Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Textile dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing is the process of adding color to textile products like fibers, yarns, and fabrics. Dyeing is normally done in a special solution containing dyes and particular chemical material.

Bleaching and dyeing sewage treatment water purification agent

InactiveCN101177316ALow costSave waterWater/sewage treatment by flocculation/precipitationCalcium hydroxideAcid water

Owner:梁代福 +1

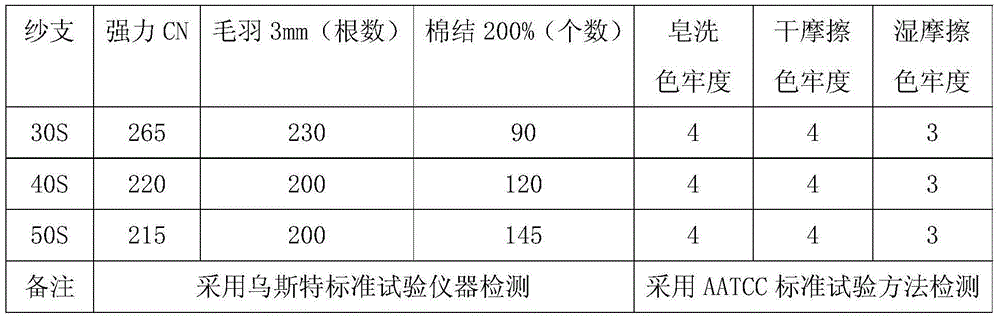

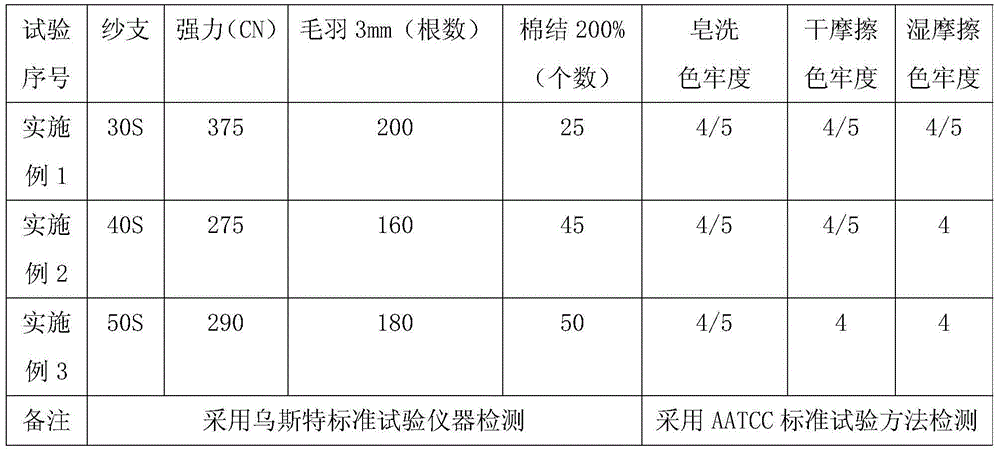

Pure cotton cheese dyeing method

Owner:LUTAI TEXTILE

Denim fabric printing and dyeing process

ActiveCN107254786AFast coloringNot easy to fadeLiquid/gas/vapor removalTextile treatment machine arrangementsSodium bicarbonateDenim

Owner:上海宛林服装有限公司

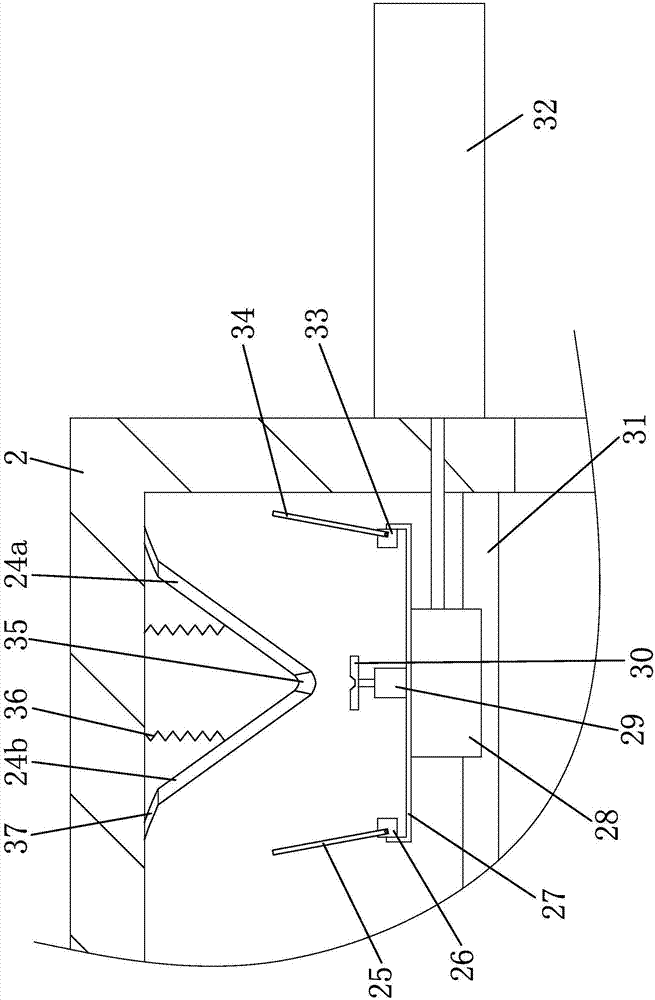

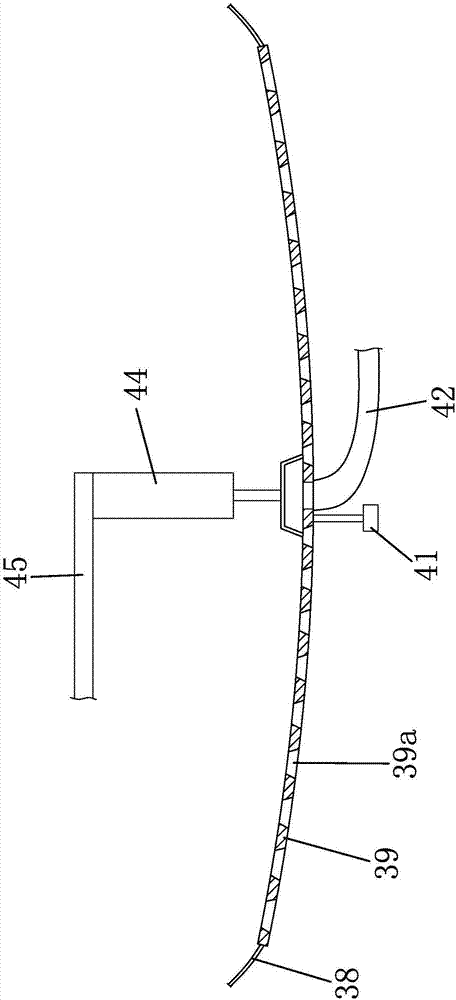

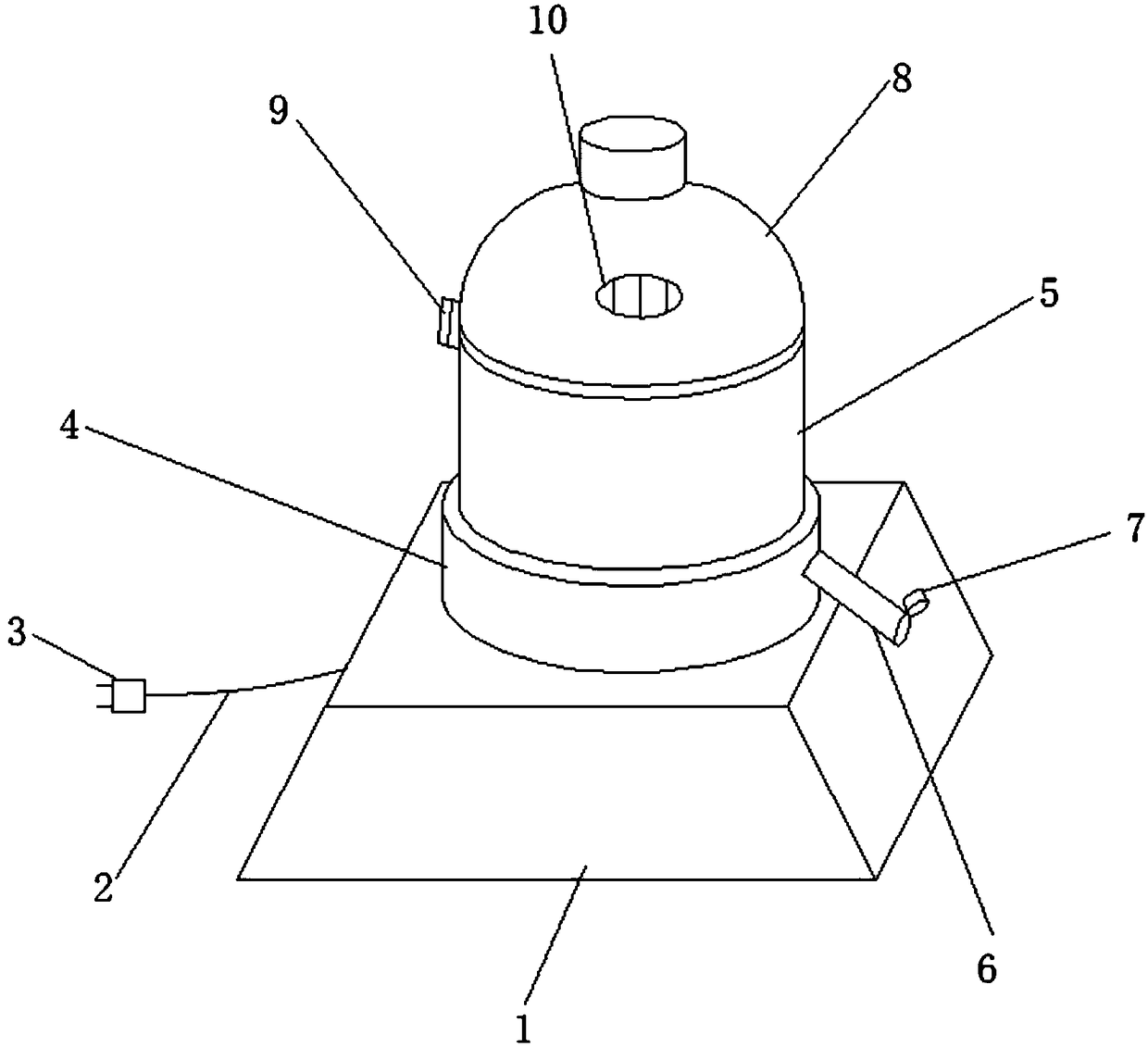

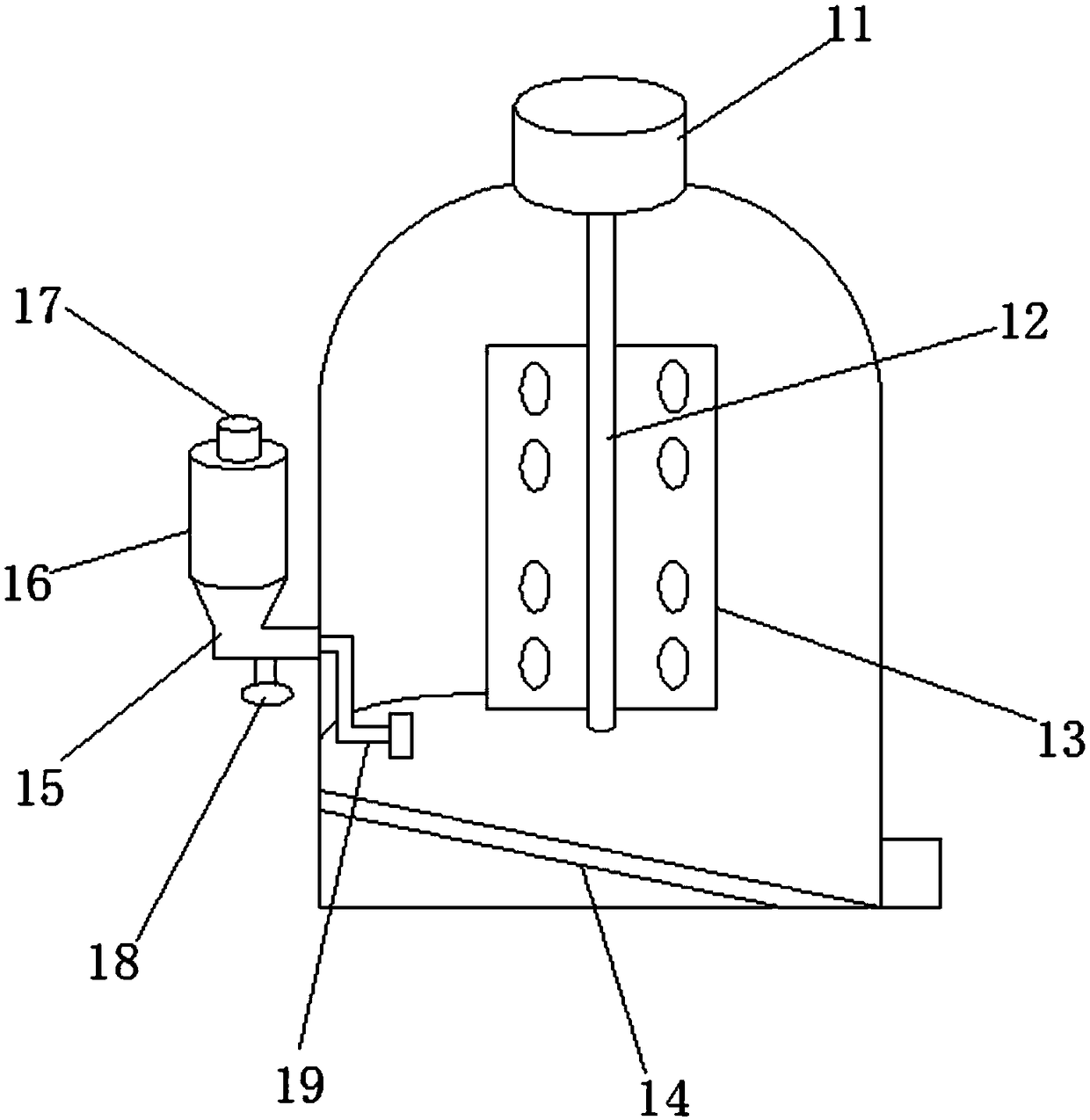

Full-automatic dye mixing device for printing and dyeing mill

InactiveCN108187531AHigh activityKeep aliveRotary stirring mixersTransportation and packagingEngineeringNitrogen gas

Owner:RIZHAO POLYTECHNIC

Yellow environment-friendly textile dye mixture

InactiveCN111004523AEnvironmentally friendly, safe and non-irritatingImprove performanceOrganic dyesOXALIC ACID DIHYDRATEMaterials science

The invention discloses a yellow environment-friendly textile dye mixture, and belongs to the technical field of textile dyes. The yellow environment-friendly textile dye mixture is prepared from 20 to 50 parts of a mineral dye, 30 to 40 parts of uranidin, 15 to 25 parts of 1-[(2-hydroxyethyl) amino]-4-(methylamino), 40 to 50 parts of Lffler's methylene blue, 20 to 30 parts of oxalic acid, 1 to 4parts of an auxiliary agent and 1 to 5 parts of butyl acrylate. The yellow environment-friendly textile dye mixture is prepared from the mineral dye, uranidin, 1-[(2-hydroxyethyl) amino]-4-(methylamino), Lffler's methylene blue, oxalic acid, auxiliaries and butyl acrylate according to a certain proportion, and has the advantages of being environmentally friendly, safe, free of stimulation, friendly to the environment, excellent in performance, uniform in dyeing, resistant to washing and the like.

Owner:XIANGYANG XINZHENG TEXTILE

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap