Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

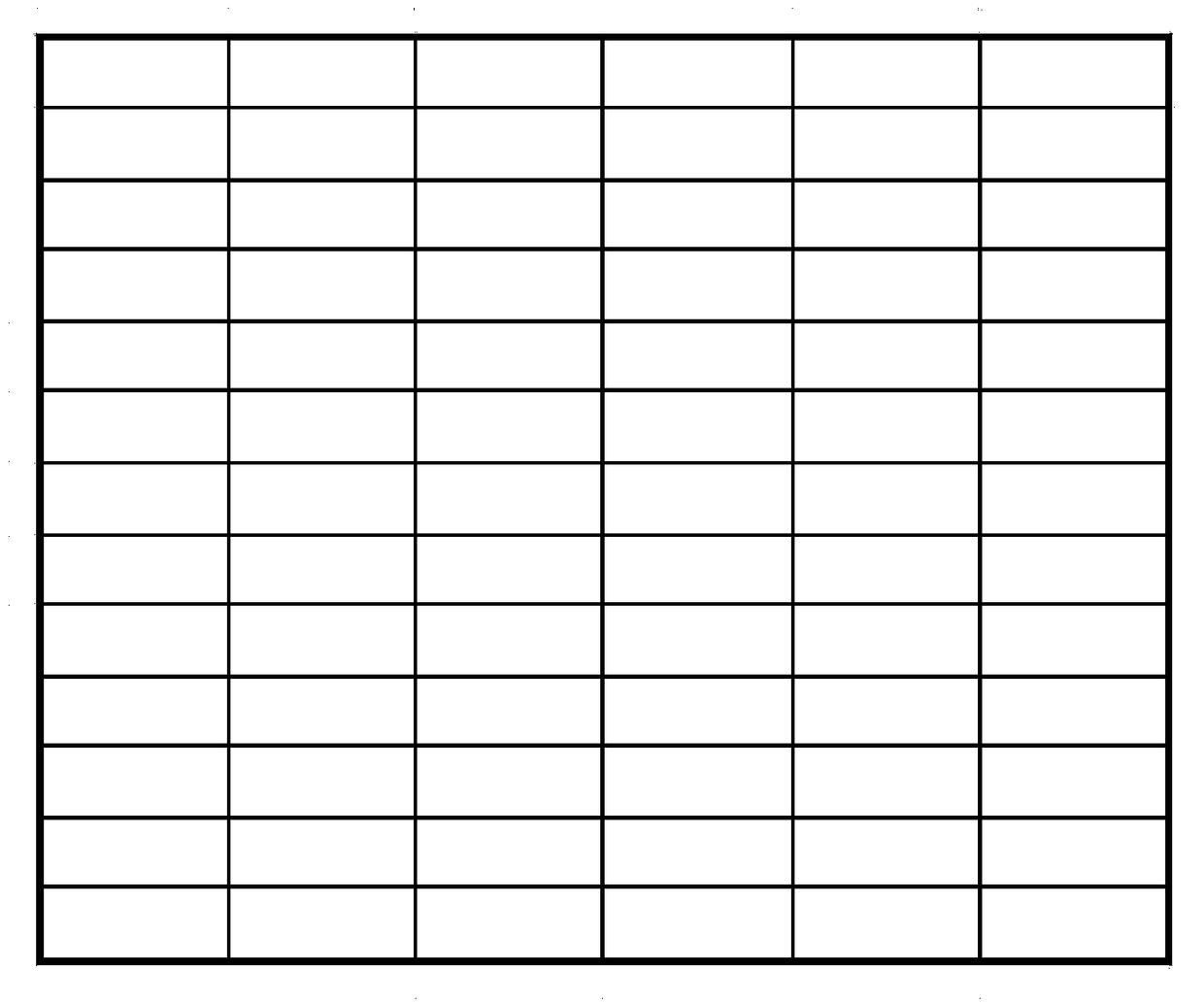

12 results about "Gray level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

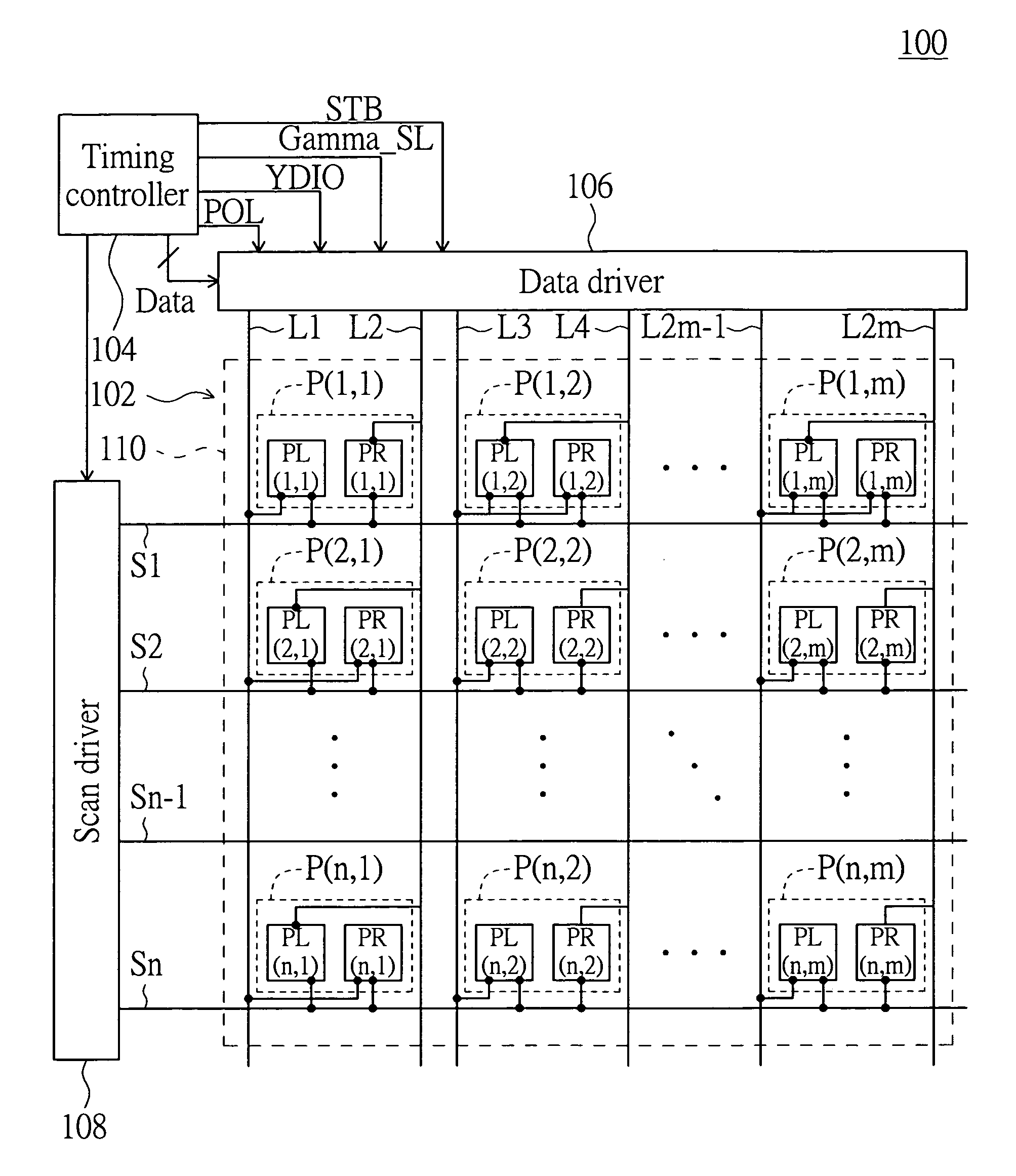

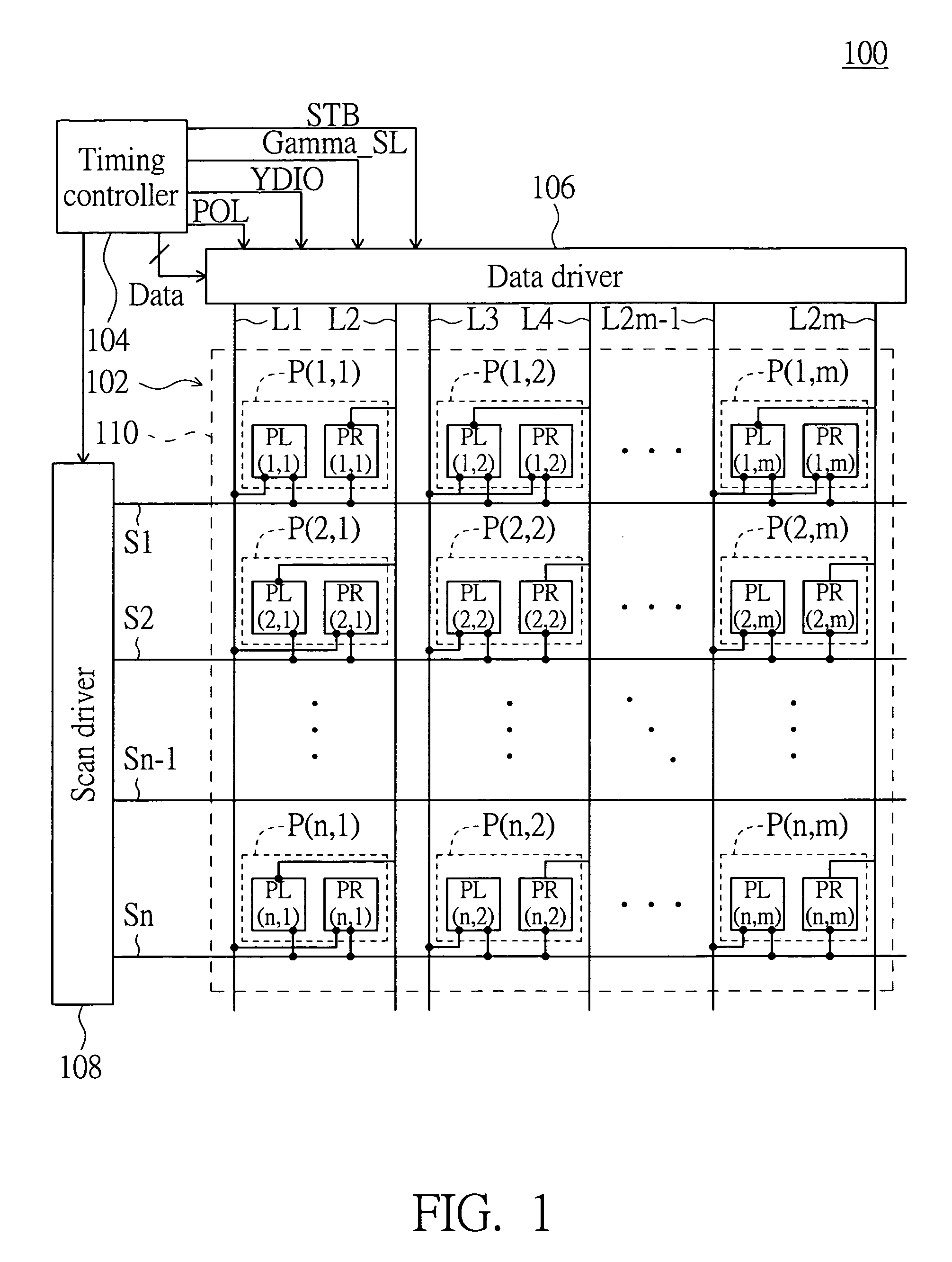

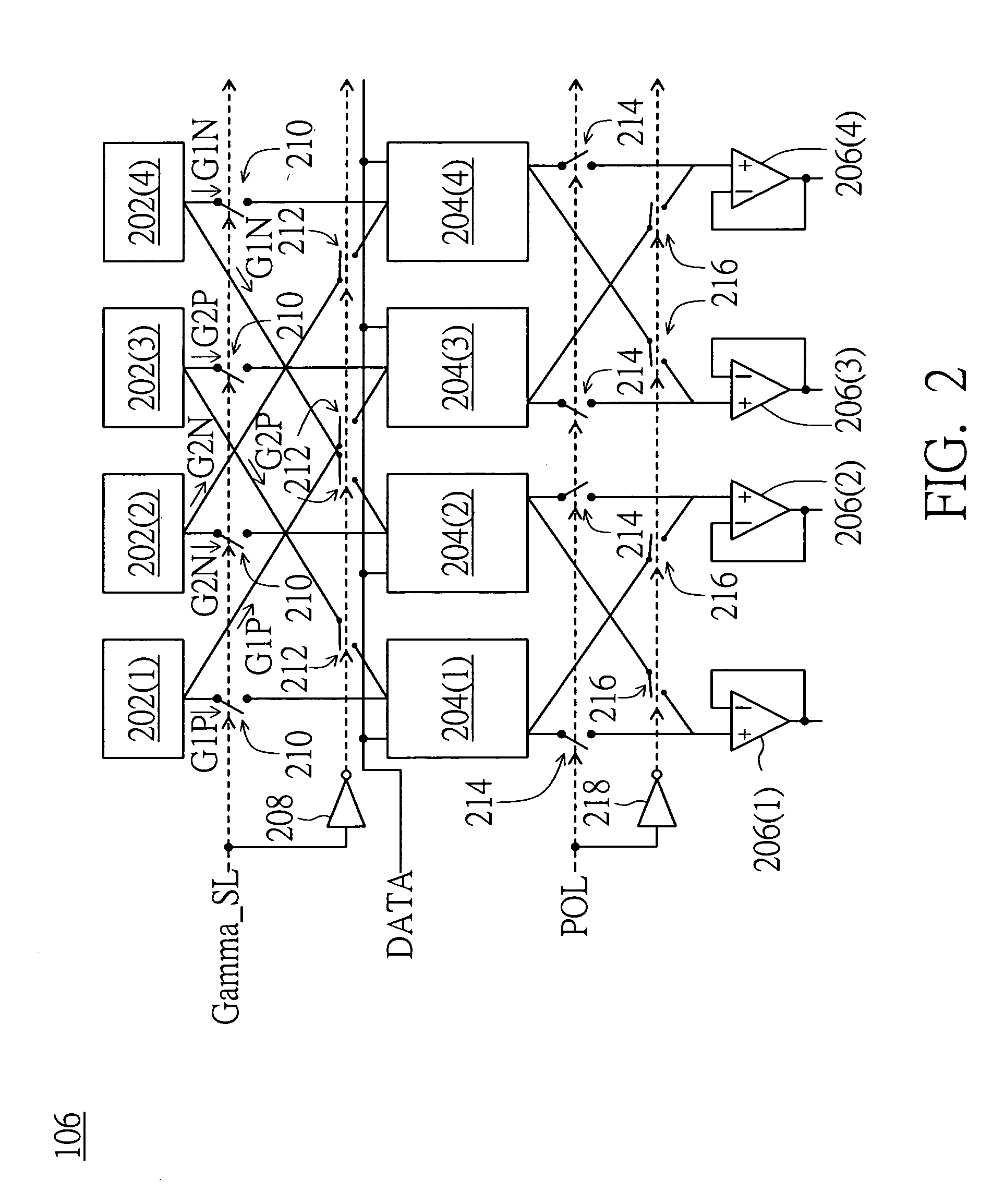

Data driver using a gamma selecting signal, a flat panel display with the same and a driving method therefor

ActiveUS20090160879A1Cathode-ray tube indicatorsInput/output processes for data processingFlat panel displayGray level

Owner:AU OPTRONICS CORP

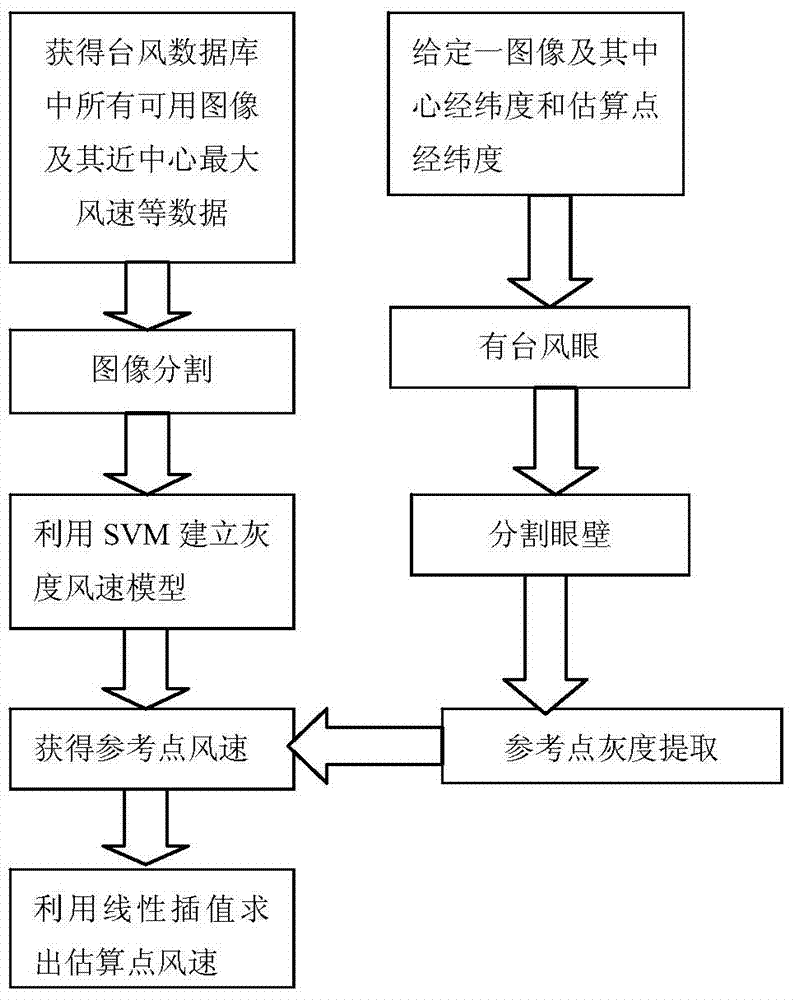

Method for eyed typhoon two-dimensional surface wind field inversion on basis of SVM and PDE

Owner:ZHEJIANG NORMAL UNIVERSITY

(k,n) threshold based user-friendly visual secret sharing method

ActiveCN105404817AImprove the range of image applicationsIncrease contrastDigital data protectionGray levelHistogram equalization

The invention discloses a (k,n) threshold based user-friendly visual secret sharing method and mainly solves the problems of low security and contrast in the prior art. The method is implemented by the steps of 1, performing (k,n) random grid processing on a binary secret image S to obtain n basic shared images of random grids; 2, performing block segmentation on an input gray cover image by using histogram equalization to obtain a gray level equivalent to the gray level of each small image block; 3, performing halftone processing on the cover image subjected to the block segmentation, and according to a generated dithering matrix, obtaining a shared cover image after the halftone processing; and 4, performing block segmentation on the generated basic shared images and cover image, performing combination according to a stacking ratio of a constant value delta, and performing block segmentation and combination to generate a meaningful final shared image. According to the method, the attack of attackers can be prevented, the meaningful final shared image can be generated, and the application range of visual secret sharing can be extended.

Owner:XIDIAN UNIV

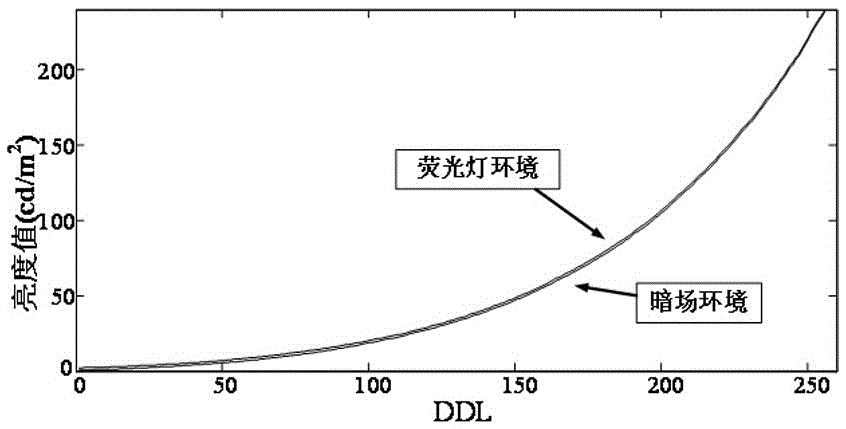

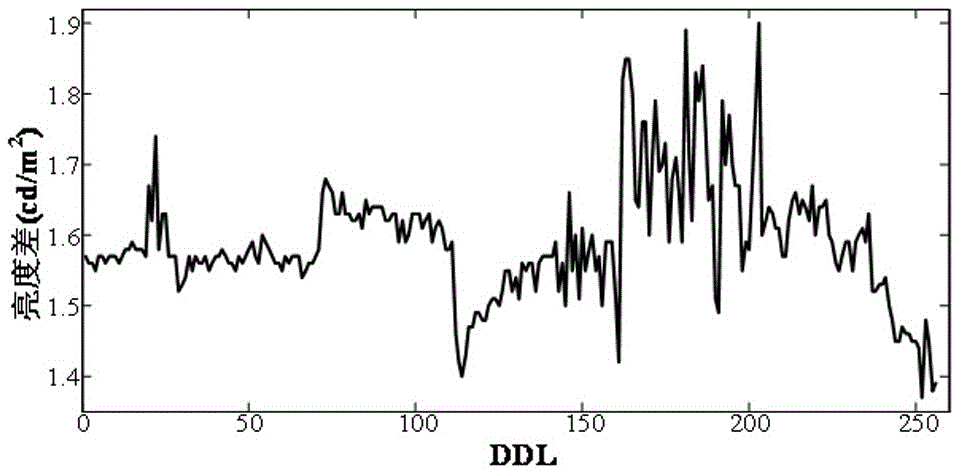

Gray-scale brightness curve correction system and method

InactiveCN105788566AAccurate identificationRealize receiving measurementsCathode-ray tube indicatorsDICOMGray level

Owner:NANJING JUSHA DISPLAY TECH

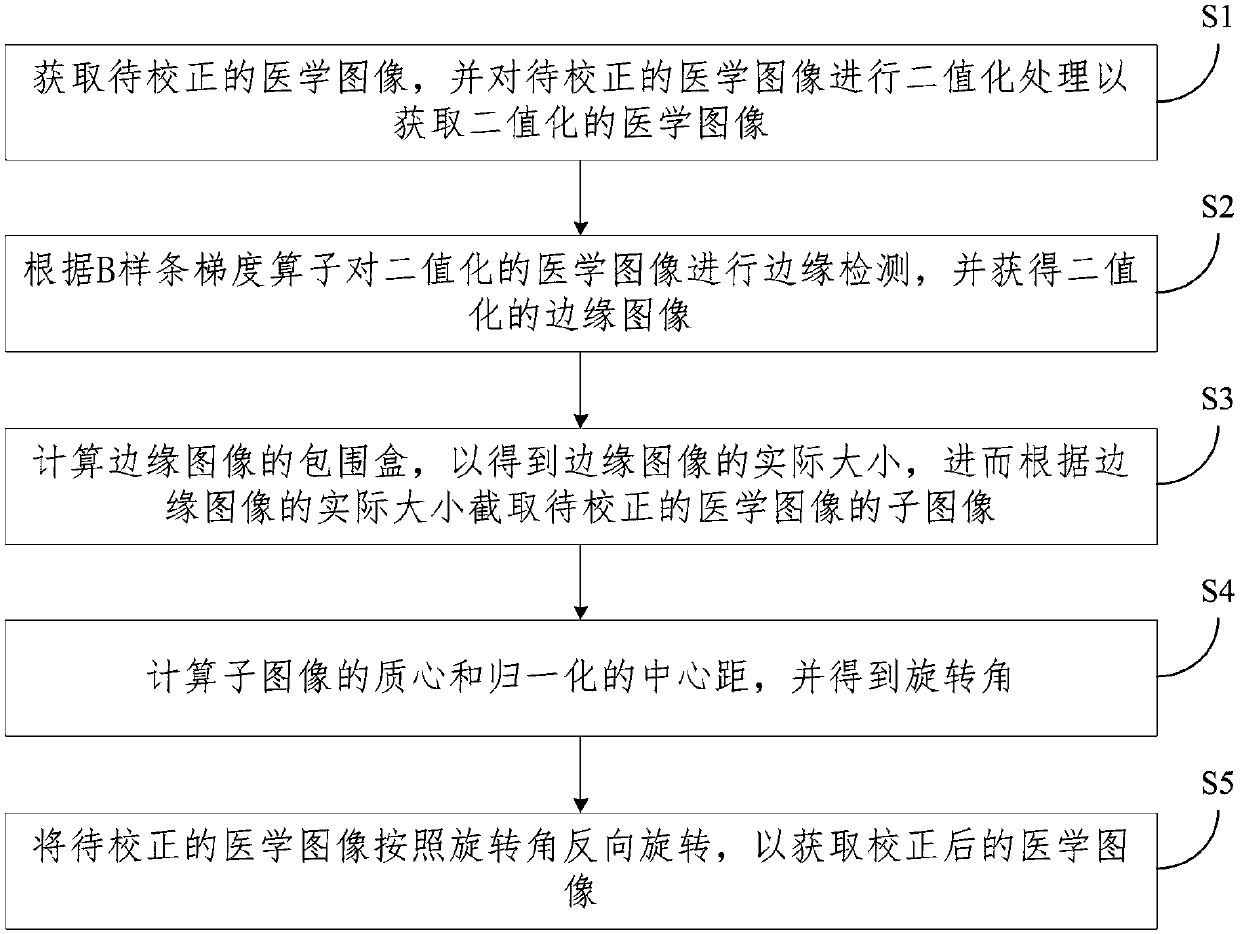

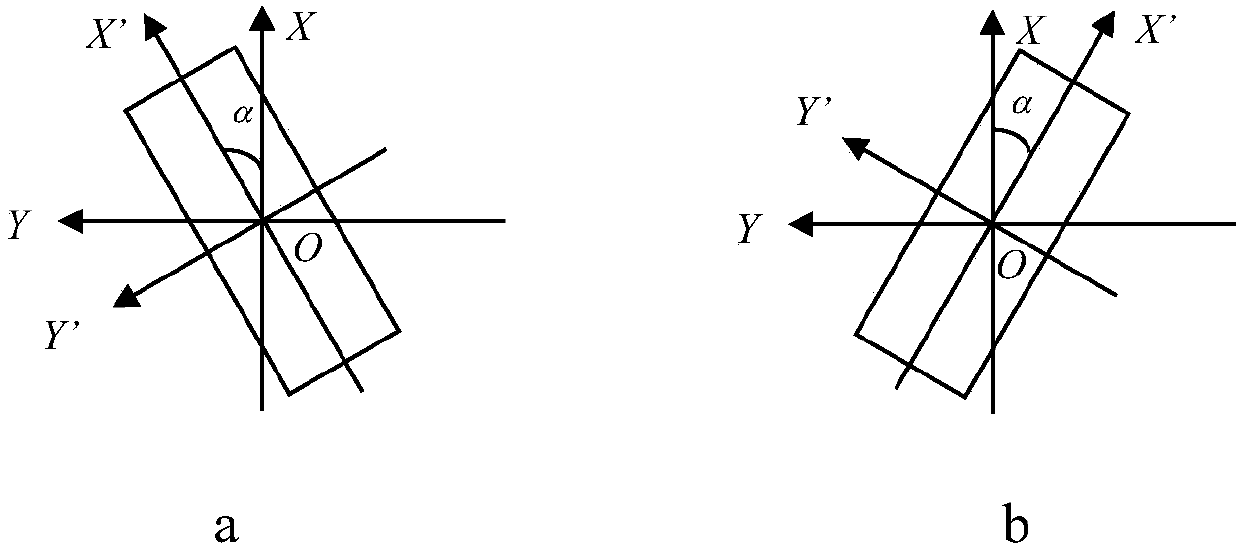

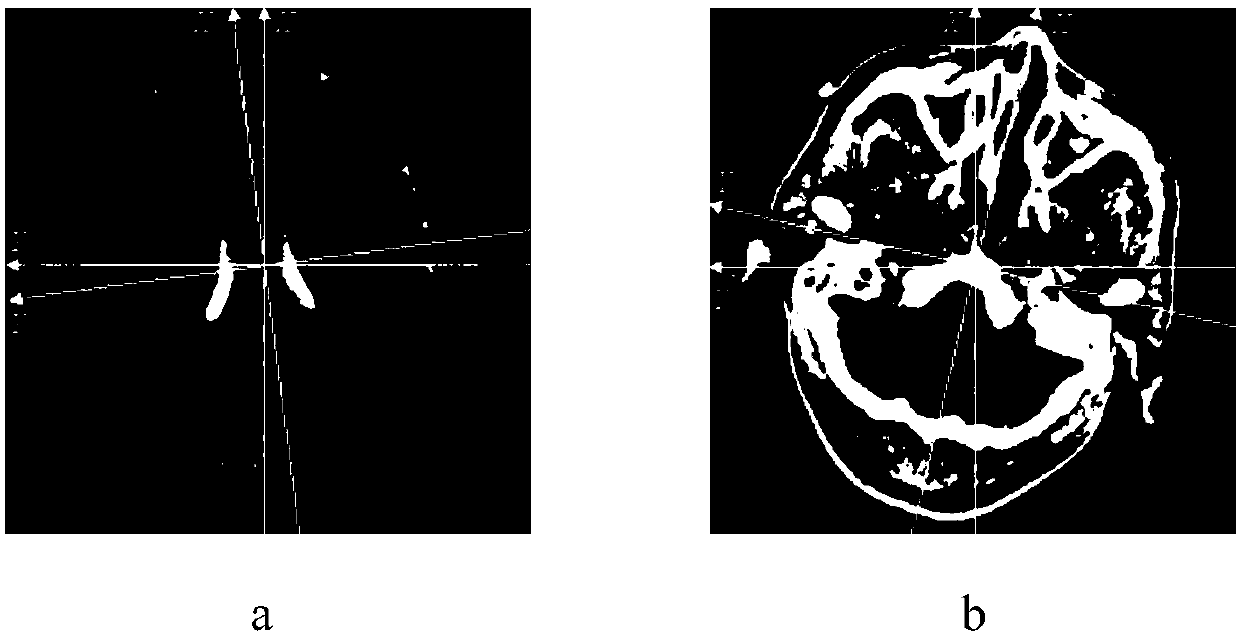

Medical image inclination correction method based on B spline

Owner:HUNAN UNIV OF ARTS & SCI

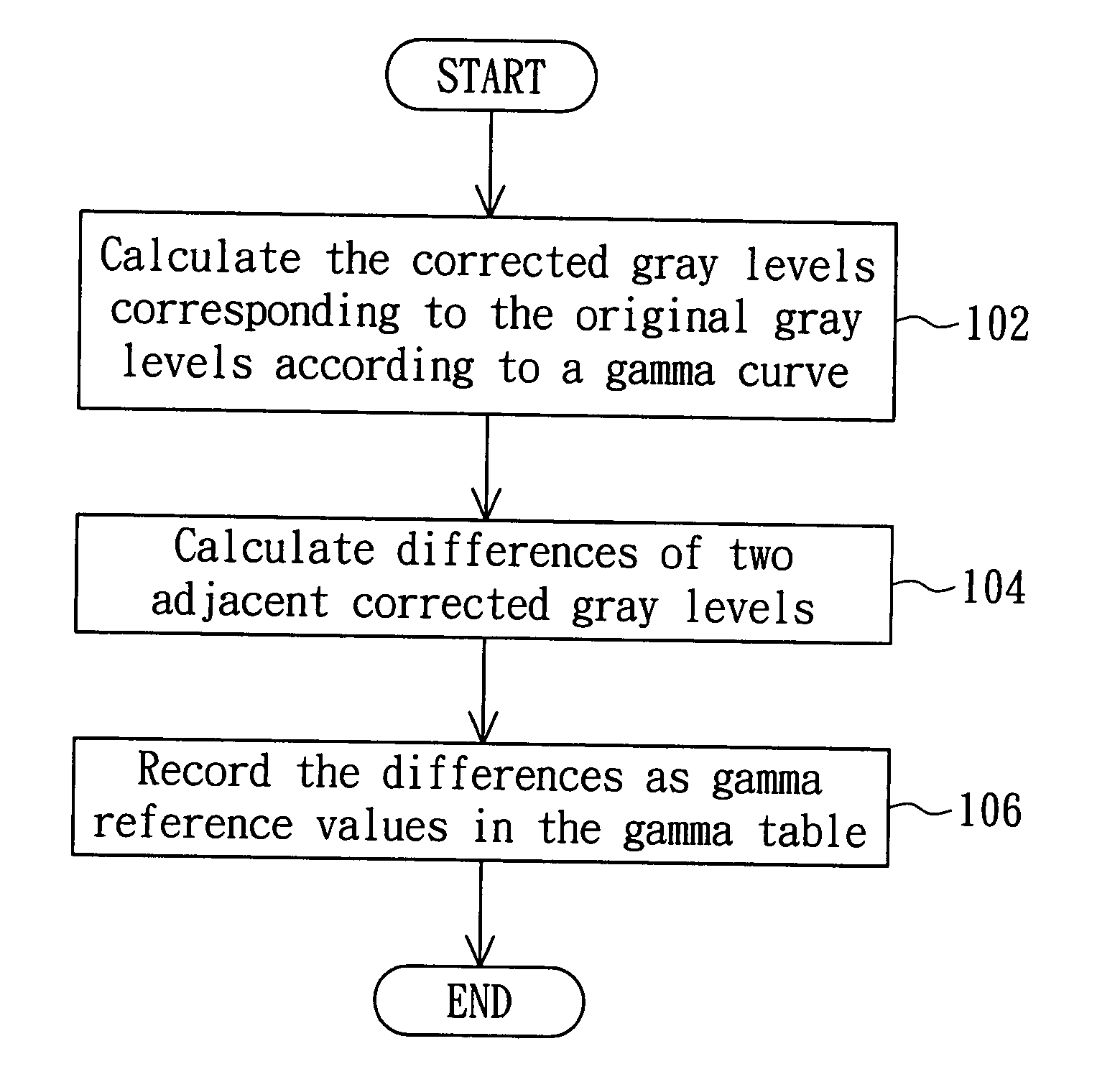

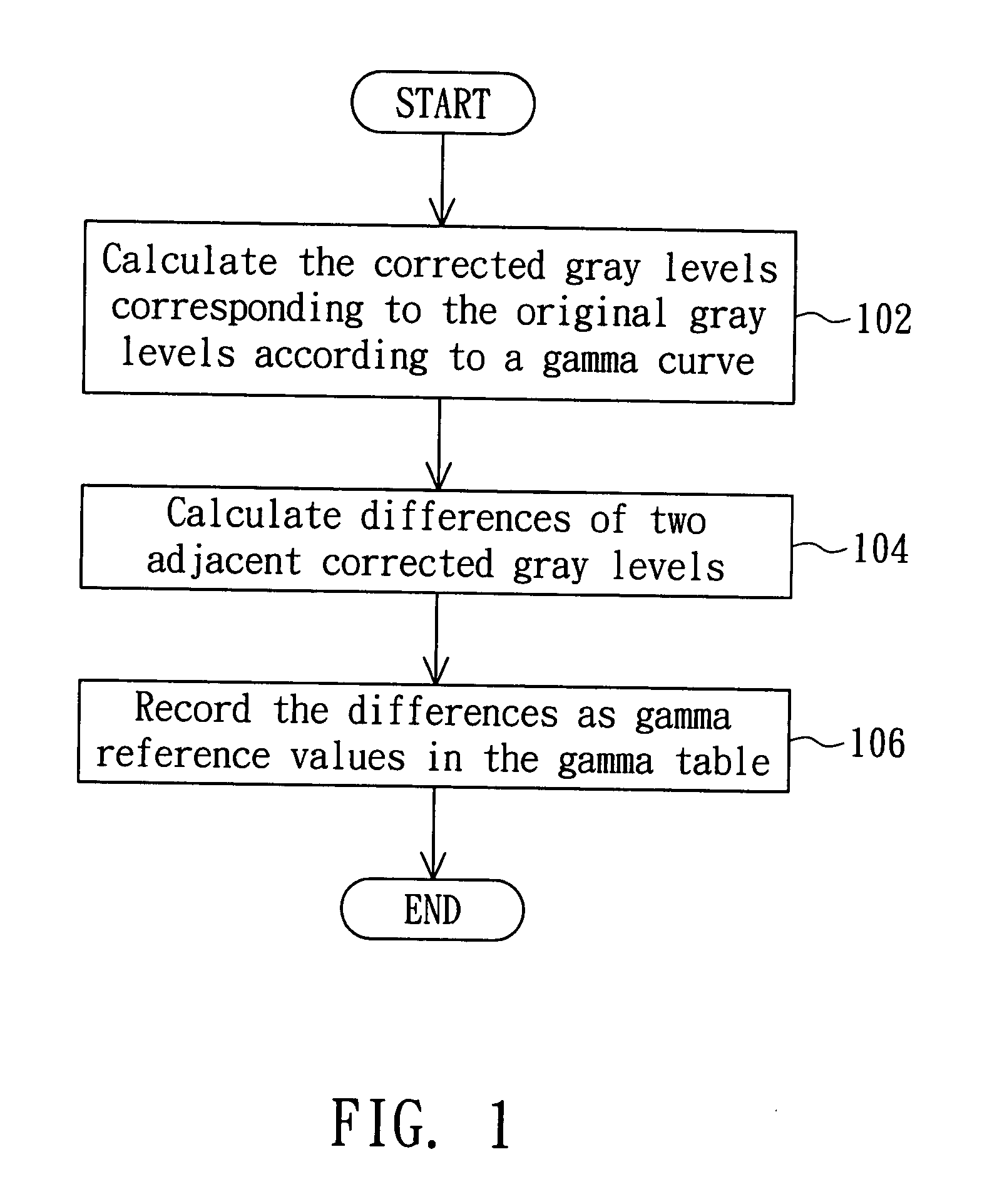

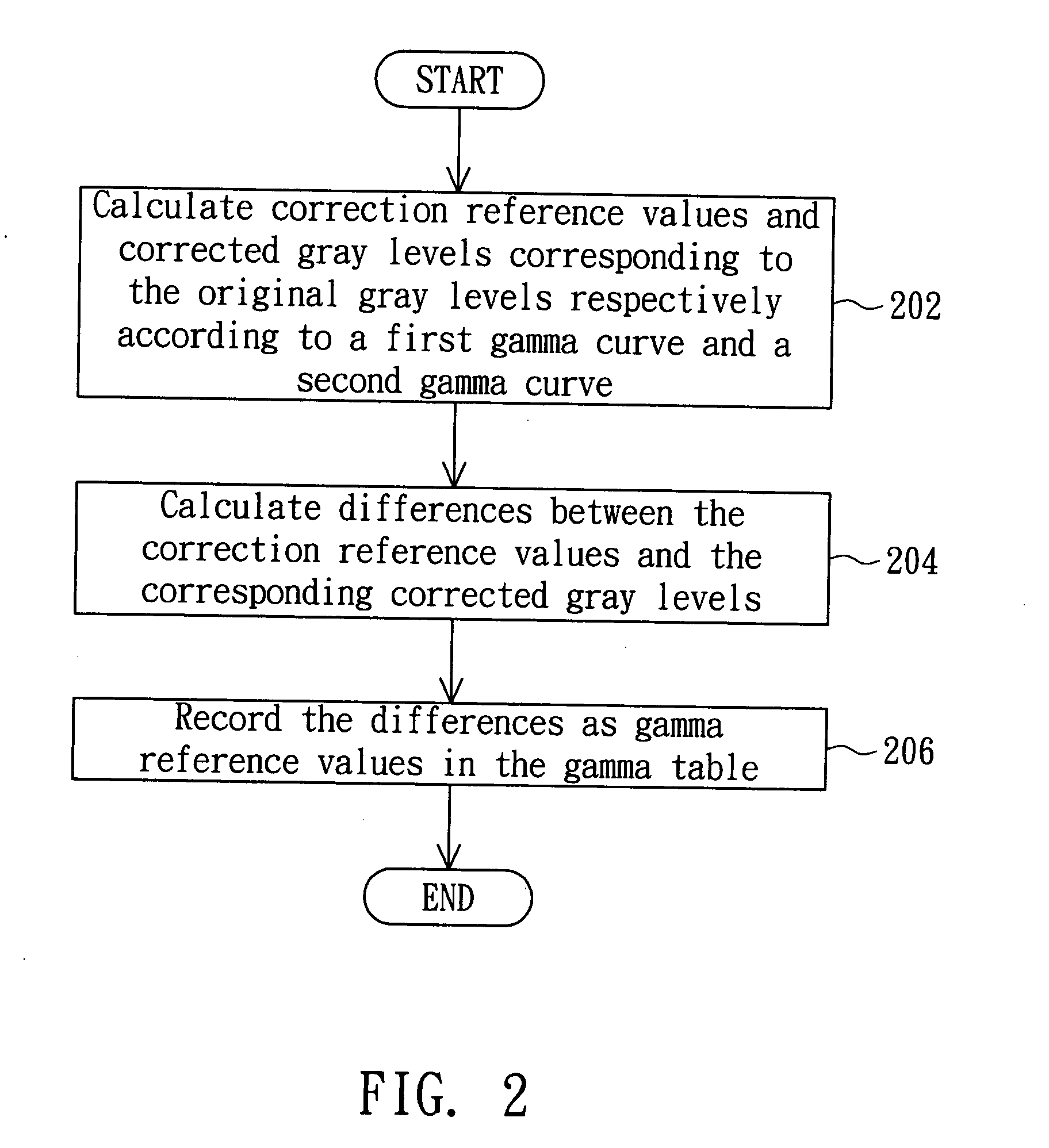

Method for generating a gamma table

InactiveUS20080007575A1Save memory spaceCathode-ray tube indicatorsInput/output processes for data processingGray levelDisplay device

Owner:HIMAX TECH LTD

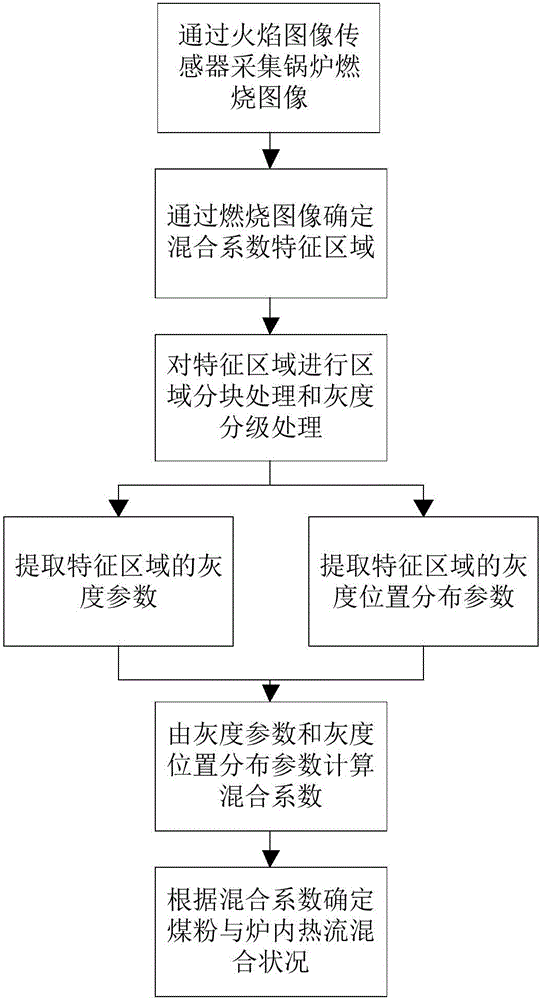

Measurement method of coal dust and in-furnace heat flow mixing effect on the basis of combustion image

InactiveCN105912872ARealize online monitoringAccurate calculationImage analysisInformaticsImaging processingHeat flow

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

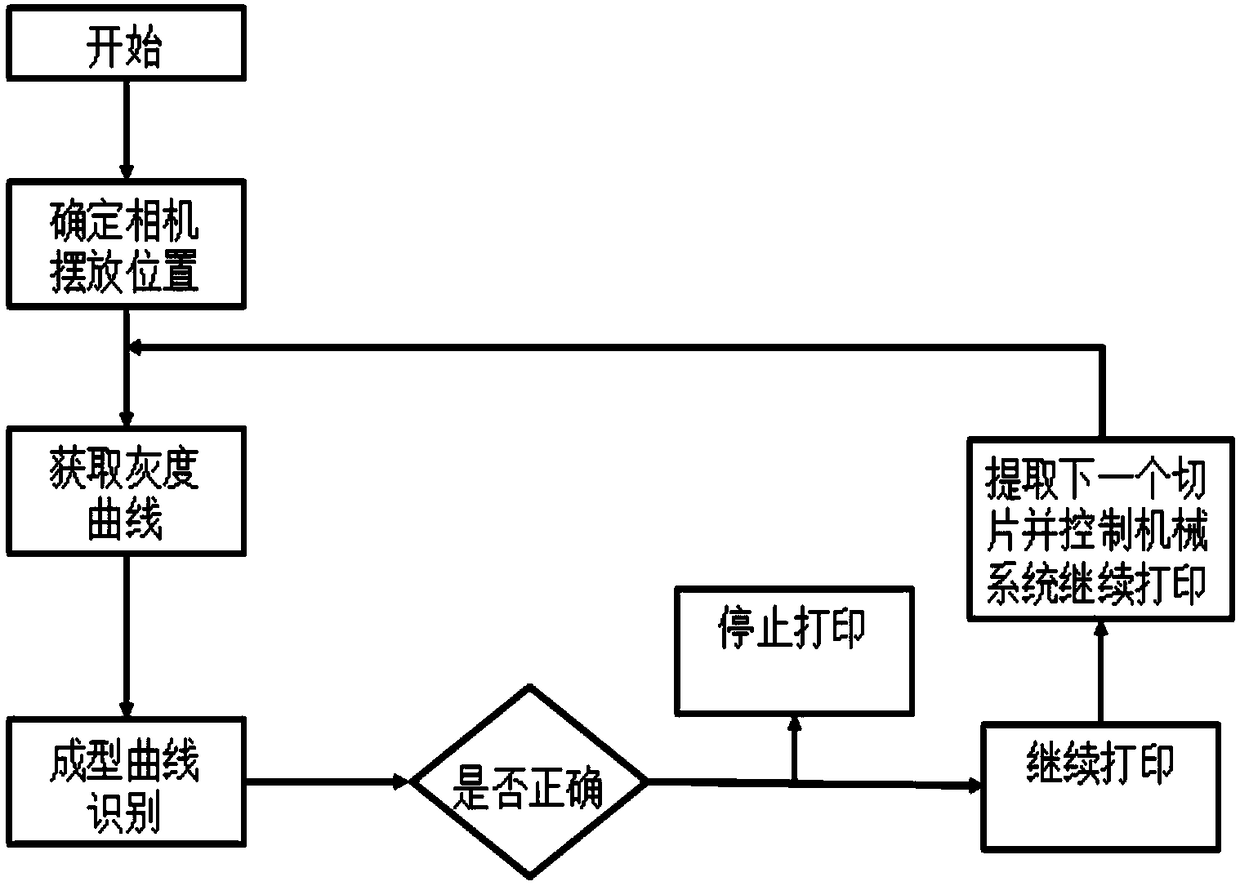

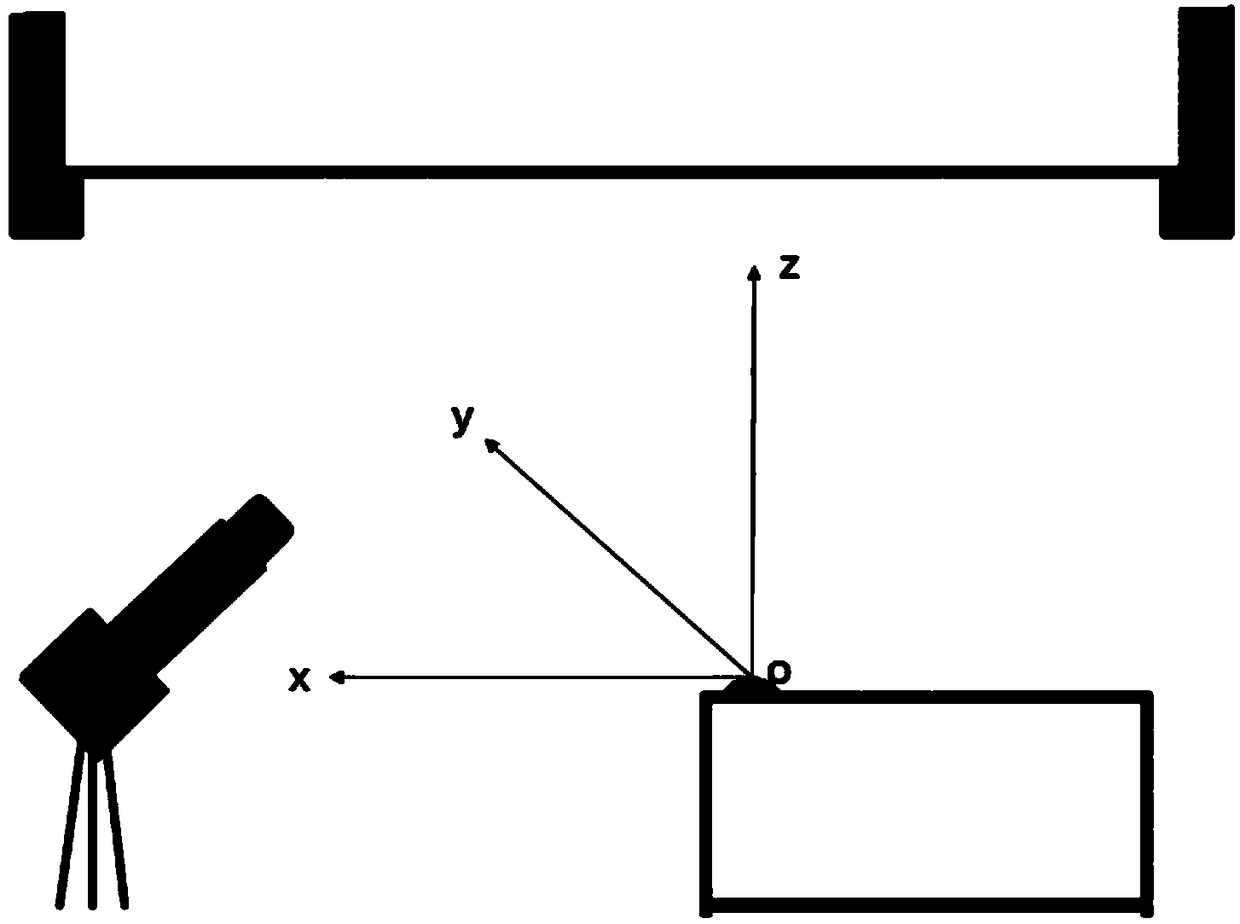

Vision monitoring feedback method for face exposure 3D printing

ActiveCN108724733AAdditive manufacturing apparatusCharacter and pattern recognitionImpact monitoringGray level

Owner:BEIJING UNIV OF TECH

Image sharpness device and method

Owner:AU OPTRONICS CORP

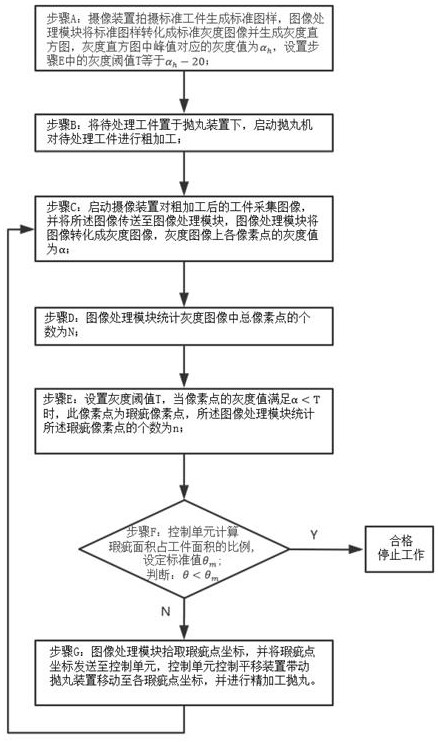

Workpiece surface treatment method based on image recognition and shot blasting machine

Owner:YANCHENG INST OF TECH

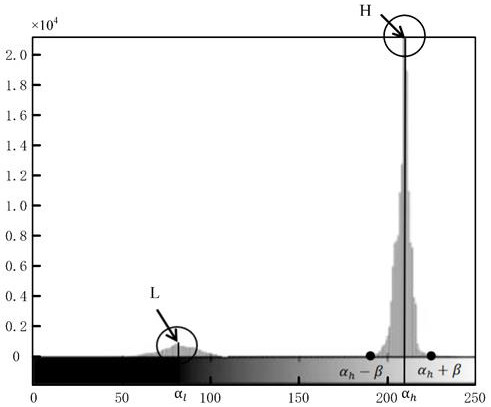

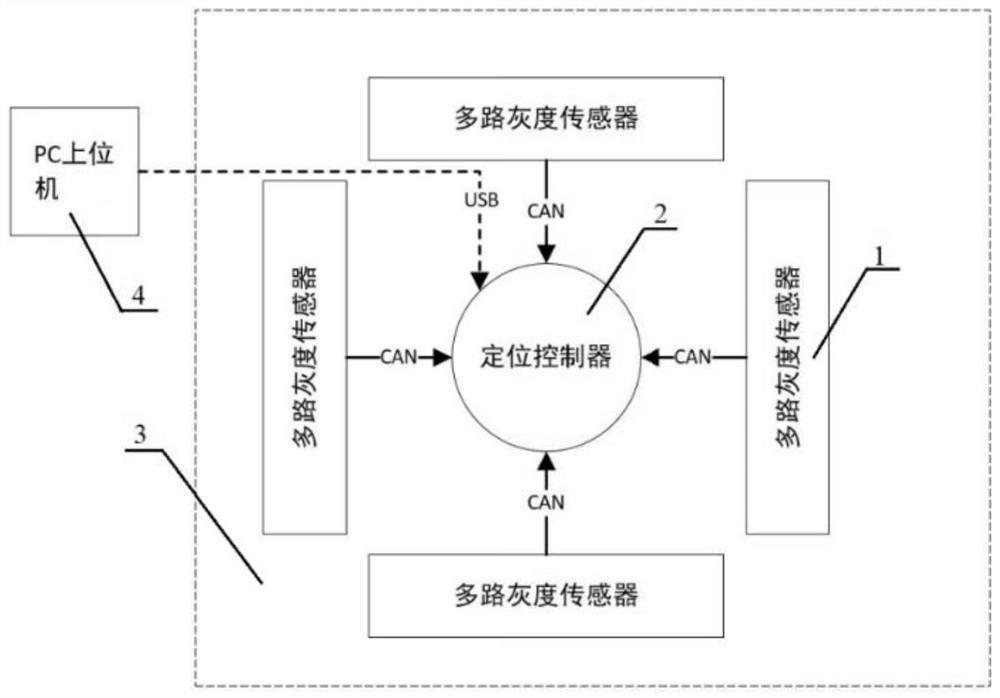

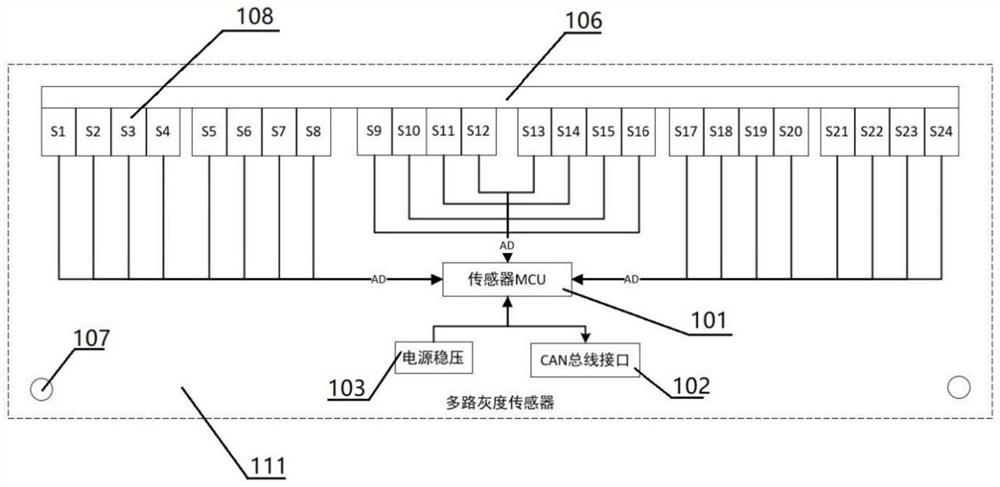

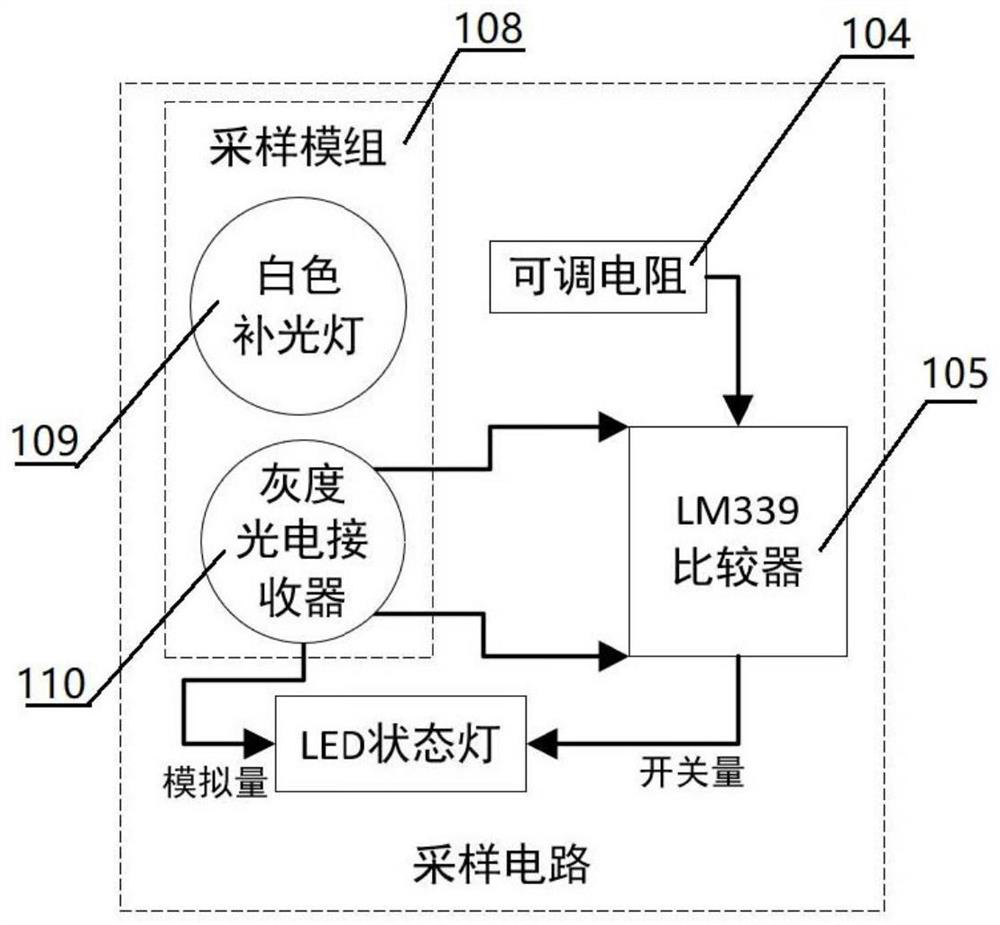

Auxiliary positioning system and positioning method based on four-wheel omnidirectional chassis

PendingCN113238553AIncrease speedPosition/course control in two dimensionsVehiclesGray levelControl engineering

Owner:QILU UNIV OF TECH +1

Row-modulation gray-level LCD device and method thereof

A row (common electrode)-modulation gray-level LCD device and a method thereof, which use a row-modulation device to input at least two sequentially generated original common voltage signals to the common electrode of the same row, whereby the sequentially generated original common voltage signals cooperate with the segment voltage signals to generate voltage differences in the common electrode and turn on or turn off the same monochromatic pixel in a time-division mode. The accumulated effect of the time-division turn-on and turn-off states enables the same monochromatic pixel to present gray-pixel.

Owner:POWERTIP TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap