Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Resistance wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistance wire is wire intended for making electrical resistors (which are used to control the amount of current in a circuit). It is better if the alloy used has a high resistivity, since a shorter wire can then be used. In many situations, the stability of the resistor is of primary importance, and thus the alloy's temperature coefficient of resistivity and corrosion resistance play a large part in material selection.

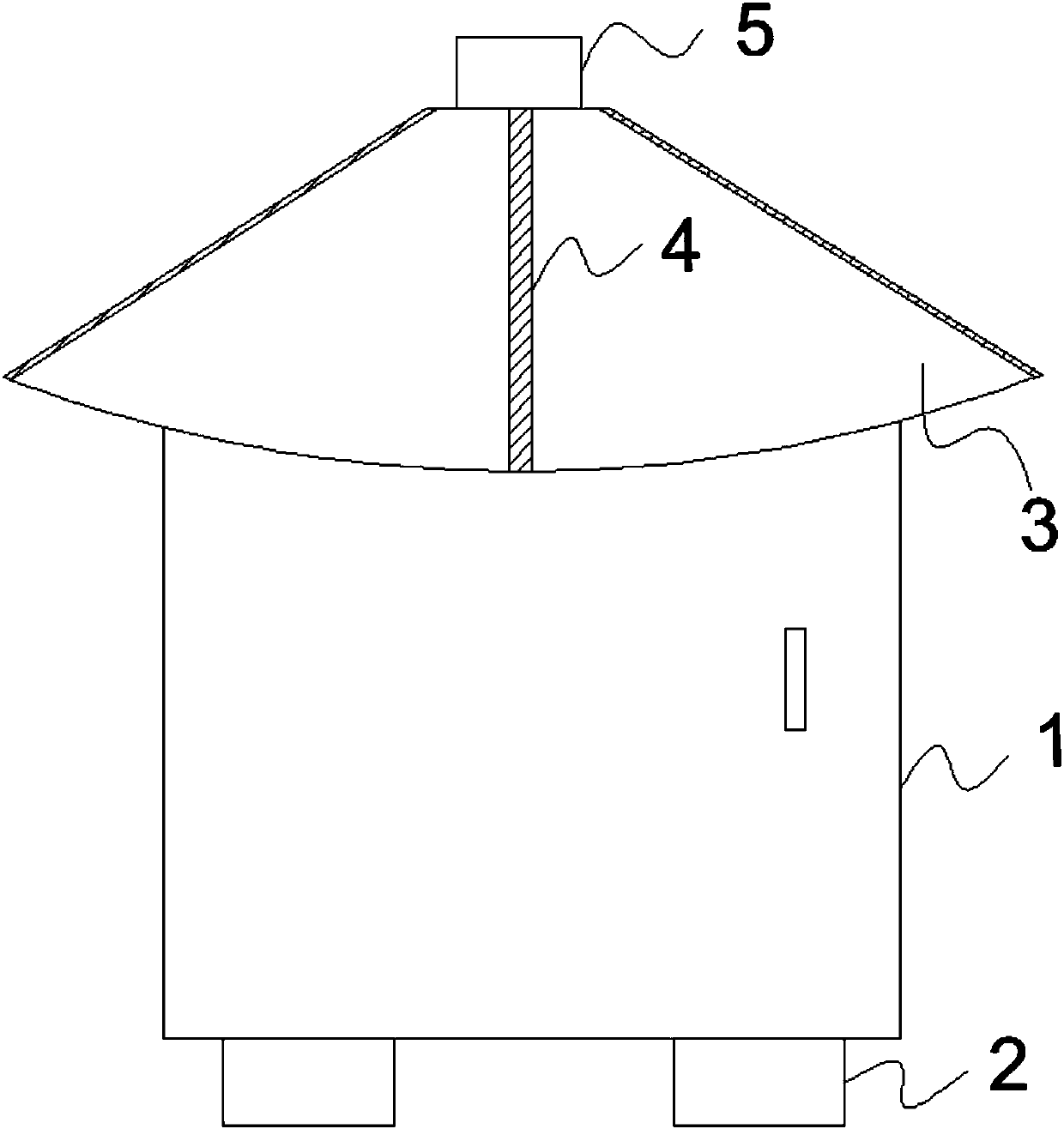

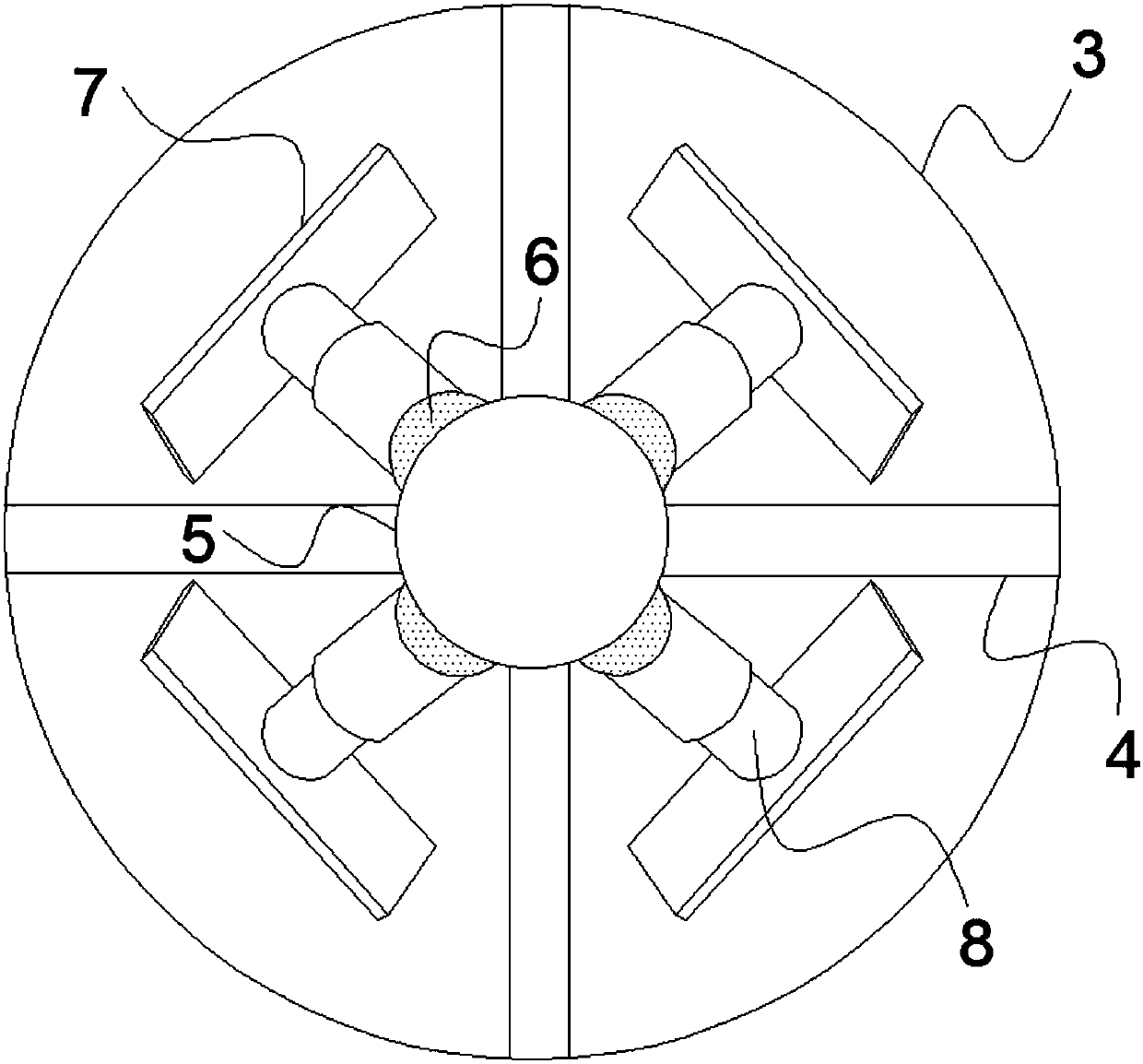

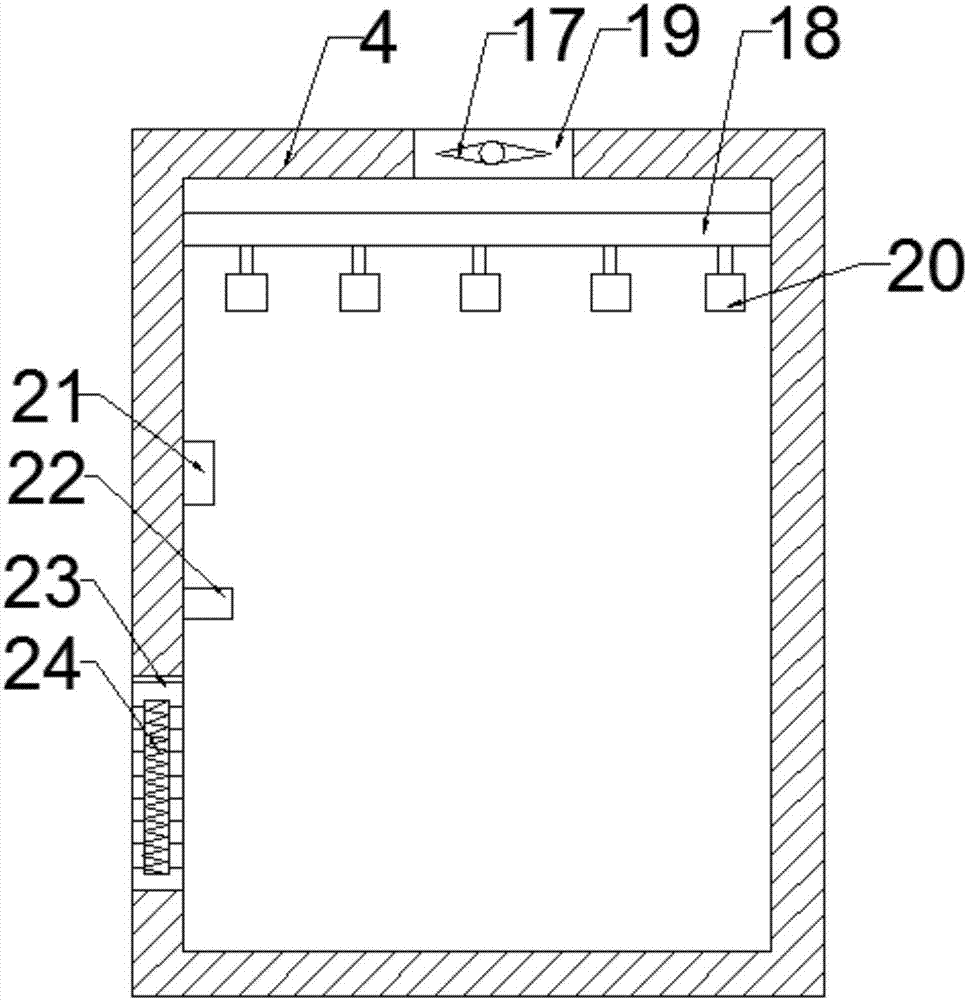

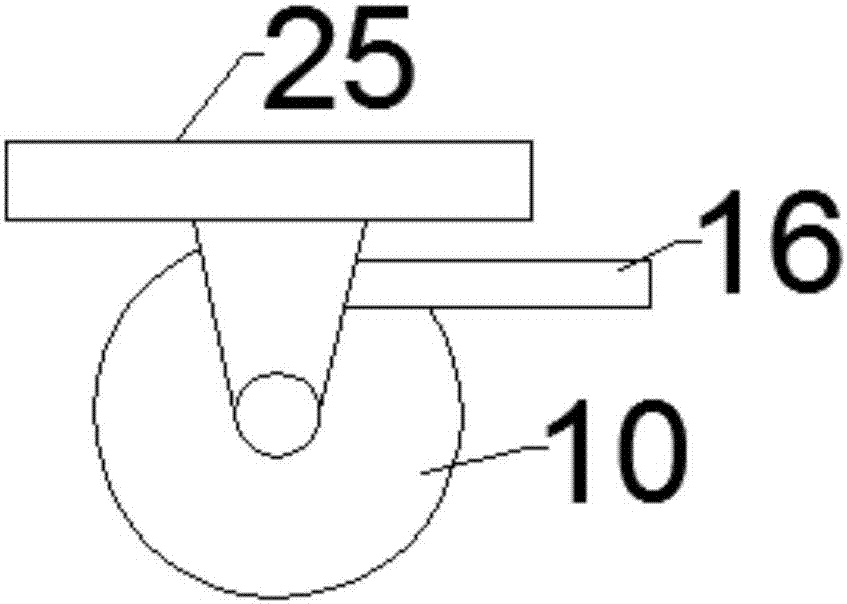

Outdoor rainproof and snow-protecting distribution box cabinet

ActiveCN107946959AUnder pressurePrevent penetrationSubstation/switching arrangement casingsAnti-seismic devicesEnvironment effectEngineering

Owner:高原(山东)机电设备有限公司

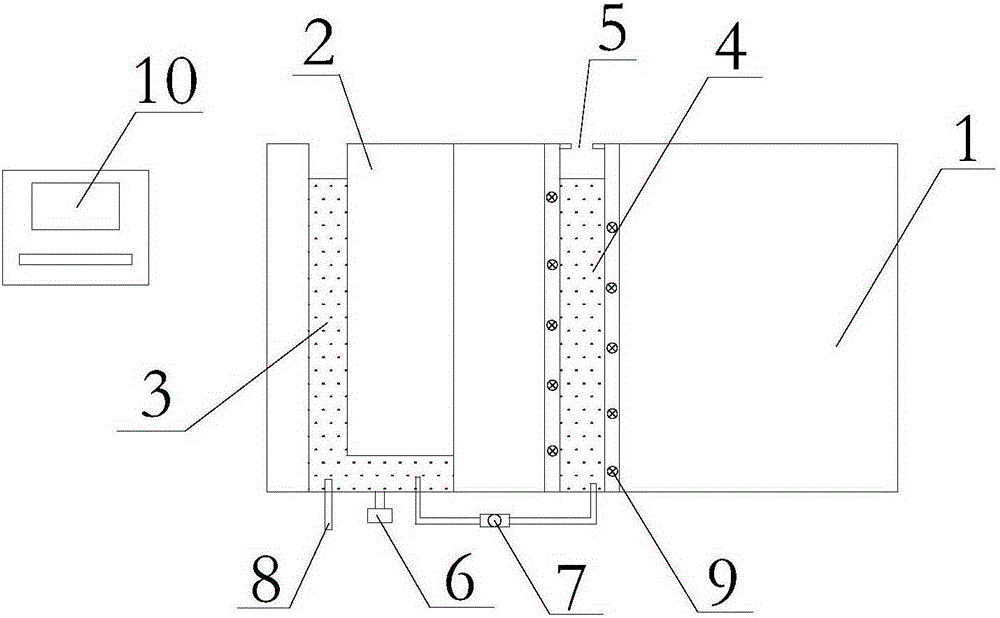

Molten lead dissolving and conveying system

InactiveCN104043810AHigh temperature control accuracyPrevent solidificationMolten metal conveying equipmentsCasting parameters measurement/indication devicesTemperature controlEngineering

Owner:TIANNENG BATTERY WUHU

RGB synchronous intelligent light string

ActiveCN108278566AColor effect switchingIncrease diversityLight source combinationsElectric circuit arrangementsMOSFETTransformer

The invention discloses an RGB synchronous intelligent light string. The RGB synchronous intelligent light string comprises an intelligent power supply, a controller, light strings and a main circuit,wherein the plurality of light strings are connected in parallel with the main circuit; the intelligent power supply is connected with the controller; the controller is connected with the main circuit; a 220 V voltage is accessed into one end of an IP44 plug; the other end of the plug is accessed into a resistance wire for current protection, a piezoresistor for voltage limiting control, a filterfor noise filtration and signal separation and a filtering circuit for high-frequency resistance and low-frequency passing; an output end of the filtering circuit is connected to an input end of an MOSFET and a DCDC transformer; the DCDC transformer outputs direct current of which the voltage is changed into a driver and an IRF; the IRF is connected with a program module, a remote control module,a WiFi module and a Bluetooth module; a signal output by the IRF passes through a driving module; the driving module and an output end of the DCDC transformer are connected to the input end of the MOSFET; and an output end of the MOSFET is connected to an end part of the main circuit. The RGB synchronous intelligent light string can simultaneously control the colors of the plurality of light strings to improve a decorative effect.

Owner:JIANGSU LEDCO LIGHTING TECH CO. LTD

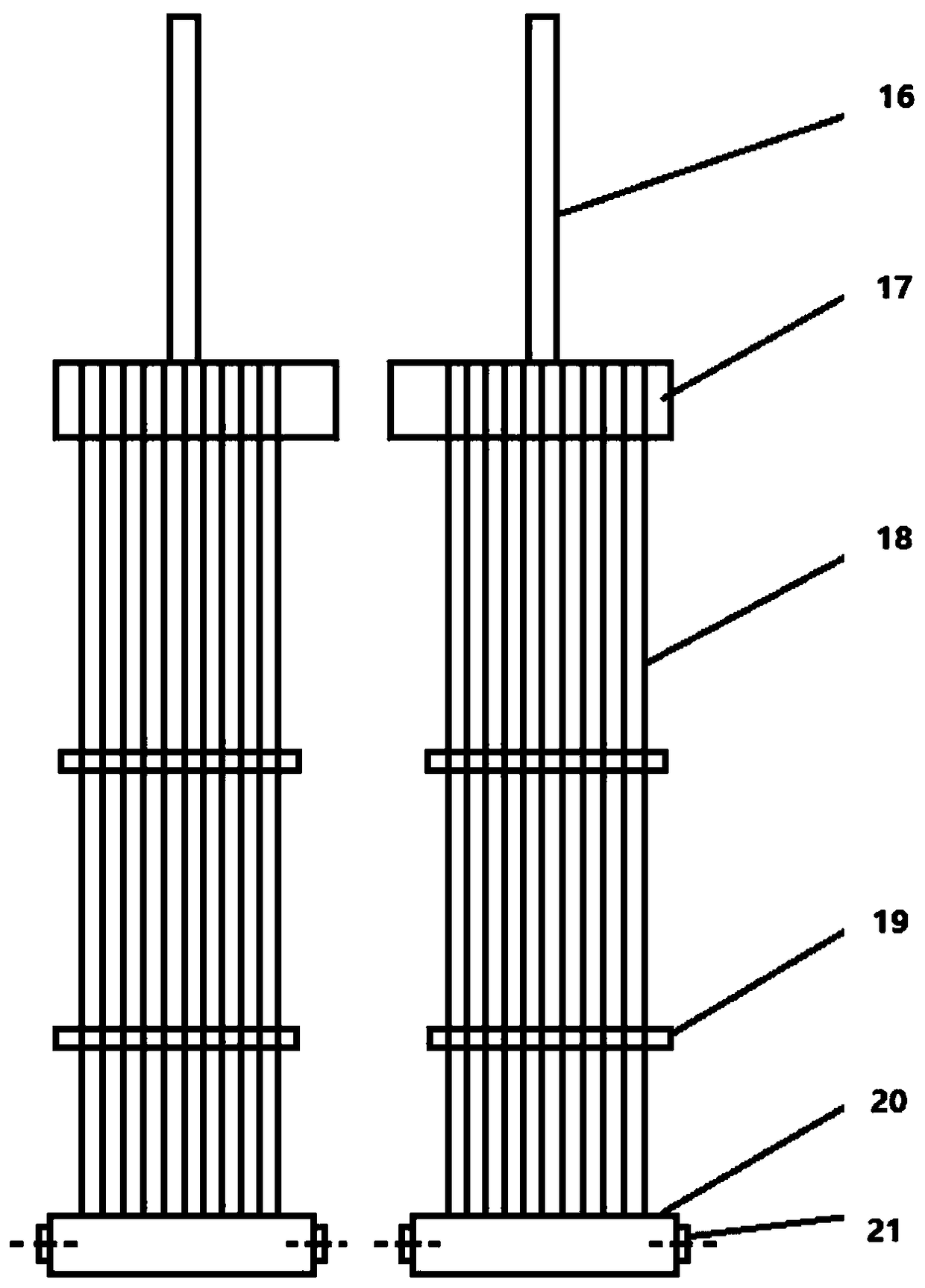

Processing technology of iron-chromium-aluminum resistance wire

InactiveCN104637640AResistor manufactureElectric furnacesResistance wire

Owner:DANYANG ZHISHENG ALLOY

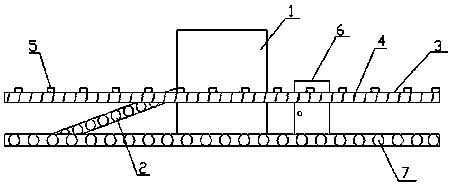

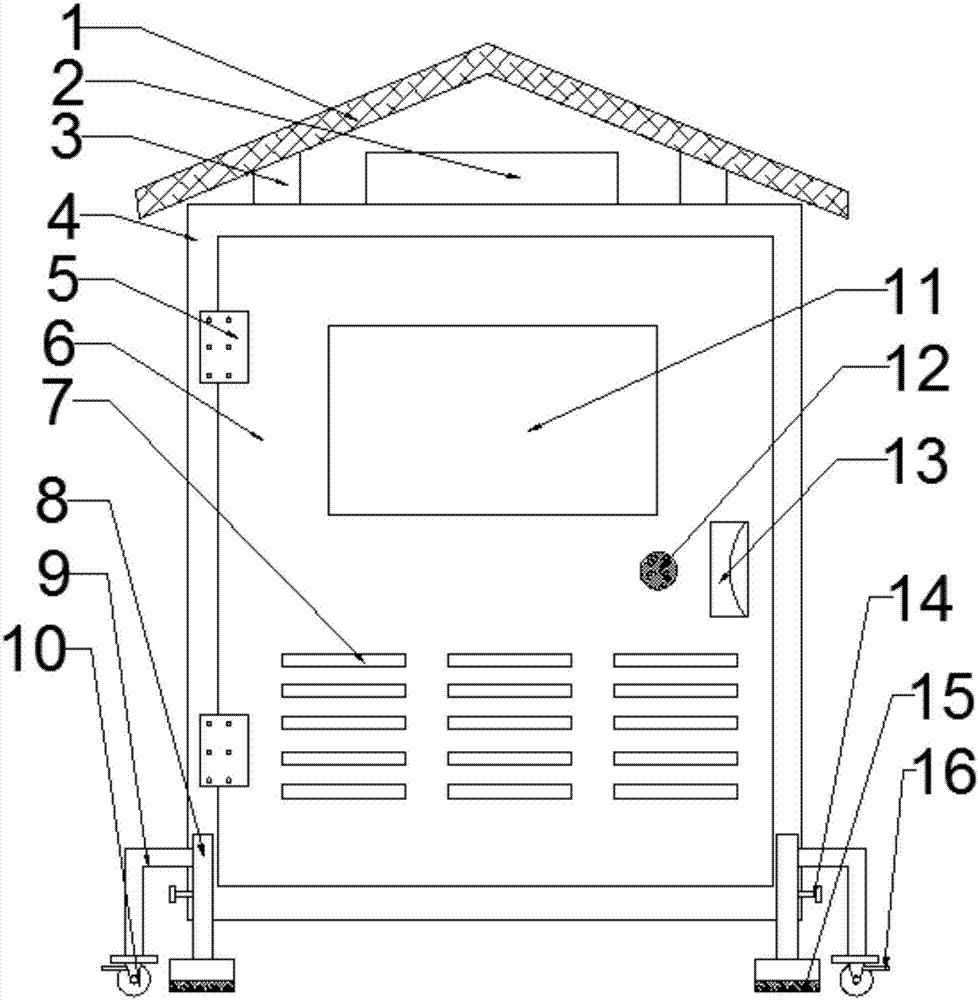

Antitheft electric power cabinet convenient for moving and fixing

InactiveCN107968324ASubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsFingerprintResistance wire

Owner:李秋平

High-precision resistance type heating furnace for medium-low-temperature optical fiber drawing tower

Owner:西安思翰光电科技有限公司

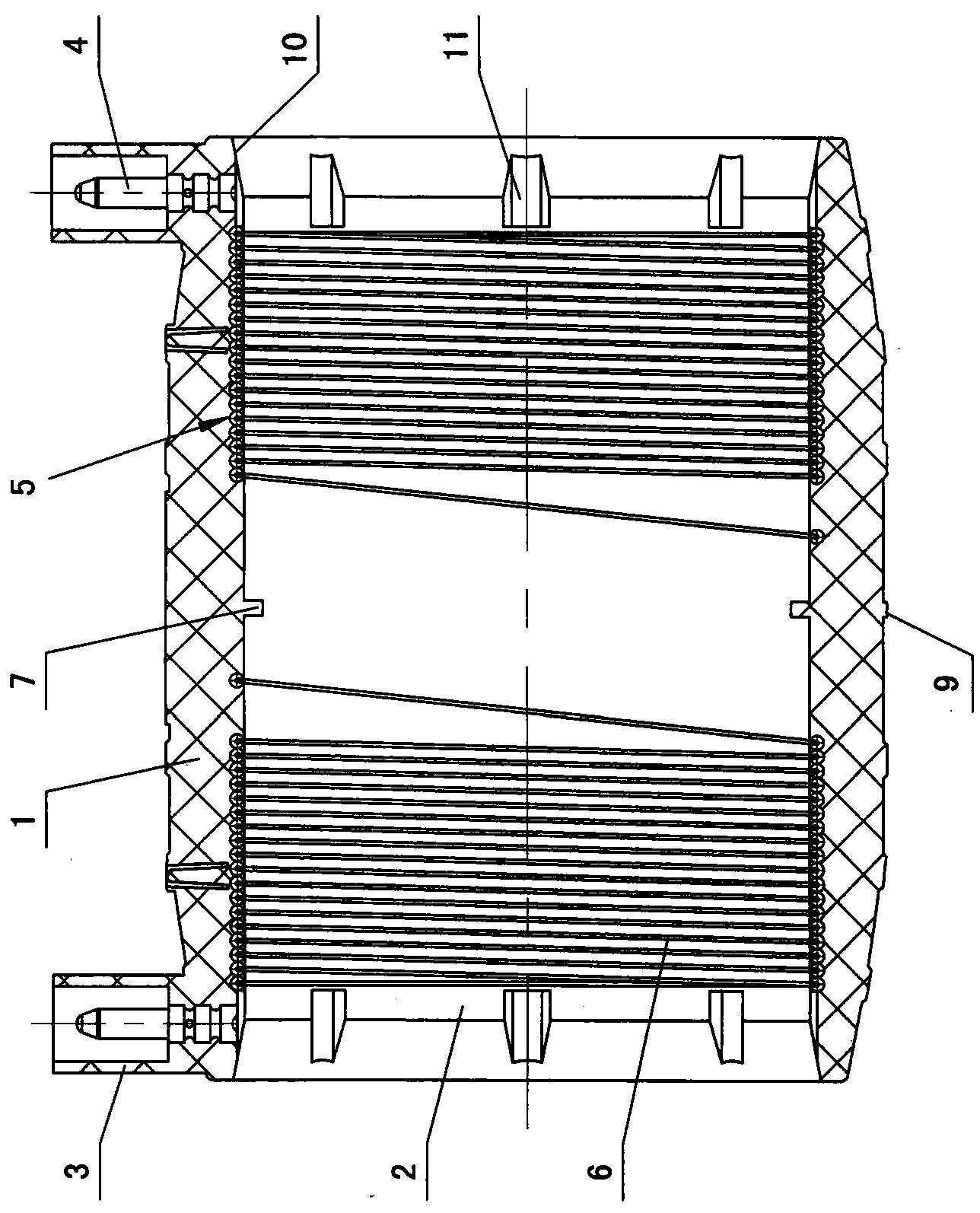

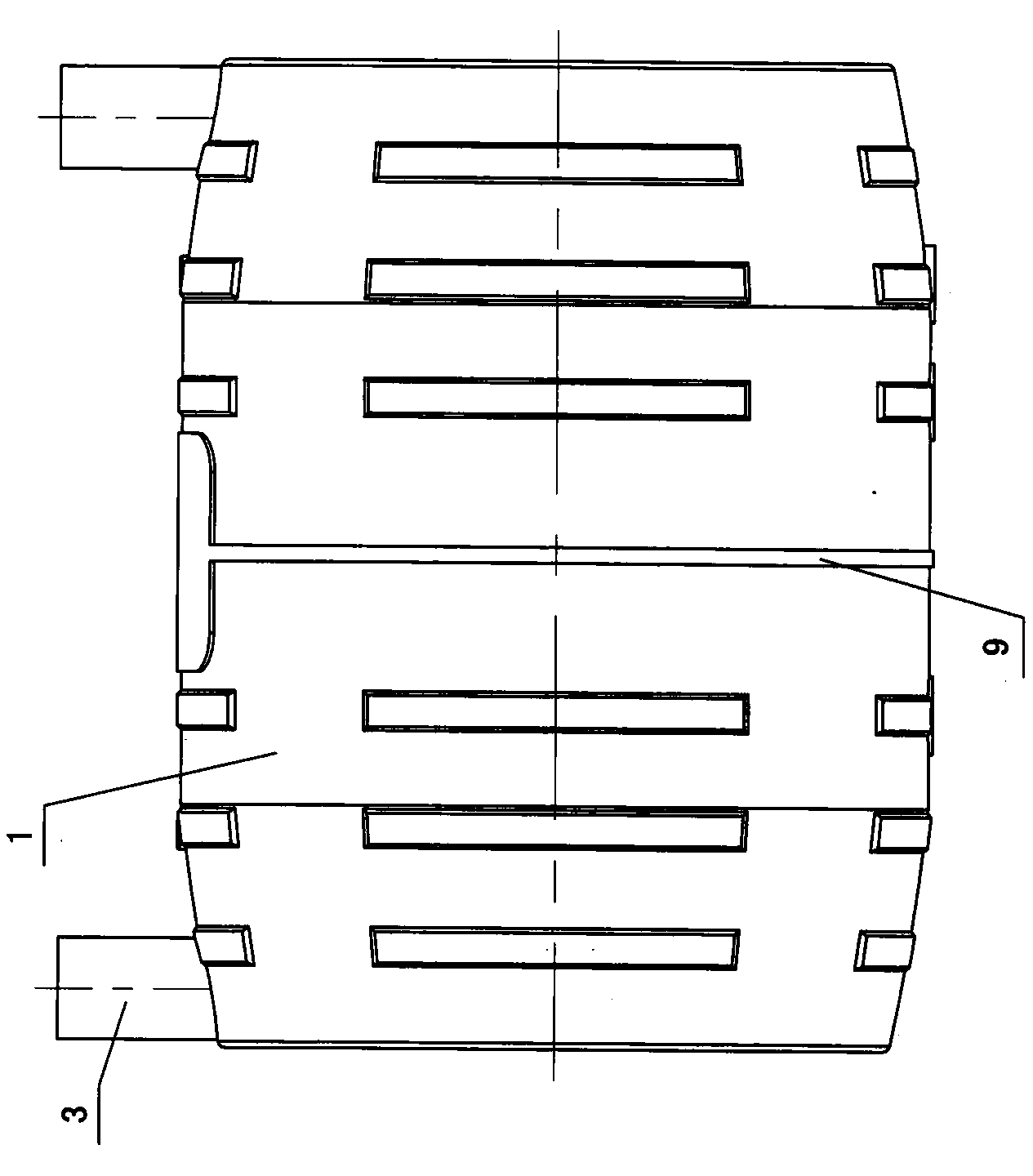

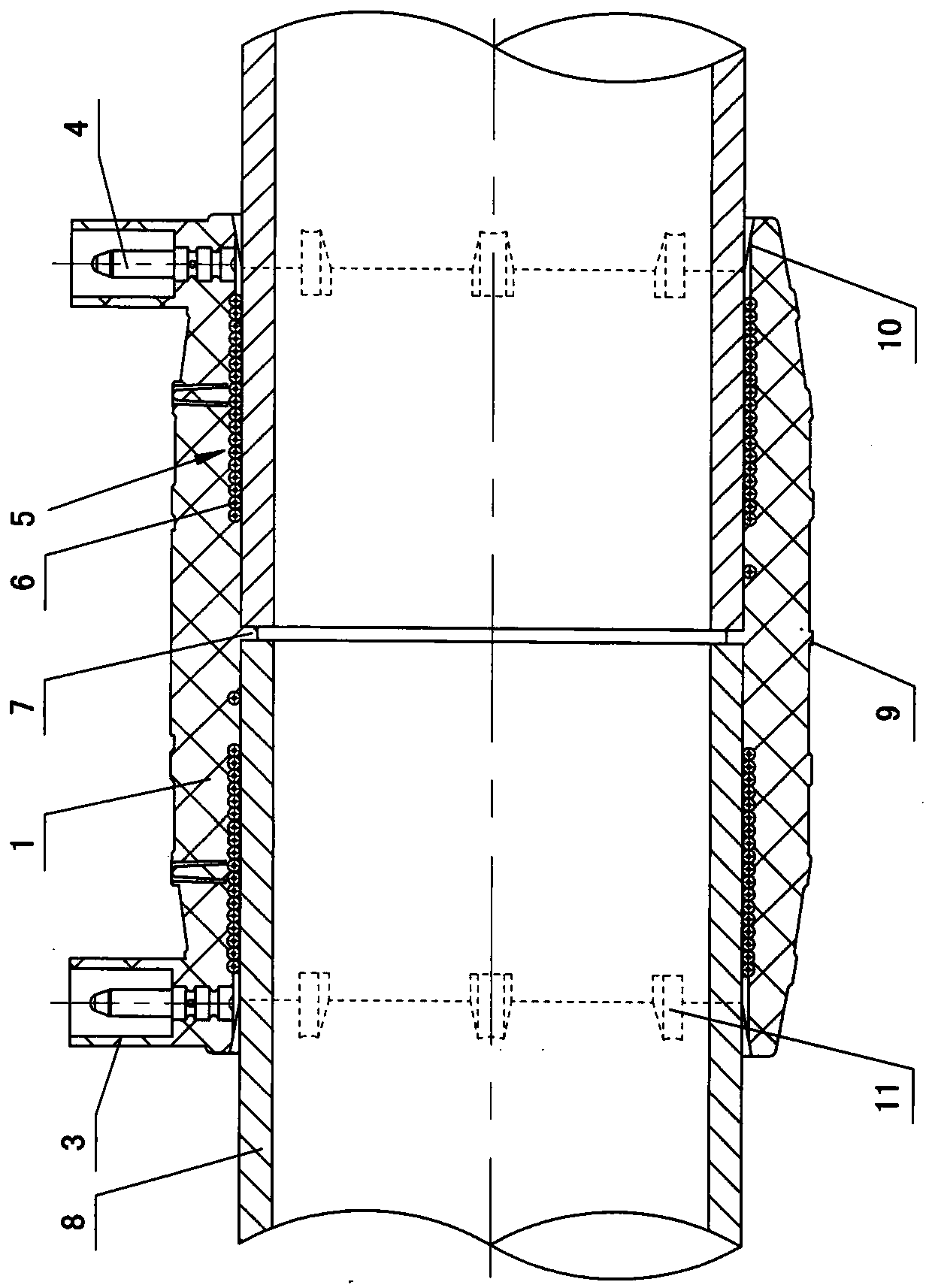

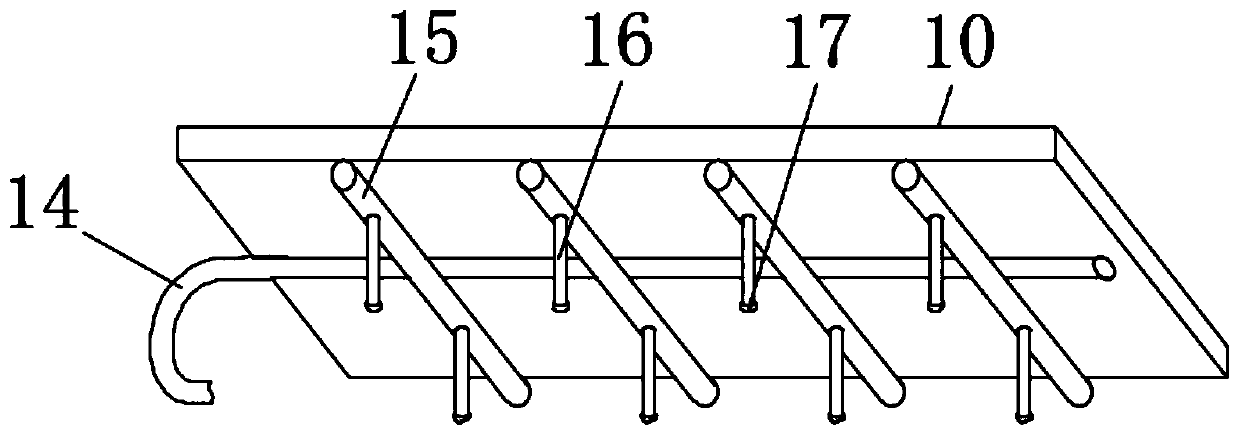

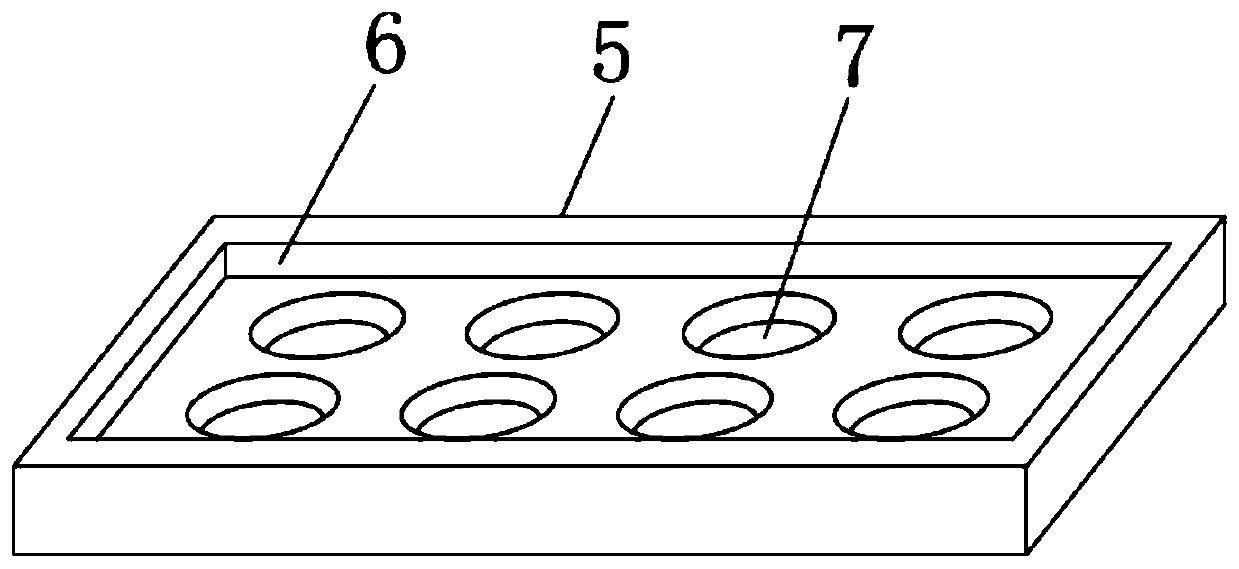

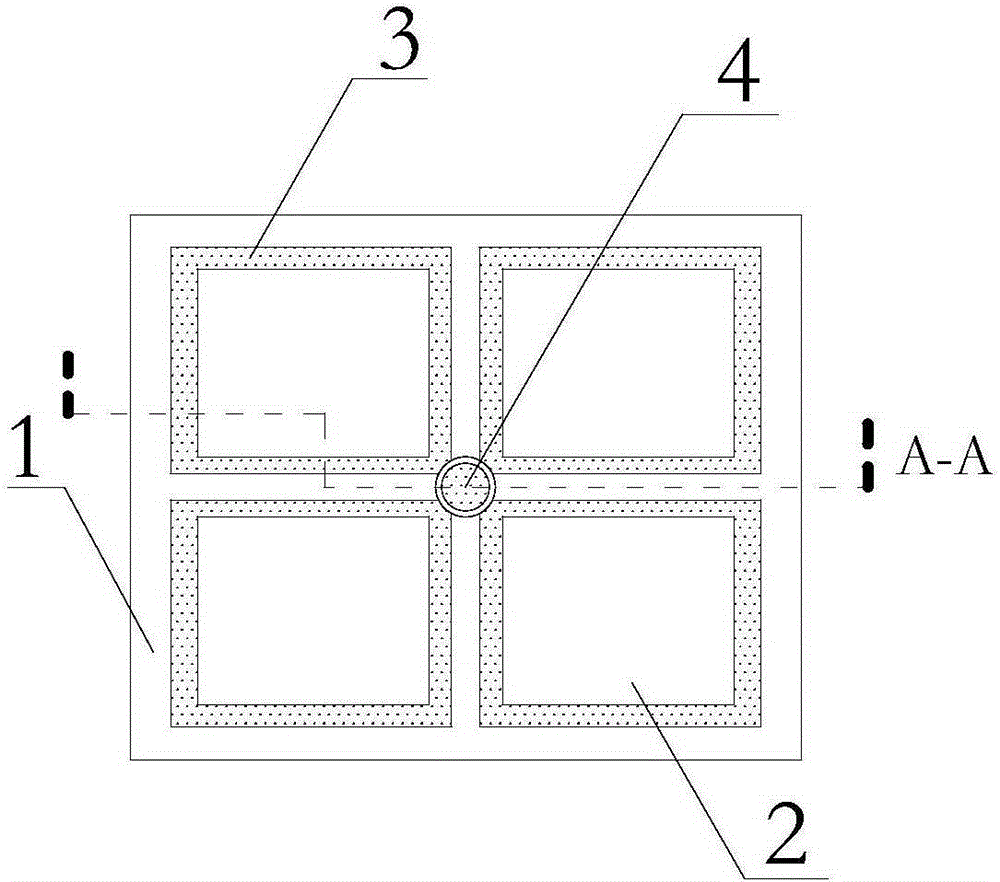

External display mark of polyethylene electro-fusion socket pipe fitting and limiting device for resistance wires

ActiveCN103968177AGuarantee welding qualityEasy to assemblePipe connection arrangementsPipe fittingArchitectural engineering

Owner:YONGGAO CO LTD

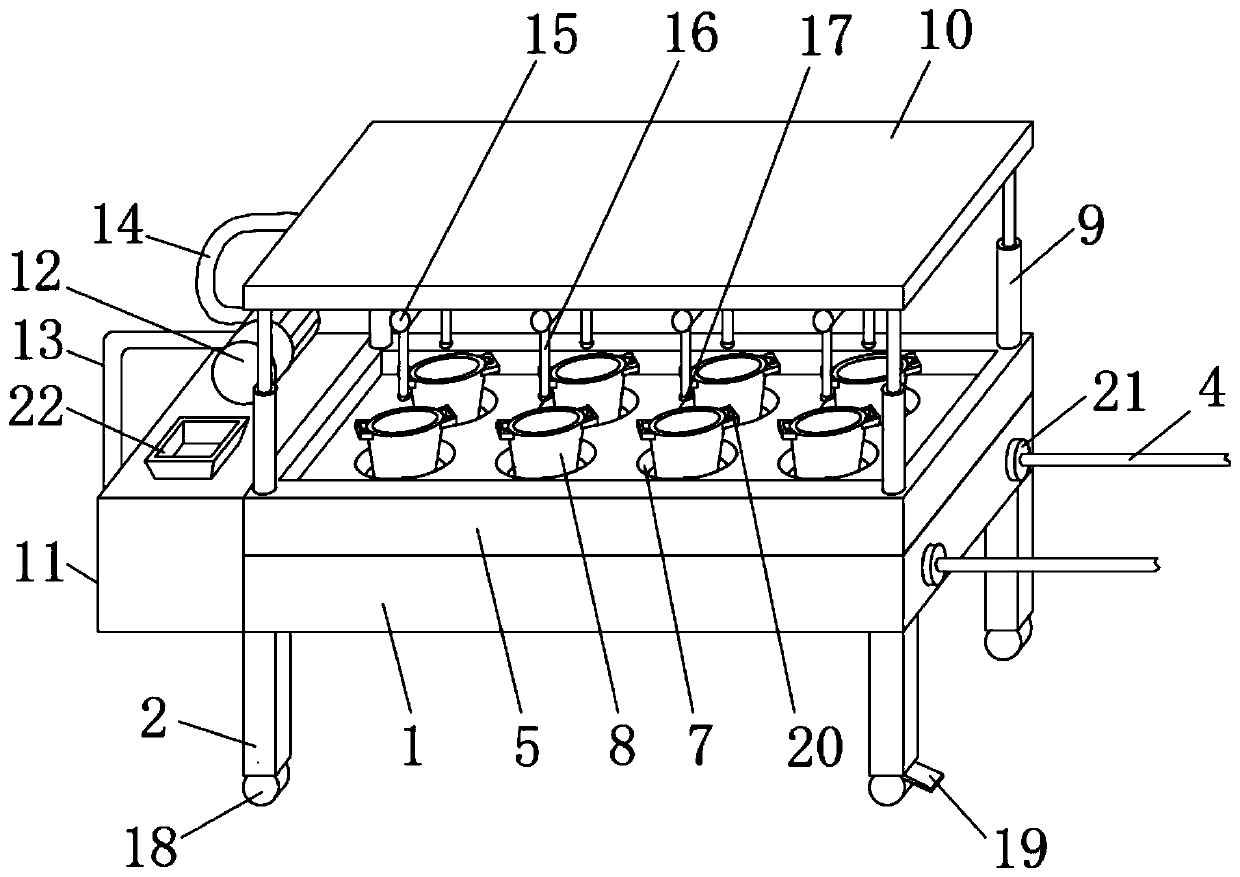

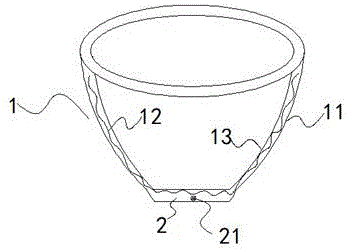

Planting device for potted strawberries

Owner:合肥市大邵生态农业有限公司

Protective film pasting equipment for aluminum profile

Owner:天津市众联铝业有限公司

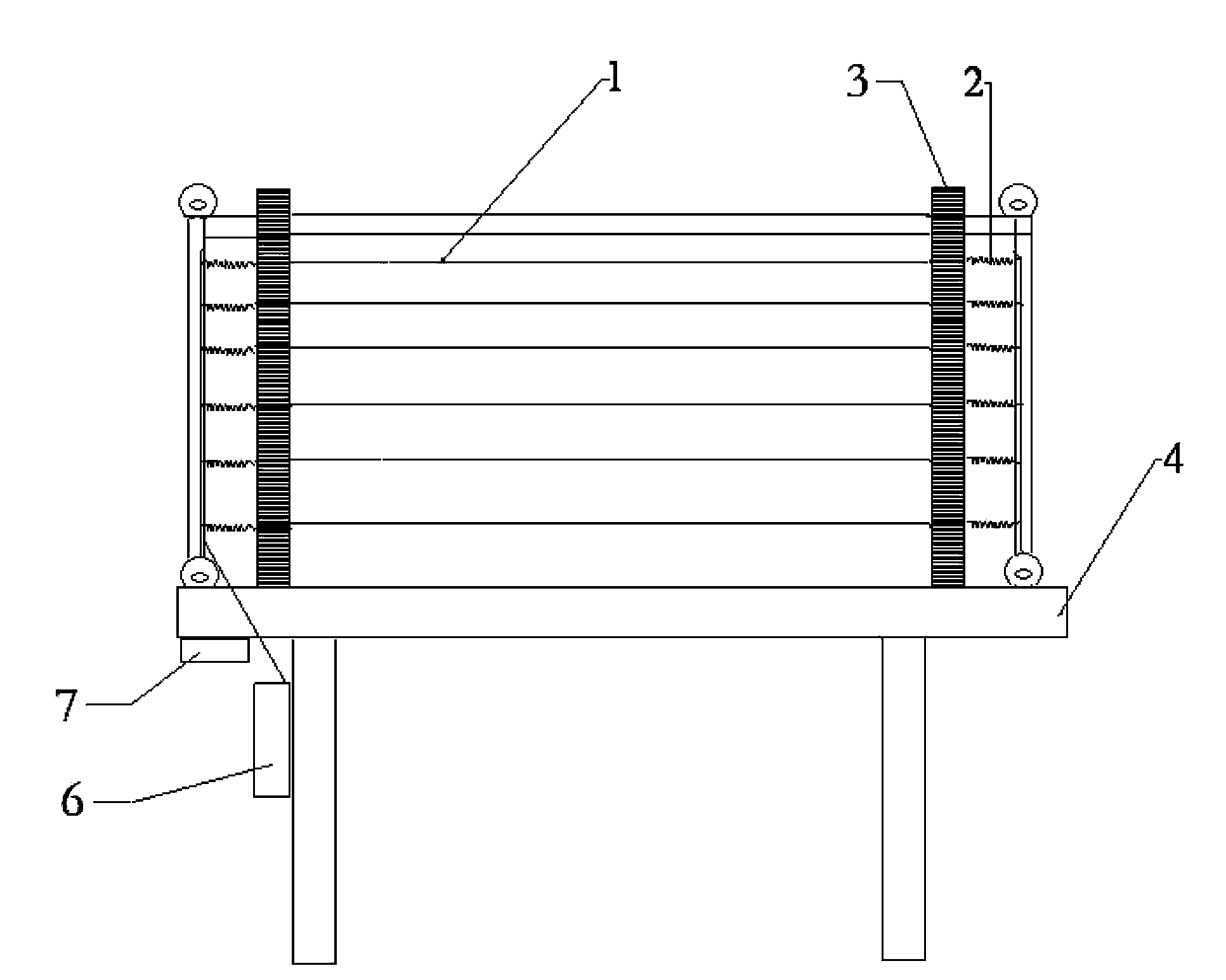

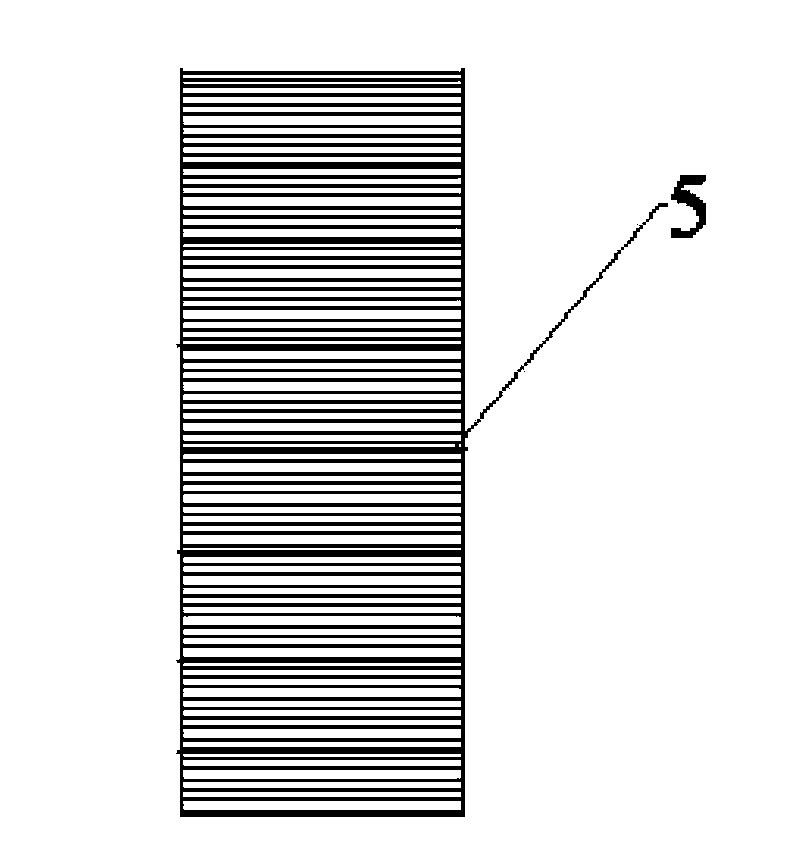

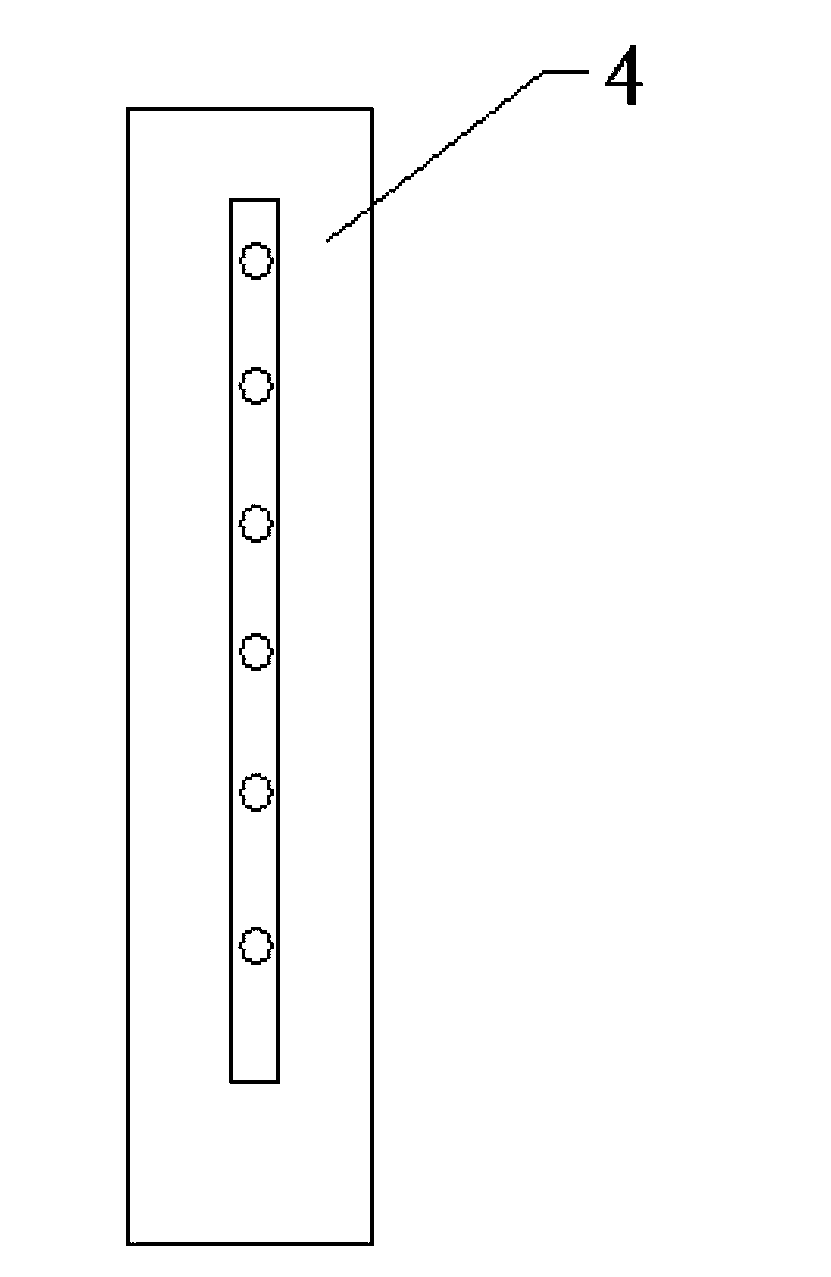

Foam sheet horizontal cutting device

Owner:ZHONGTIAN LIANHE ENERGY SAVING CONSTR DEV TIANJIN

Fermented soybean fermentation tank

Owner:CHONGQING YONGCHUAN FERMENTED SOY BEAN FOOD CO LTD

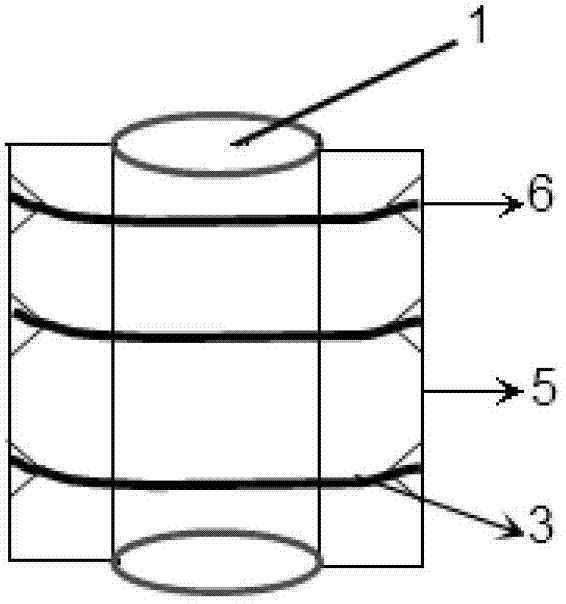

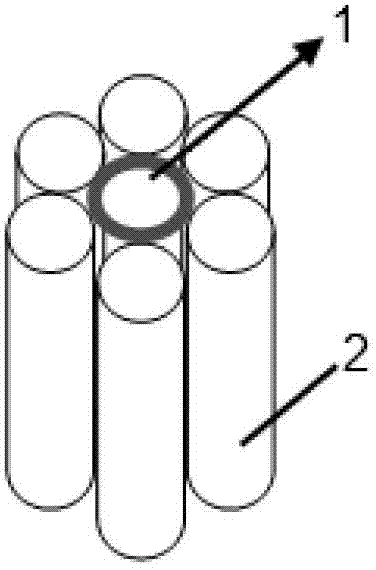

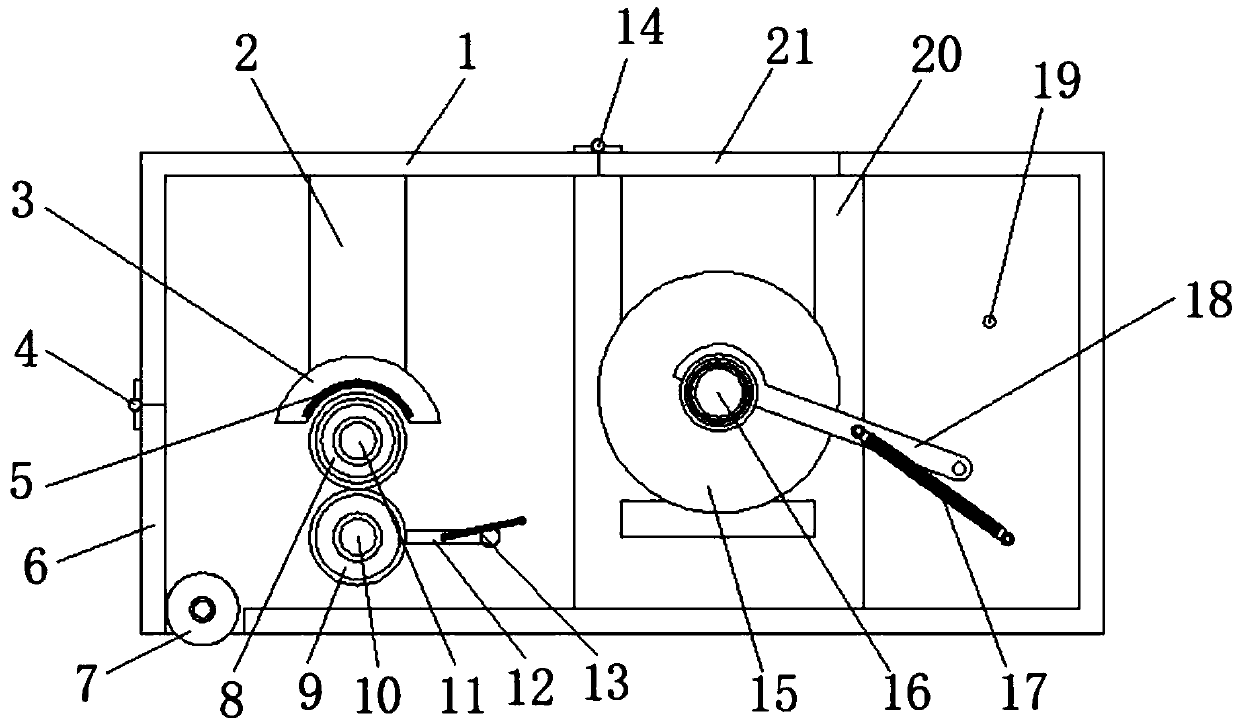

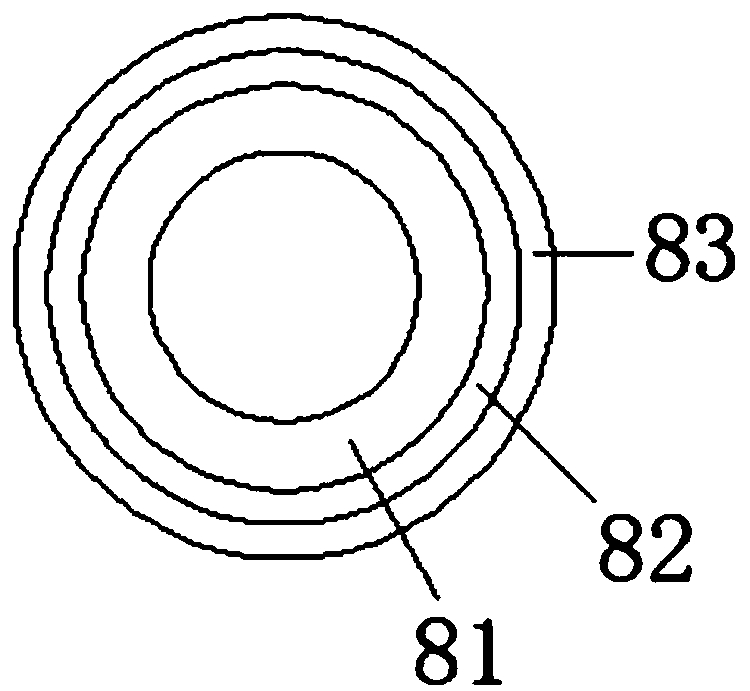

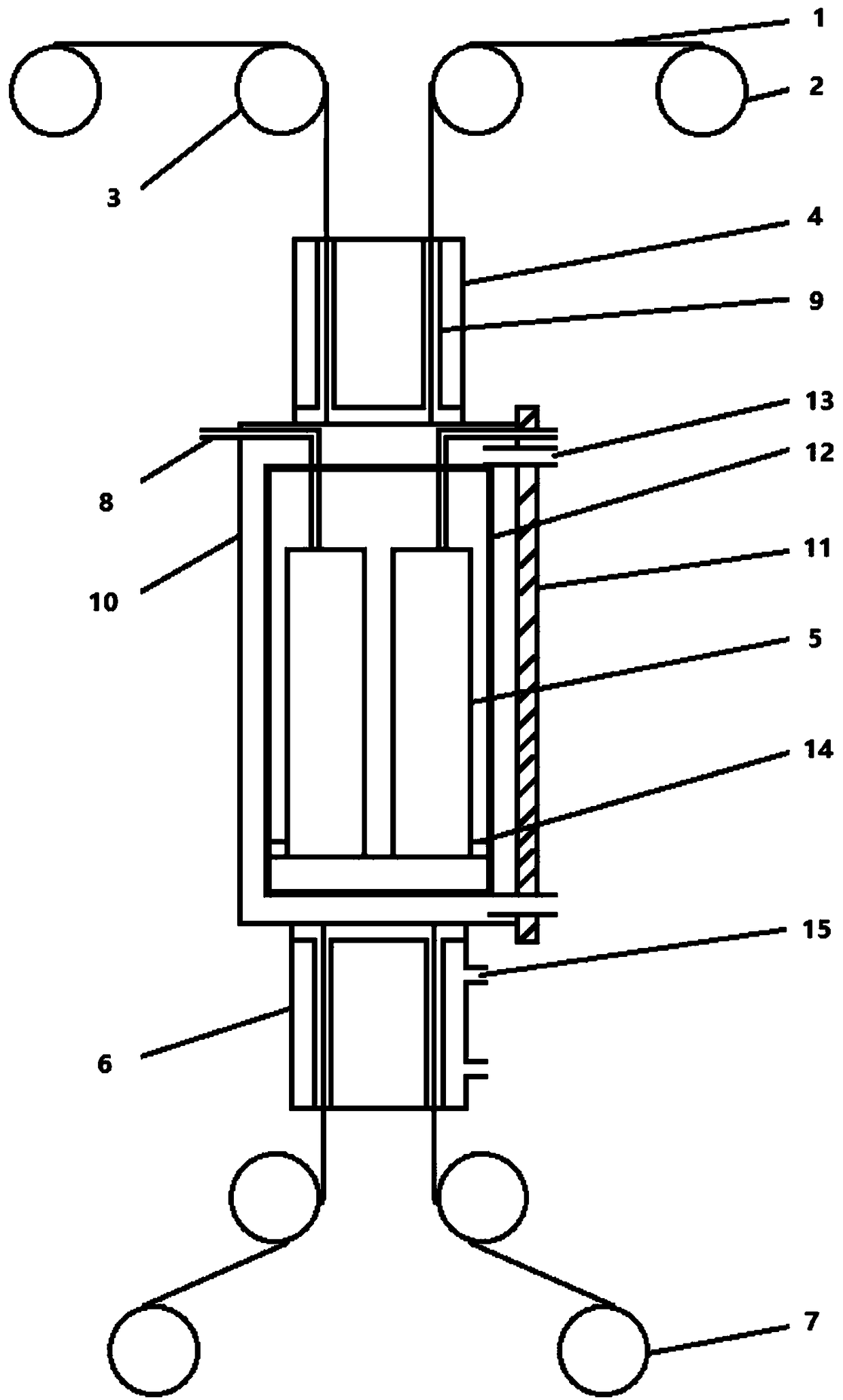

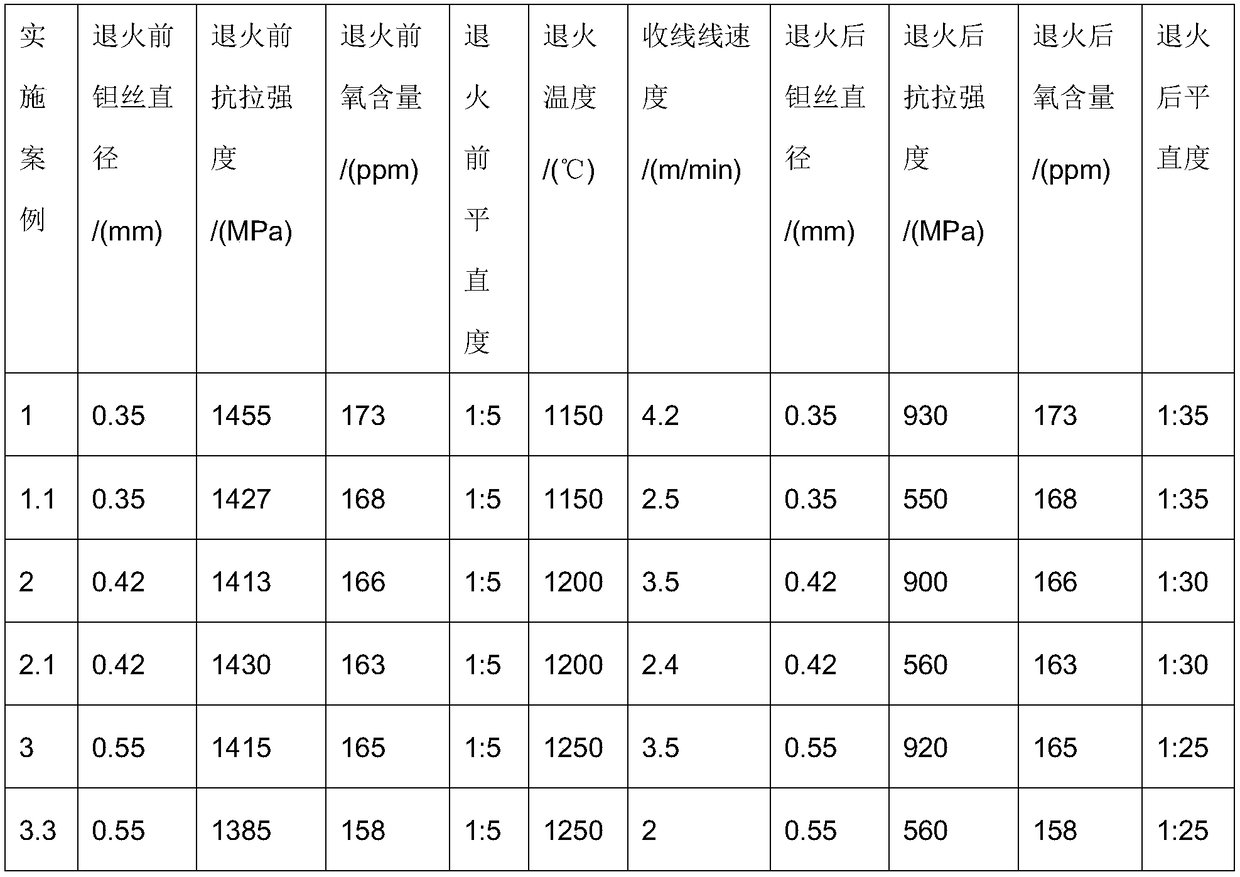

Device and method for manufacturing semi-hard or soft tantalum wire

ActiveCN109280762AGuaranteed not to be oxidizedIncrease productivityFurnace typesHeat treatment furnacesElectrical resistance and conductanceConductor Coil

Owner:江门富祥电子材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap