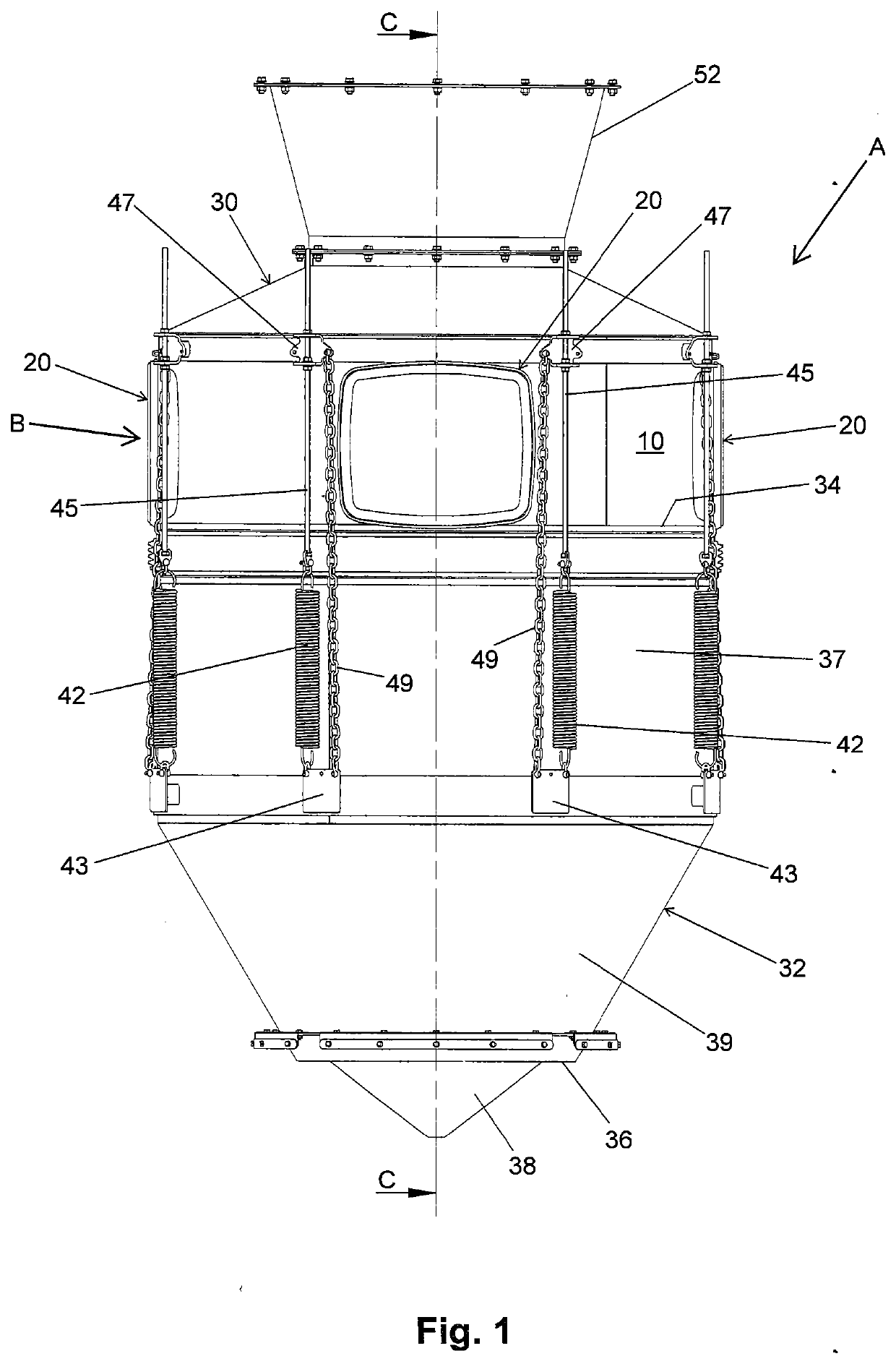

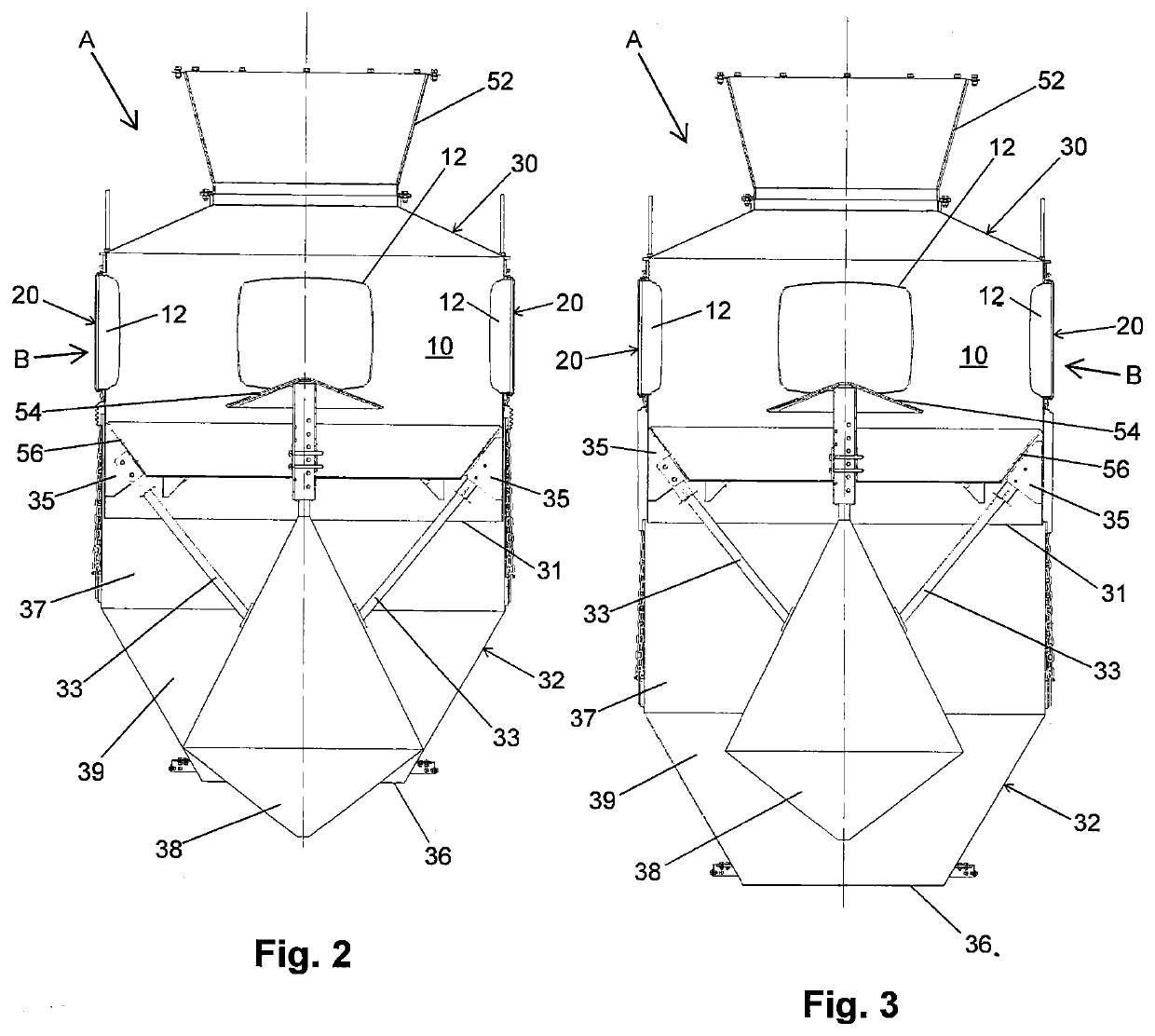

[0022]The invention proposes a relief module and a bulk material discharge device comprising a relief module. FIGS. 1 to 3 show an embodiment of a discharge device (A) comprising an incorporation of a relief module (B). The discharge device (A) receives the bulk material from a feeding system, preferably an enclosed feeding system and discharges the bulk material to a destination. It is noted that the relief module (B) proposed by the invention can be used in association with different types of discharge devices, without being limited to the embodiment of the shown discharge device (A).

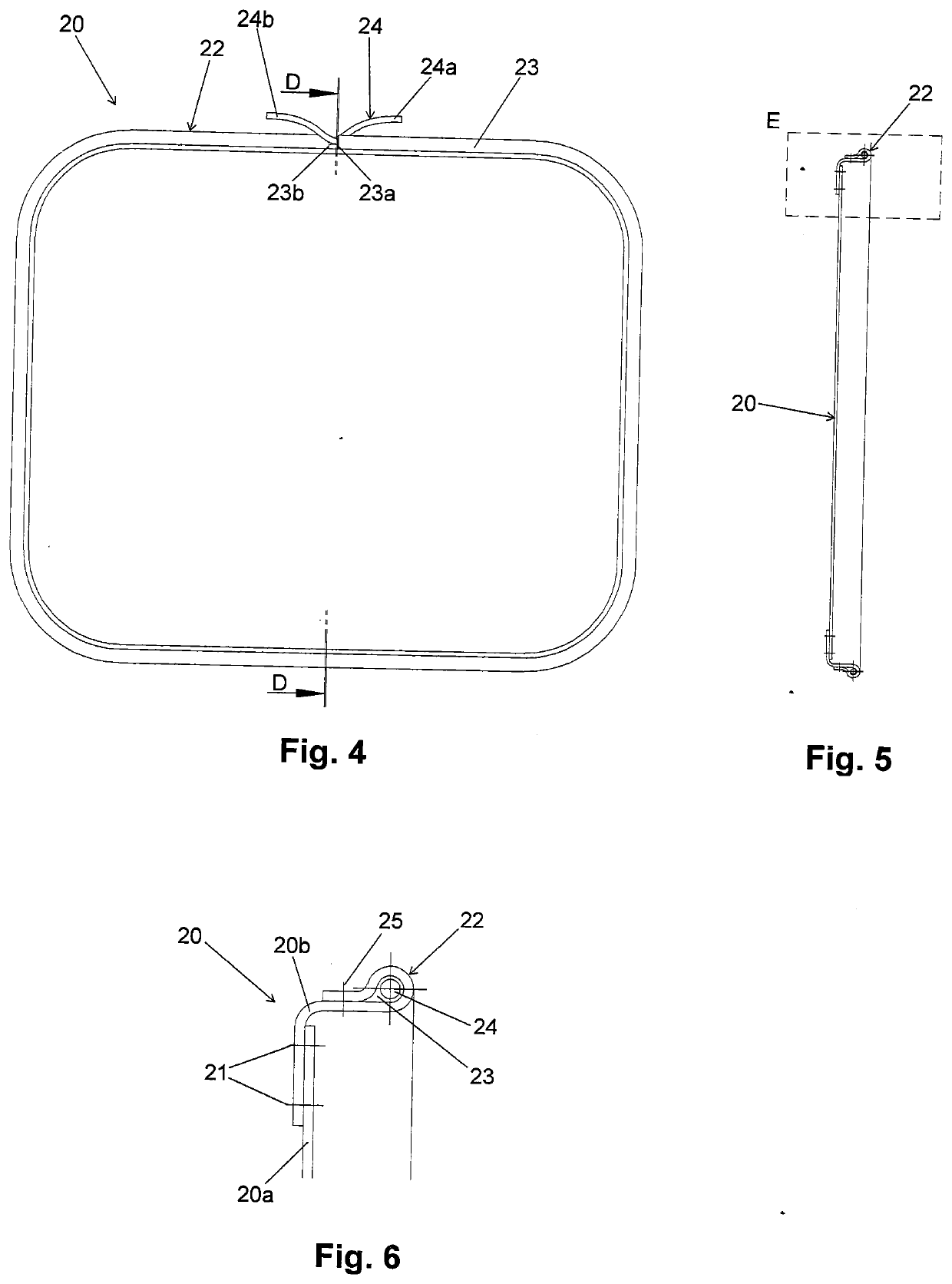

[0023]According to the invention, the relief module (B) comprises a tubular body (10) intended for the passage of the bulk material, at least a lateral opening (12) in the tubular body (10), a window (20) to cover the respective lateral opening (12), the window (20) operating in a closed position preventing the bulk material from exiting through the lateral opening (12) or in an open position allowing th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap