Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Hinge point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

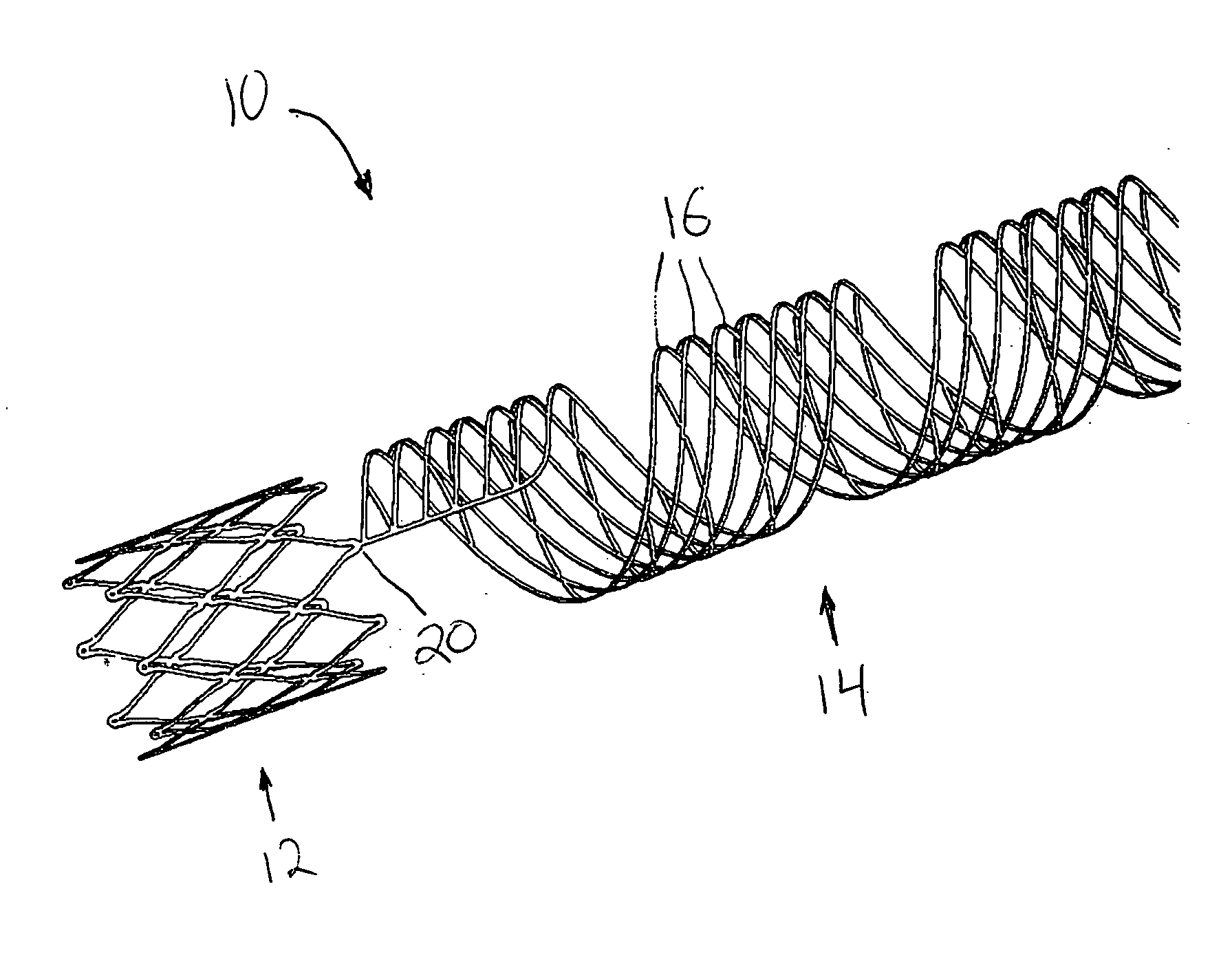

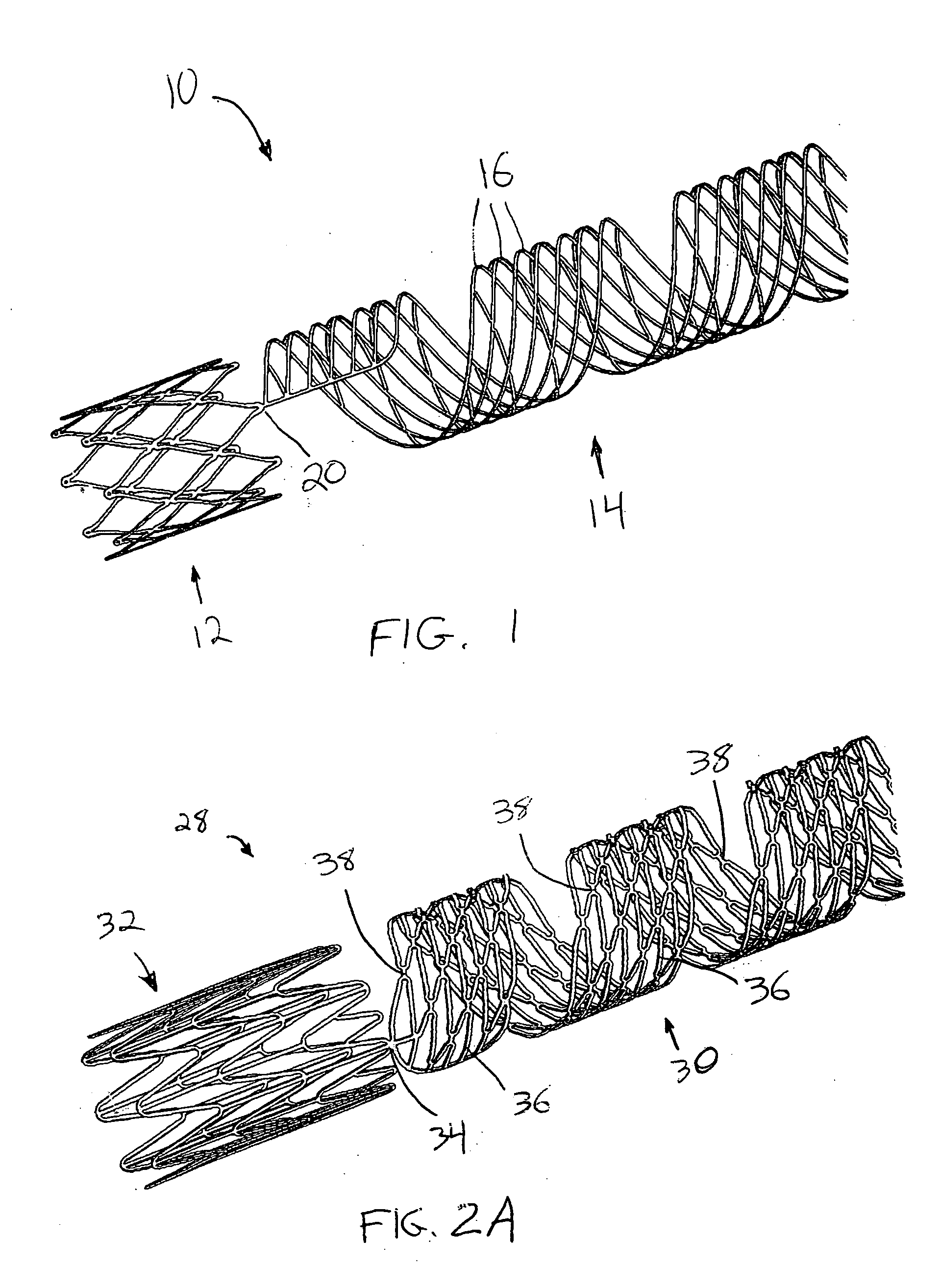

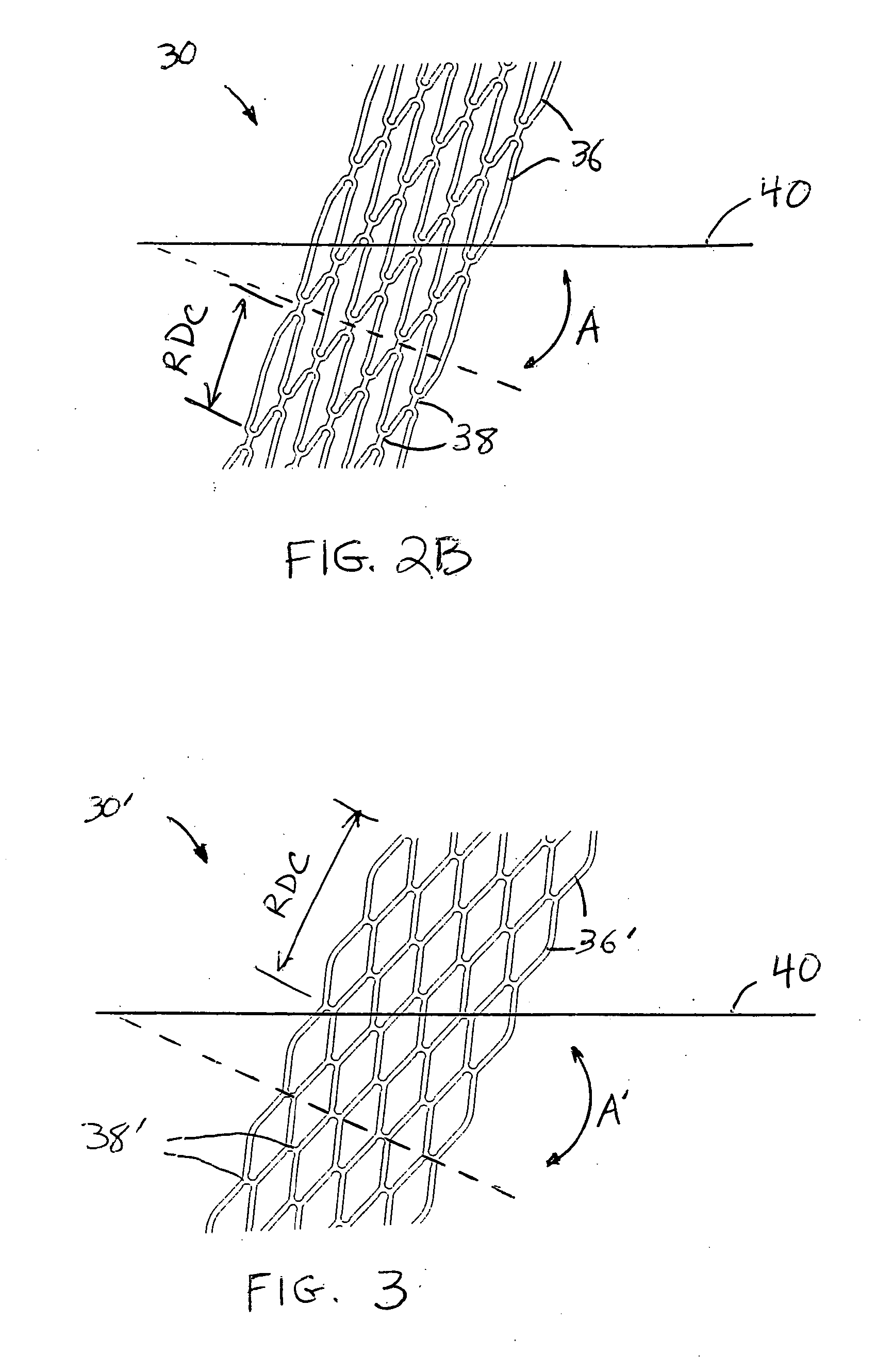

Vascular prothesis having flexible configuration

InactiveUS20050033410A1Increase flexibilityReduced delivery profileStentsBlood vesselsBiomedical engineeringHinge point

Owner:NOVOSTENT CORP

Whole forming method for cylindrical netting support with horizontal sliding structure

InactiveCN1472408AImprove installation accuracyImprove construction qualityBuilding constructionsEngineeringMechanical engineering

A construction method for integrally formed cylindrical reticulated shell with horizontal slide structure is disclosed. A cylindrical reticulated shell is divided into two segments for individual assembly. Its one end is a fixing hinge and its another end is a slide hinge in slide way. The hinged points between two segments are borne on temporary supporter. Both slide hinges are horizontally moving until they reach designed positions and the slide hinges are fixed to base. When hinged point reached designed height, a horizontal rod is linked to fix the hinged points. Its advantages are short period, and low cost.

Owner:ZHEJIANG GUOSHENG STEEL STRUCTURE CO LTD

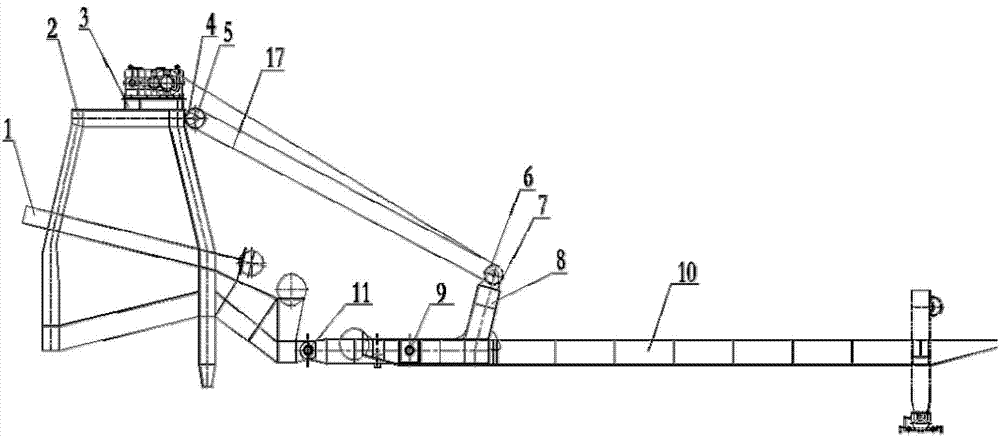

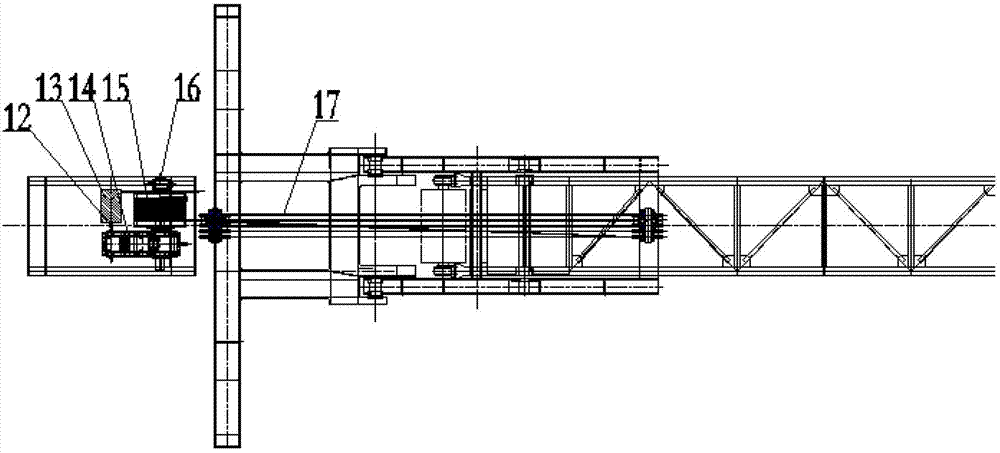

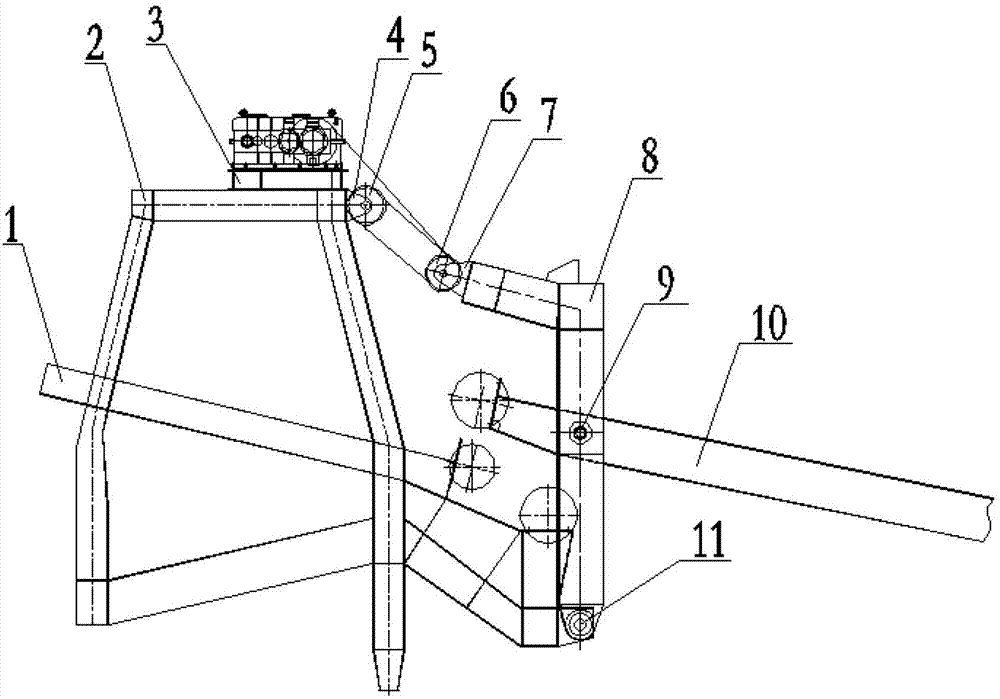

Two tripper cars of electric variable-amplitude type wheel-bucket stack-taking machine

InactiveCN102765606ASave design spaceReduce weightWinding mechanismsLoading/unloadingSmall footprintEngineering

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

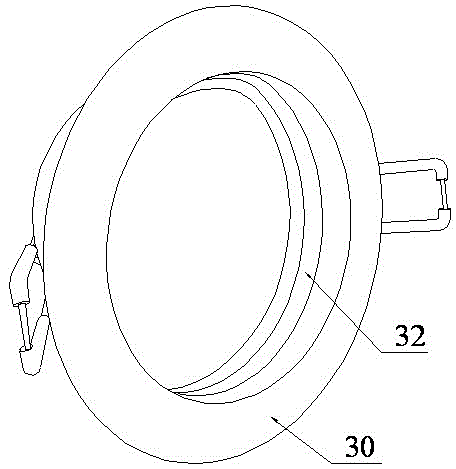

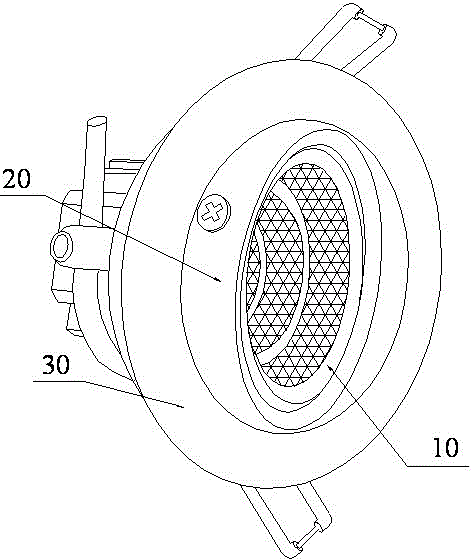

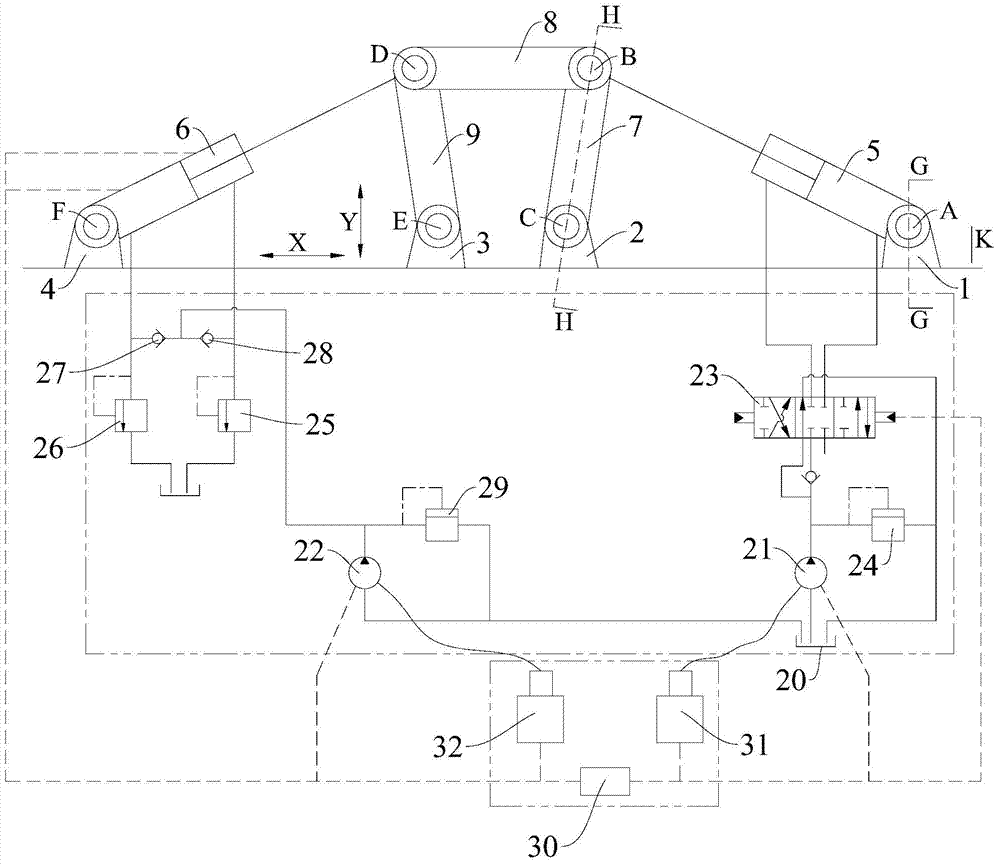

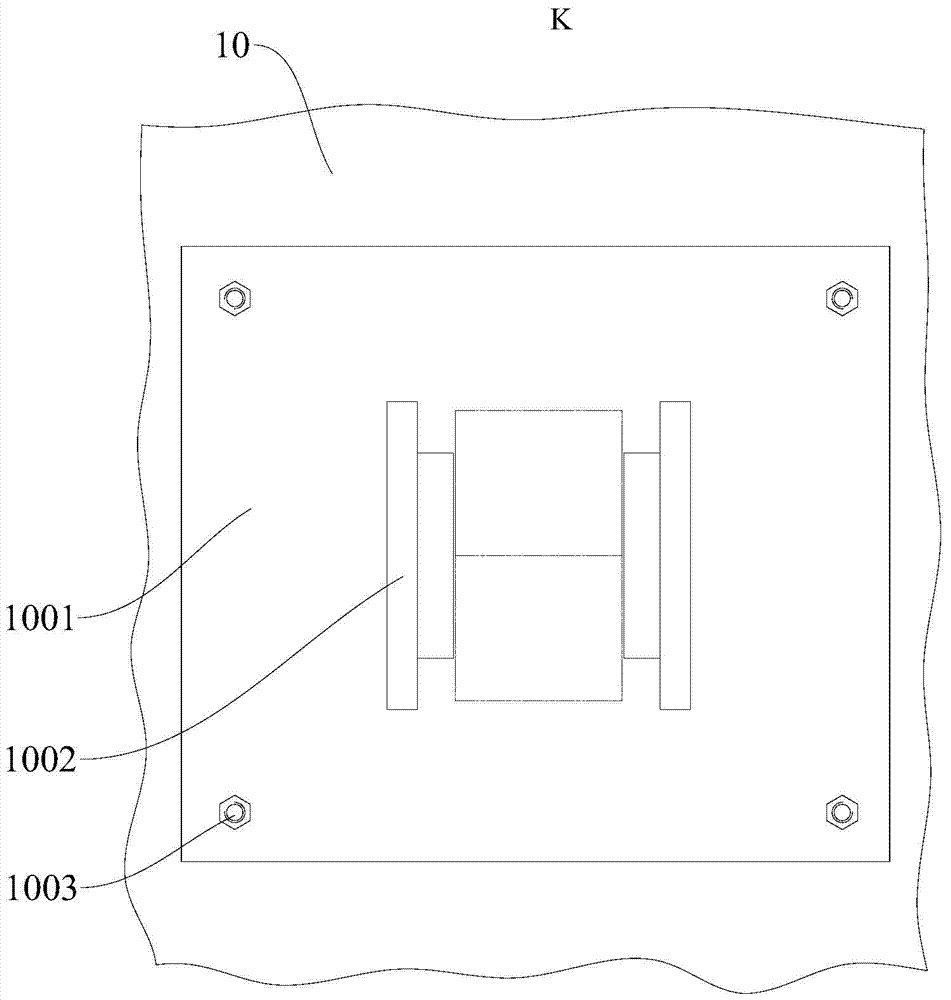

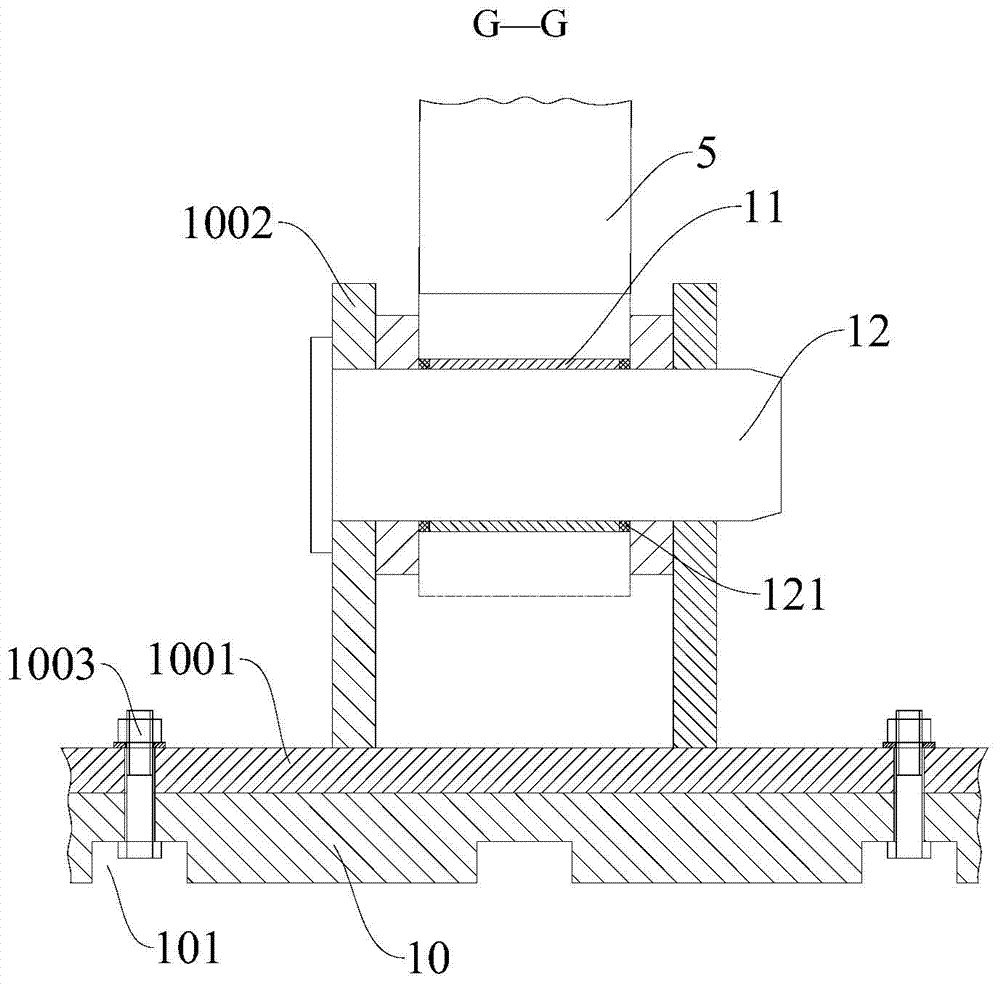

Shaft sleeve abrasion testing system

InactiveCN103592123AImprove test efficiencyMachine gearing/transmission testingPetroleum engineeringHinge point

Owner:SANY HEAVY MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap