Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Glass container" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Container glass is a type of glass for the production of glass containers, such as bottles, jars, drinkware, and bowls. Container glass stands in contrast to flat glass (used for windows, glass doors, transparent walls, windshields) and glass fiber (used for thermal insulation, in fiberglass composites, and optical communication).

Structure improved glass mould

The invention relates to a structure improved glass mould. The glass mould includes a pair of bottle half-dies, each bottle half-die has a bottle half-die cavity and a bottle bottom die cooperating cavity under the bottle half-die cavity, first axial exhaust holes are arranged in the semi-arc direction of the bottle half-die, and extend downward from the top of the bottle half-die to an air outletring groove, which is arranged on the outer wall of the bottle half-die, second axial exhaust holes are arranged in the semi-arc direction of the bottle half-die and on the inner sides of the first axial exhaust holes, the second axial exhaust holes correspond to the neck and shoulder area of the bottle half-die, and the bottle half-die cavity and the second axial exhaust holes are communicated by radial exhaust holes. The glass mould is characterized in that: an edge accelerated cooling mechanism is formed around the semi-arc direction of the bottle half-die corresponding to a position abovethe air outlet ring groove on the outer wall of the bottle half-die, switches off the lower ends of the first axial exhaust holes, and enables communication of the lower ends of the first axial exhaust holes with itself. The structure improved glass mould can improve the manufacturing efficiency of glass containers with rectangular cross-sections and guarantee the quality of glass containers.

Owner:CHANGSHU JIANHUA MOLD TECH

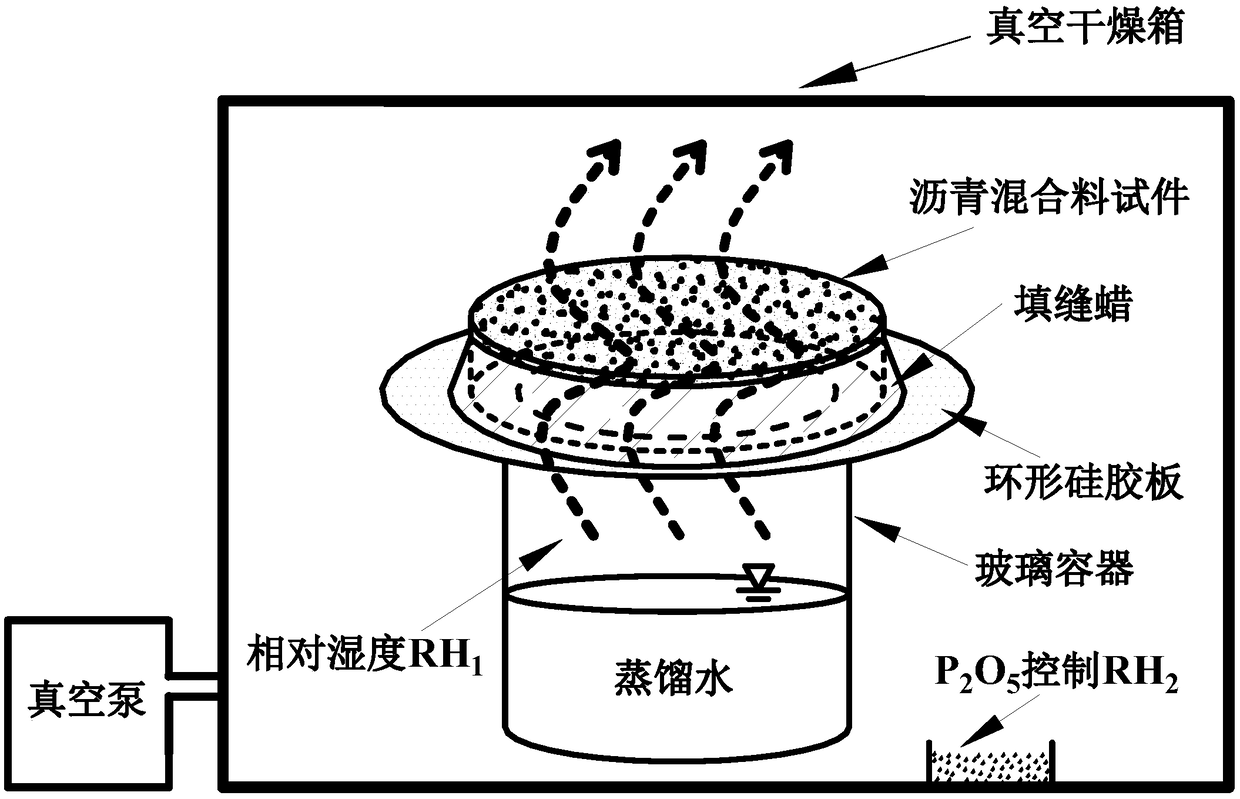

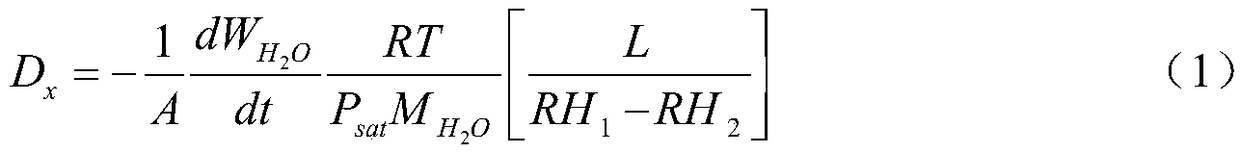

A method for detecting the penetration type water vapor diffusion coefficient of a large-thickness low-porosity asphalt mixture

ActiveCN108776084ARealize humidity gradient driveIncrease humiditySurface/boundary effectPorosityWater vapor

Owner:WUHAN UNIV OF TECH

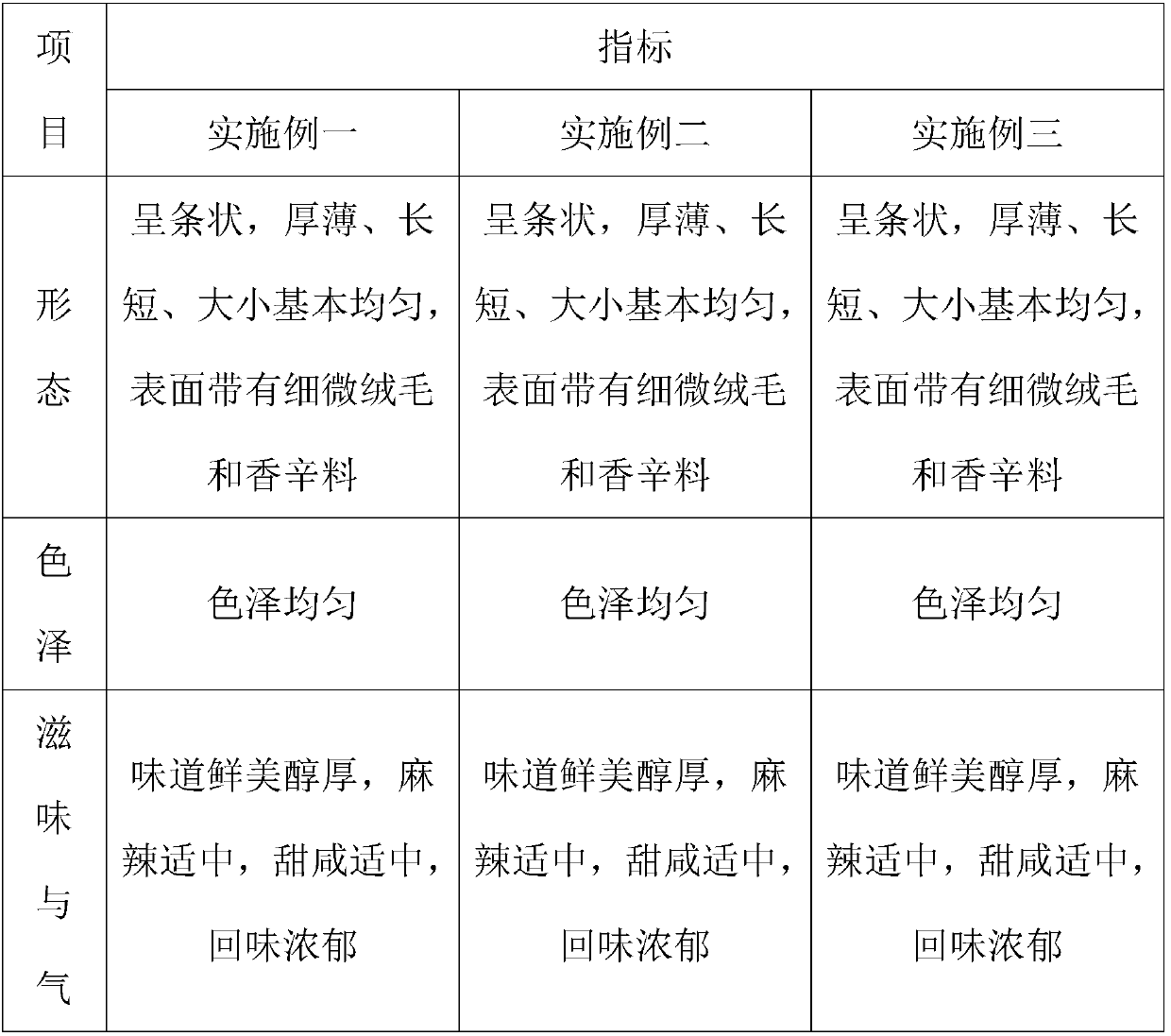

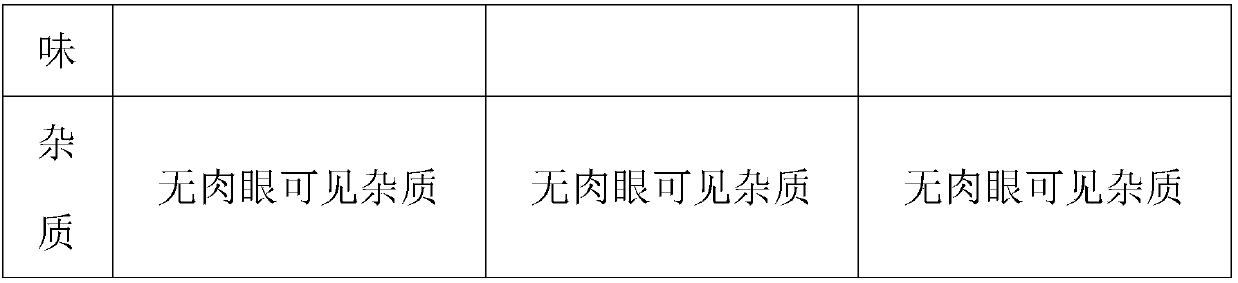

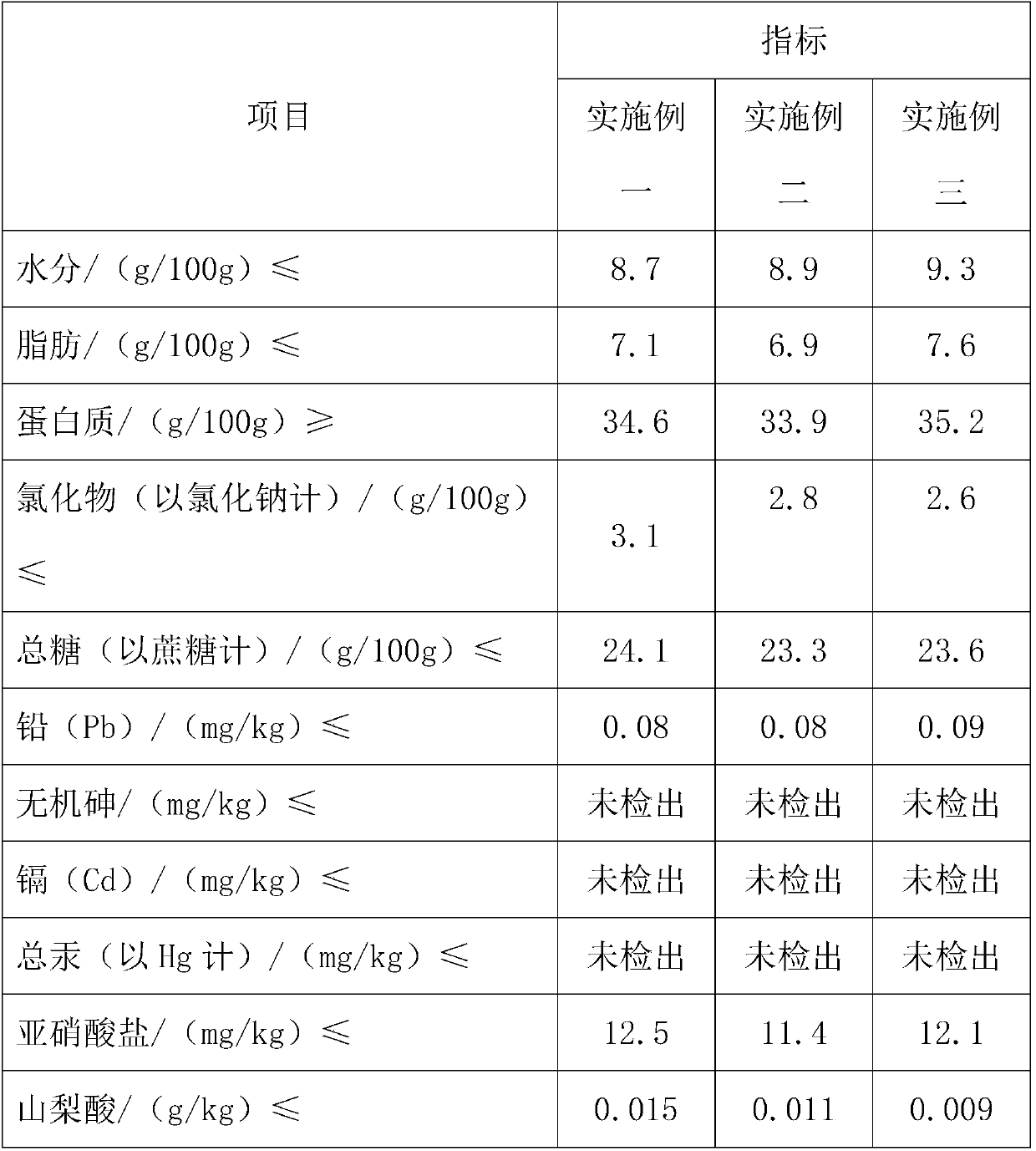

Hand-shredded beef jerky

PendingCN110403138AMellow and deliciousModerately spicyMeat/fish preservation by heatingClimate change adaptationMicrowave ovenRoom temperature

Owner:福建全家福食品有限公司

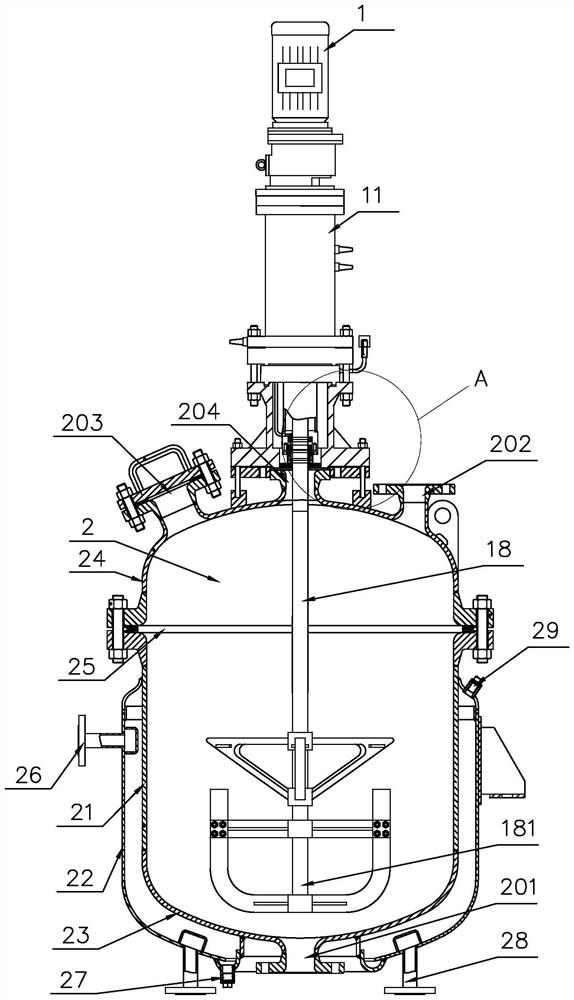

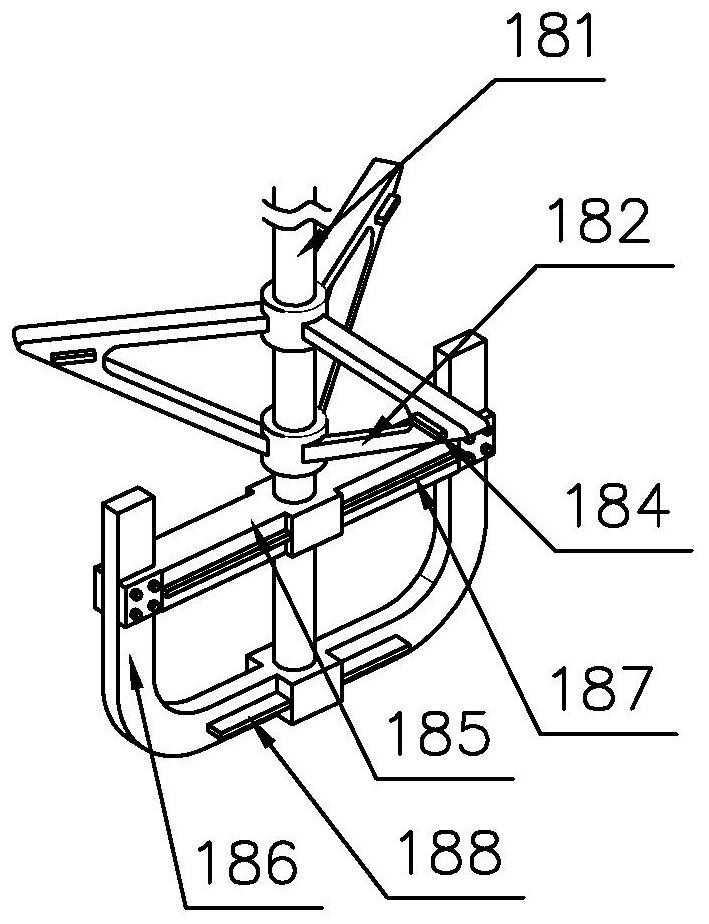

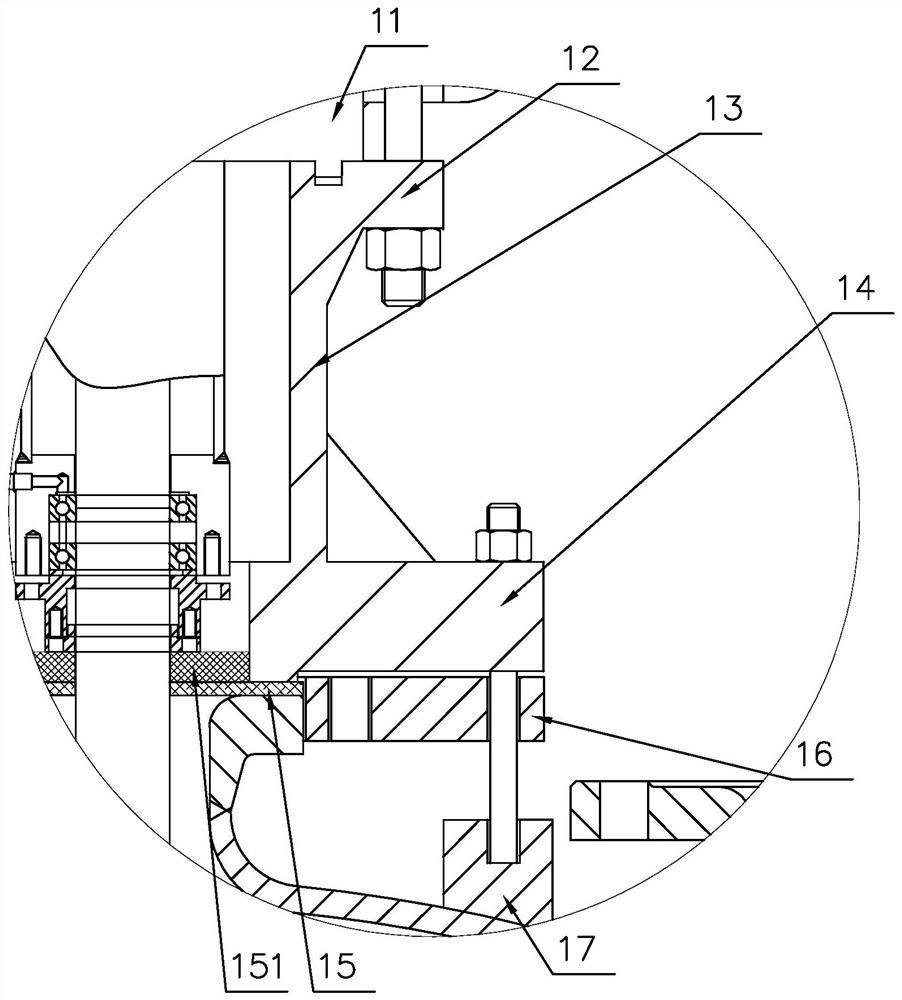

Glass-lined container with magnetic stirring function

PendingCN113694853AMixersChemical/physical/physico-chemical stationary reactorsMagnetic stirrerGlass container

Owner:临沂宏业化工设备有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap