Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Crazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

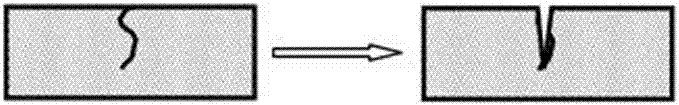

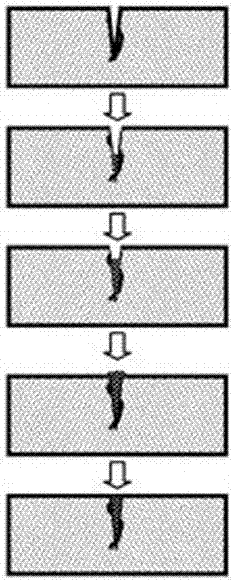

Crazing is the phenomenon that produces a network of fine cracks on the surface of a material, for example in a glaze layer. Crazing frequently precedes fracture in some glassy thermoplastic polymers. As it only takes place under tensile stress, the plane of the crazing corresponds to the stress direction. The effect is visibly distinguishable from other types of fine cracking because the crazing region has different refractive indices from surrounding material. Crazing occurs in regions of high hydrostatic tension, or in regions of very localized yielding, which leads to the formation of interpenetrating microvoids and small fibrils. If an applied tensile load is sufficient, these bridges elongate and break, causing the microvoids to grow and coalesce; as microvoids coalesce, cracks begin to form.

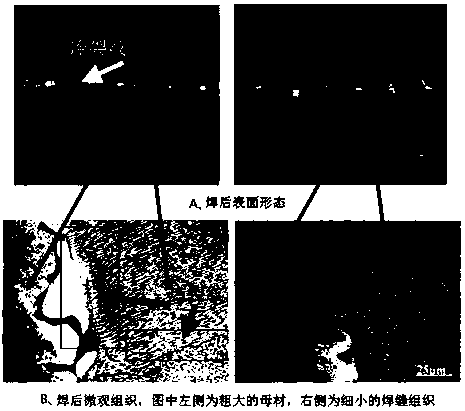

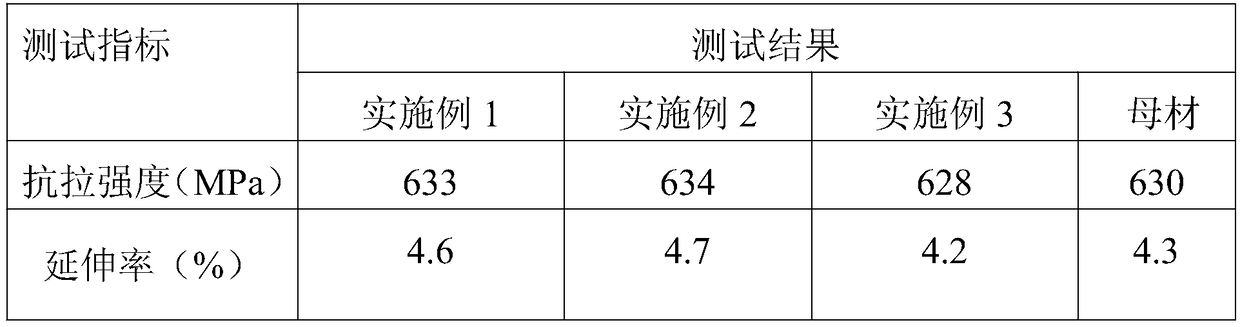

Laser welding method of CoCrCuFeNi high-entropy alloy

ActiveCN108747006AHigh strengthImprove plasticityLaser beam welding apparatusCrazingHigh entropy alloys

Owner:GUIZHOU INST OF TECH

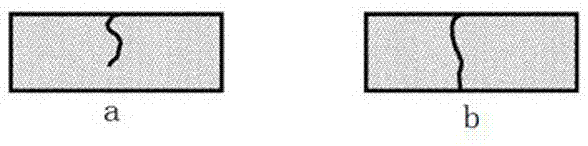

Restorative method for ceramic cores with crack defects

Owner:DONGFANG TURBINE CO LTD

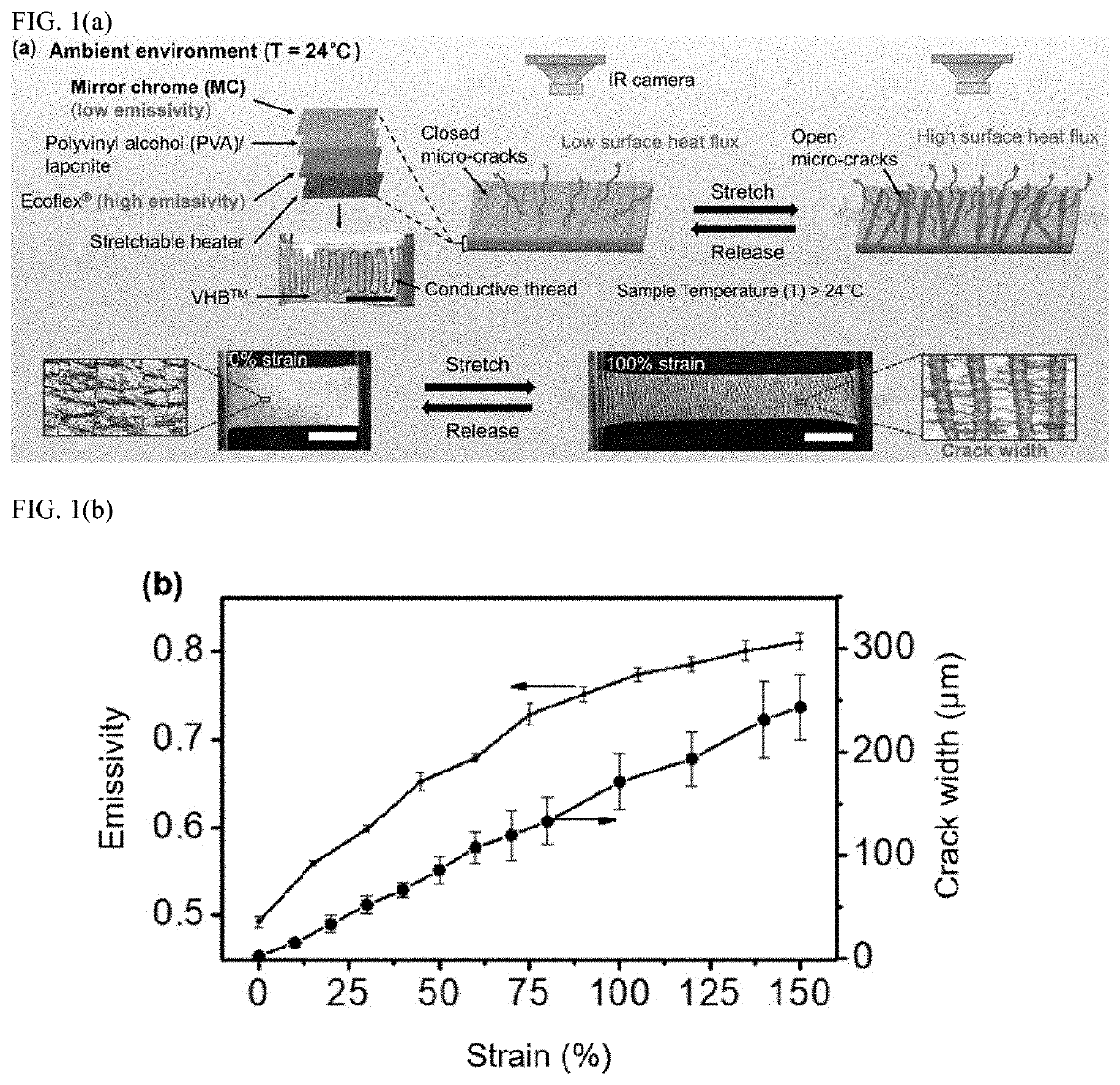

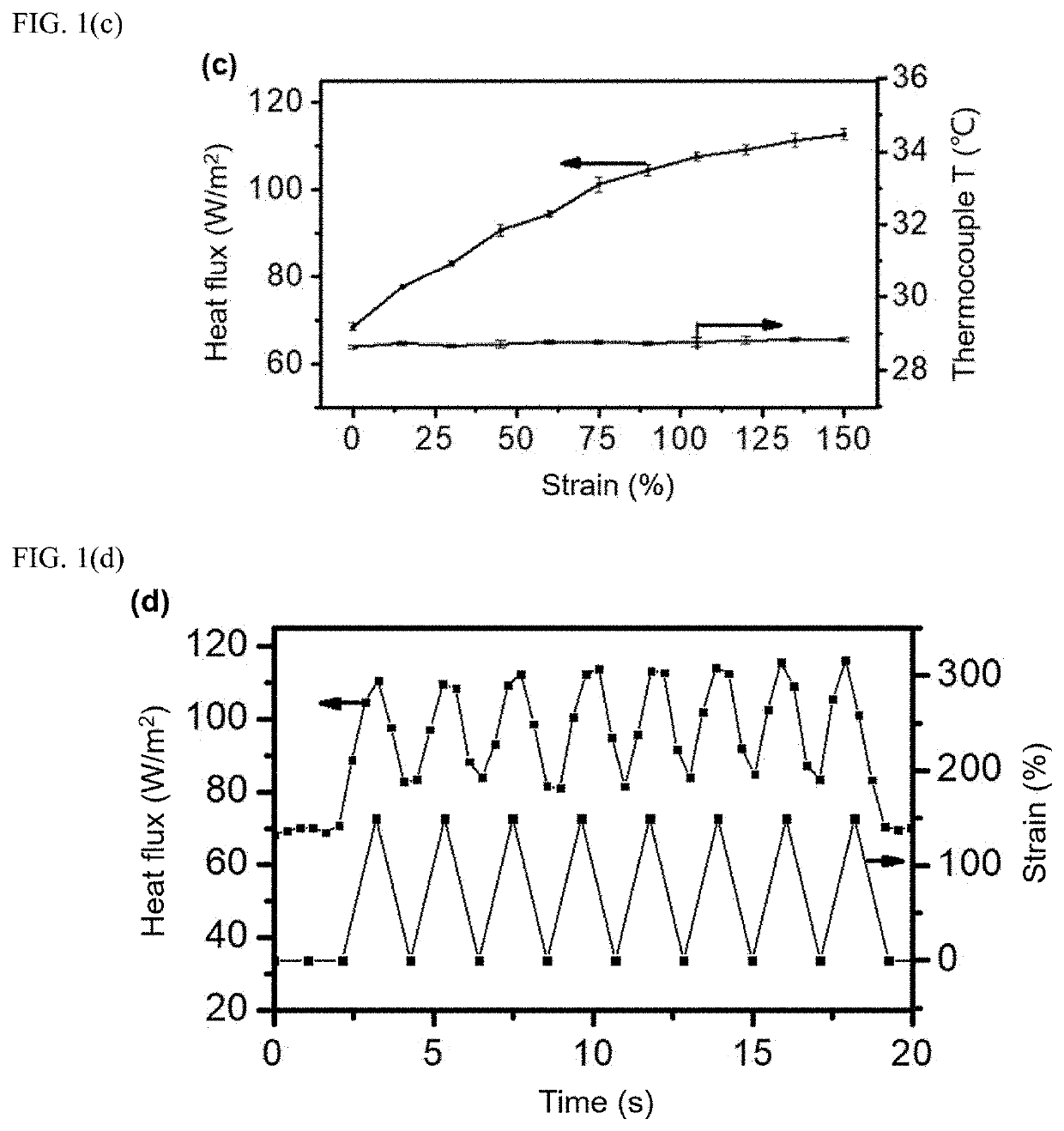

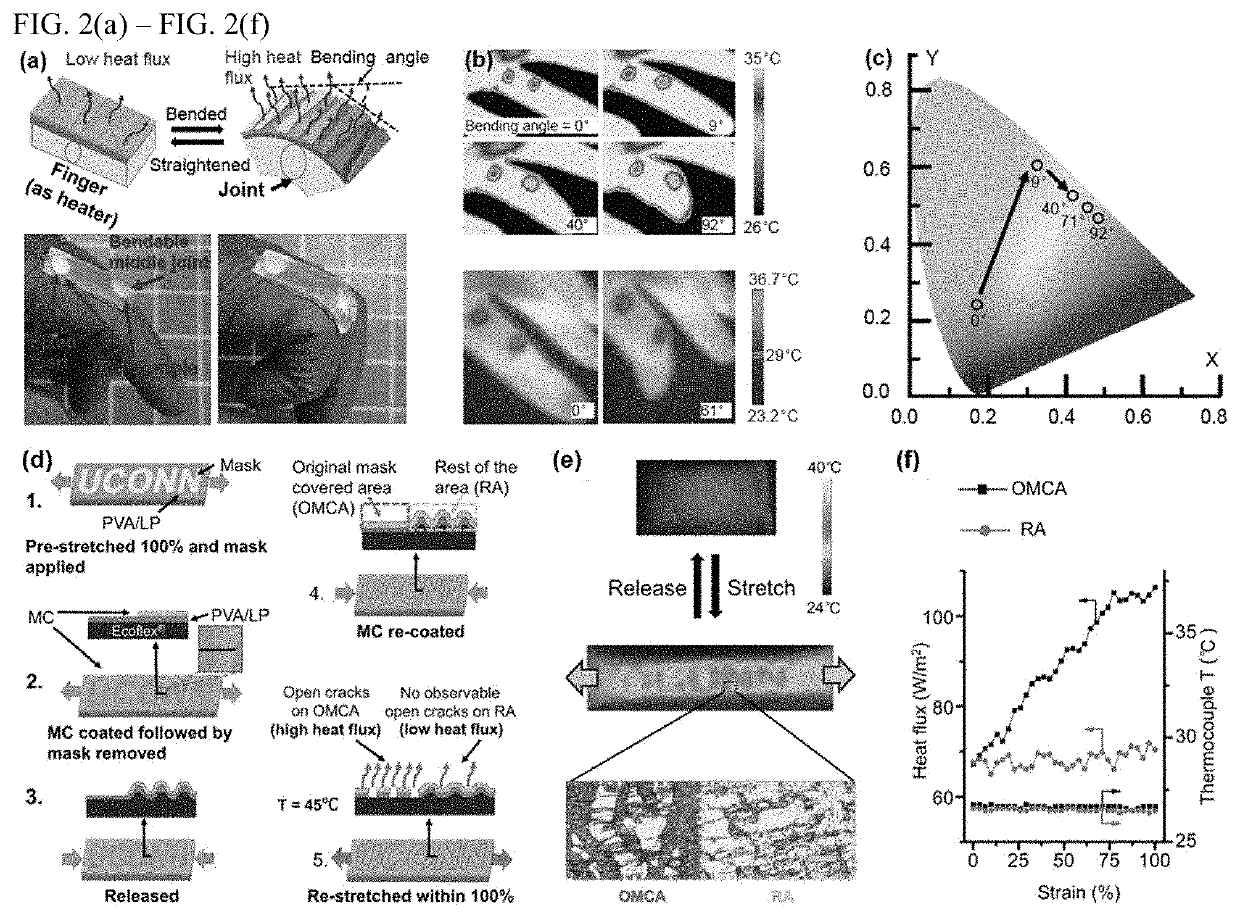

Stretchable thermal radiation modulation system via mechanically tunable surface emissivity

PendingUS20210213718A1Low emissivityLamination ancillary operationsSynthetic resin layered productsPhysicsCrazing

Owner:UNIV OF CONNECTICUT

Reproducible repair method for micro cracks of Nixing pottery

Owner:QINZHOU UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap