Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Medium pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The medium pressure range of industrial air compressors from the technology leader in high pressure features continuous duty rated, 3-stage, air cooled, pressure lubricated compressors for the most demanding requirements. The full-featured control system allows for unattended, automatic operation.

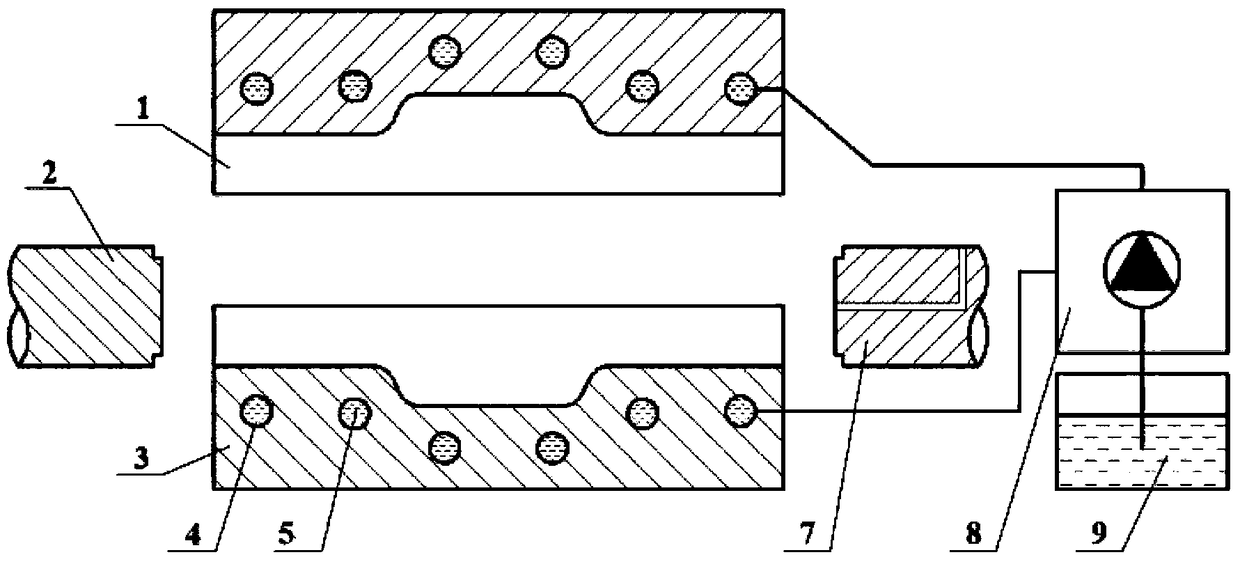

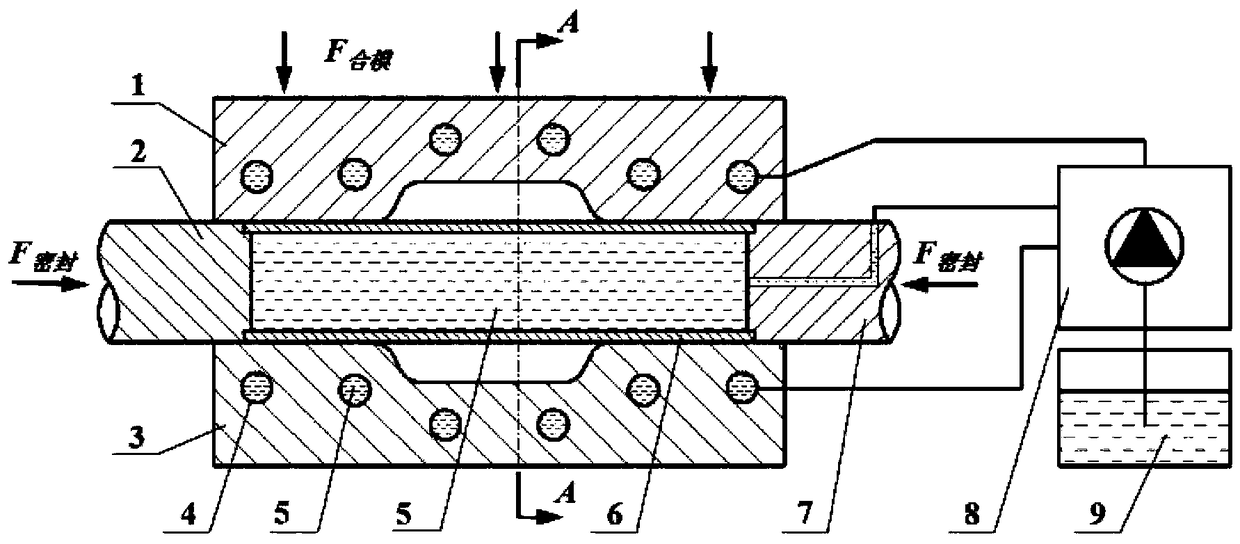

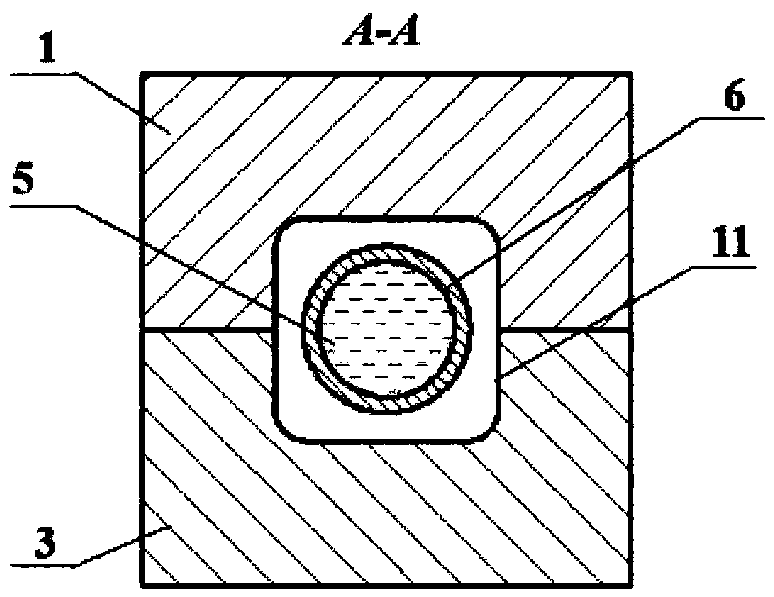

Aluminum alloy special-shaped pipe ultralow temperature medium pressure forming method

ActiveCN109500195AAvoid cracking problemsAchieving flexible loadingShaping toolsWeld seamAbnormal shaped

Owner:DALIAN UNIV OF TECH

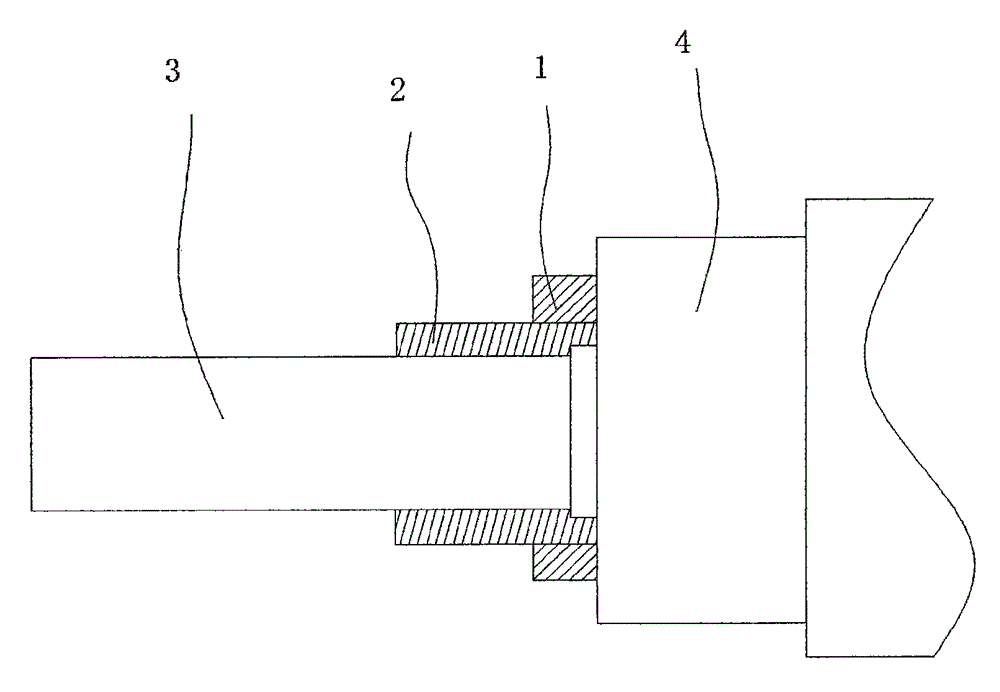

Method for crimping high-pressure cross-linking three-layer co-extrusion continuous produced disc-exchanging conductor

InactiveCN102945710ANo drop in tensile strengthLow technical requirementsConnections effected by permanent deformationCable/conductor manufactureCross-linkElectrical resistance and conductance

Owner:HENGYANG HENGFEI CABLE CO LTD

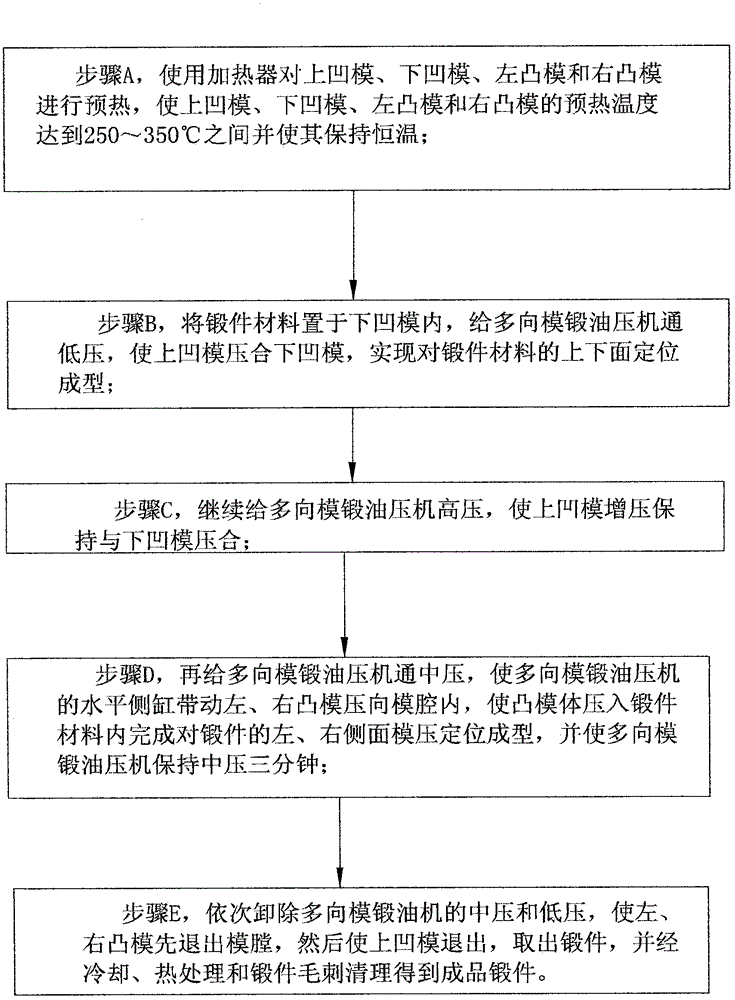

Left and right convex-mold die-forging process

InactiveCN104399853AStreamline distribution is reasonableImprove mechanical propertiesUpsetting pressesSwagging pressesRight convexHigh pressure

Owner:浙江双杰锻造有限公司

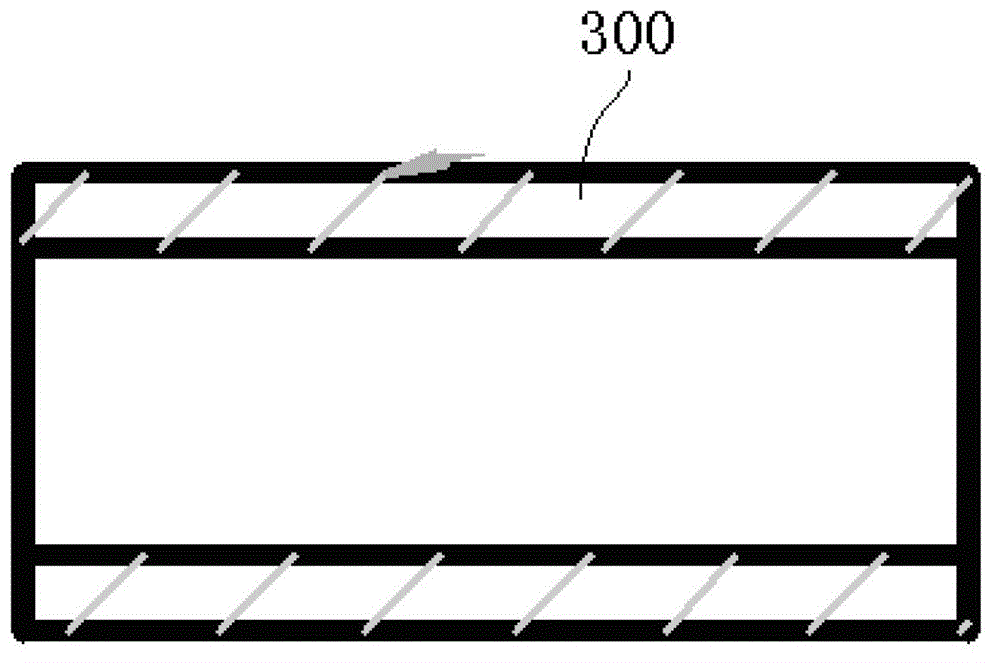

Solar panel fixing device

PendingCN107872190AAchieve fixationSimplify the assembly processPhotovoltaic supportsPhotovoltaic energy generationReciprocating motionEngineering

The invention provides a solar panel fixing device. The solar panel fixing device includes an edge pressing fixation structure and a middle pressing fixation structure. The edge pressing fixation structure includes an edge pressing assembly. The edge pressing assembly includes an edge pressing substrate and an edge pressing clamp piece capable of moving towards the edge pressing substrate in a reciprocating manner so as to fit with the edge pressing substrate to clamp a frame structure. An edge pressing limit cord abutting against a side face of the frame structure facing towards the edge pressing assembly is arranged on the edge pressing substrate in a protruding manner. The middle pressing fixation structure includes a middle pressing assembly. The middle pressing assembly includes a middle pressing substrate and a middle pressing clamp piece capable of moving towards the middle pressing substrate in a reciprocating manner so as to fit with the middle pressing substrate to clamp theframe structure. Two middle pressing limit cord are arranged on the middle pressing substrate in a protruding manner. By the arrangement of the edge pressing substrate and the middle pressing substrate, a worker does not need to observe that whether the frame structure reaches a preset position or not repeatedly, so that time required for determining that the frame structure reaches the preset position is shortened, the edge board fixation is realized, the whole assembly process is simple and quick and is short in time consumption and high in assembly efficiency.

Owner:QINGHAI TOPRAY SOLAR CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap