Improved microwave sulfur lamp

A sulfur lamp and microwave technology, which is applied in the field of lighting equipment, can solve the problems of affecting the use effect of microwave sulfur lamps, damaging the magnetron, and long lighting time, so as to improve the problem of one-time lighting failure, improve work performance and use effect ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

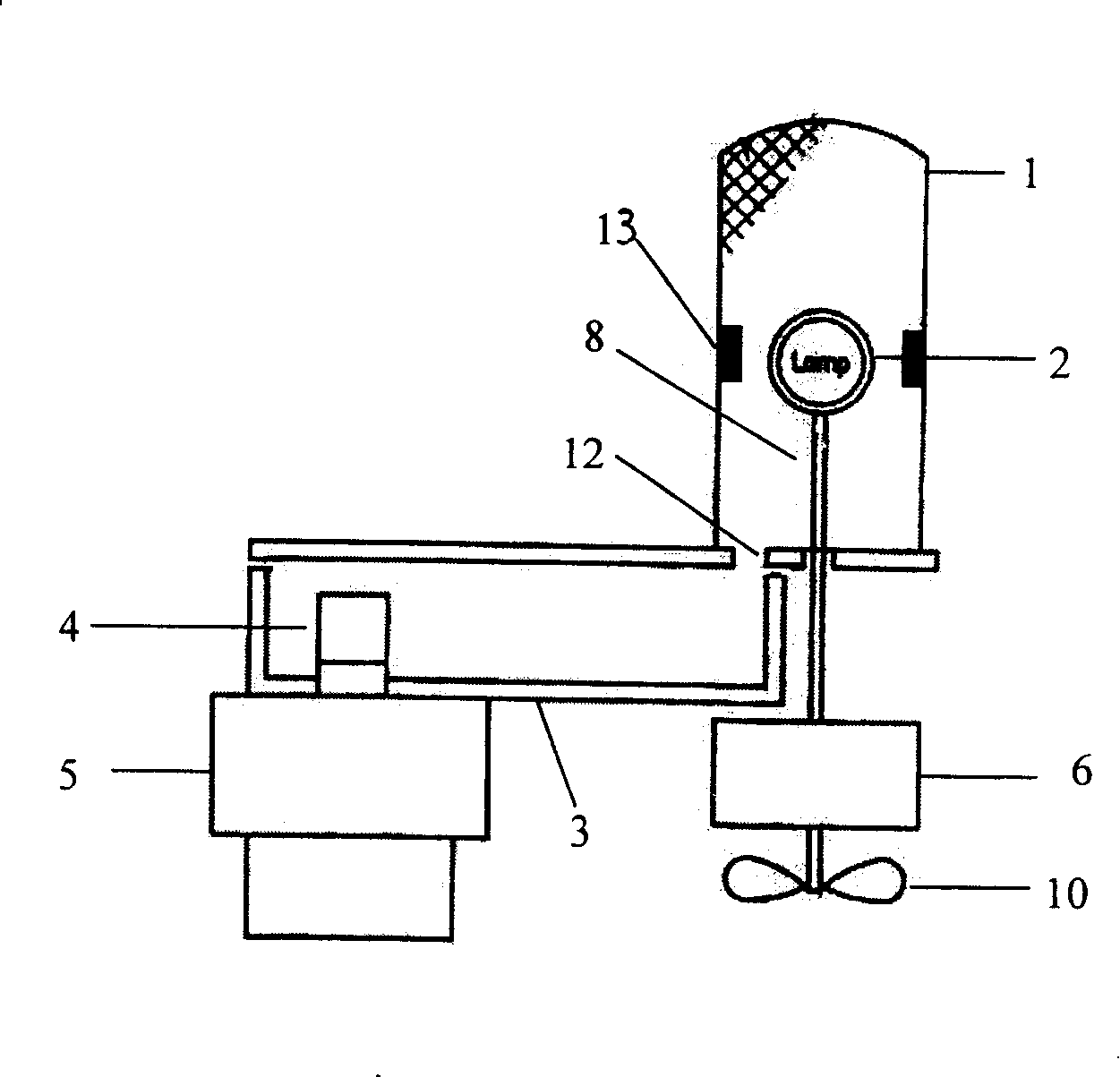

[0026] The preparation method of the microwave sulfur lamp in the embodiment of the present invention is the same as the preparation method of the existing microwave sulfur lamp, so it will not be repeated here. The improvement is that there are two corresponding antenna feed structures on the inner wall of the resonant cavity. The antenna feed structure uses a shaping die to stamp the aluminum into a needle-shaped body with a radius of 1mm and a length of 1mm, and then Welding is fixed on the inner wall of the resonant cavity corresponding to the horizontal position of the center of the bulb.

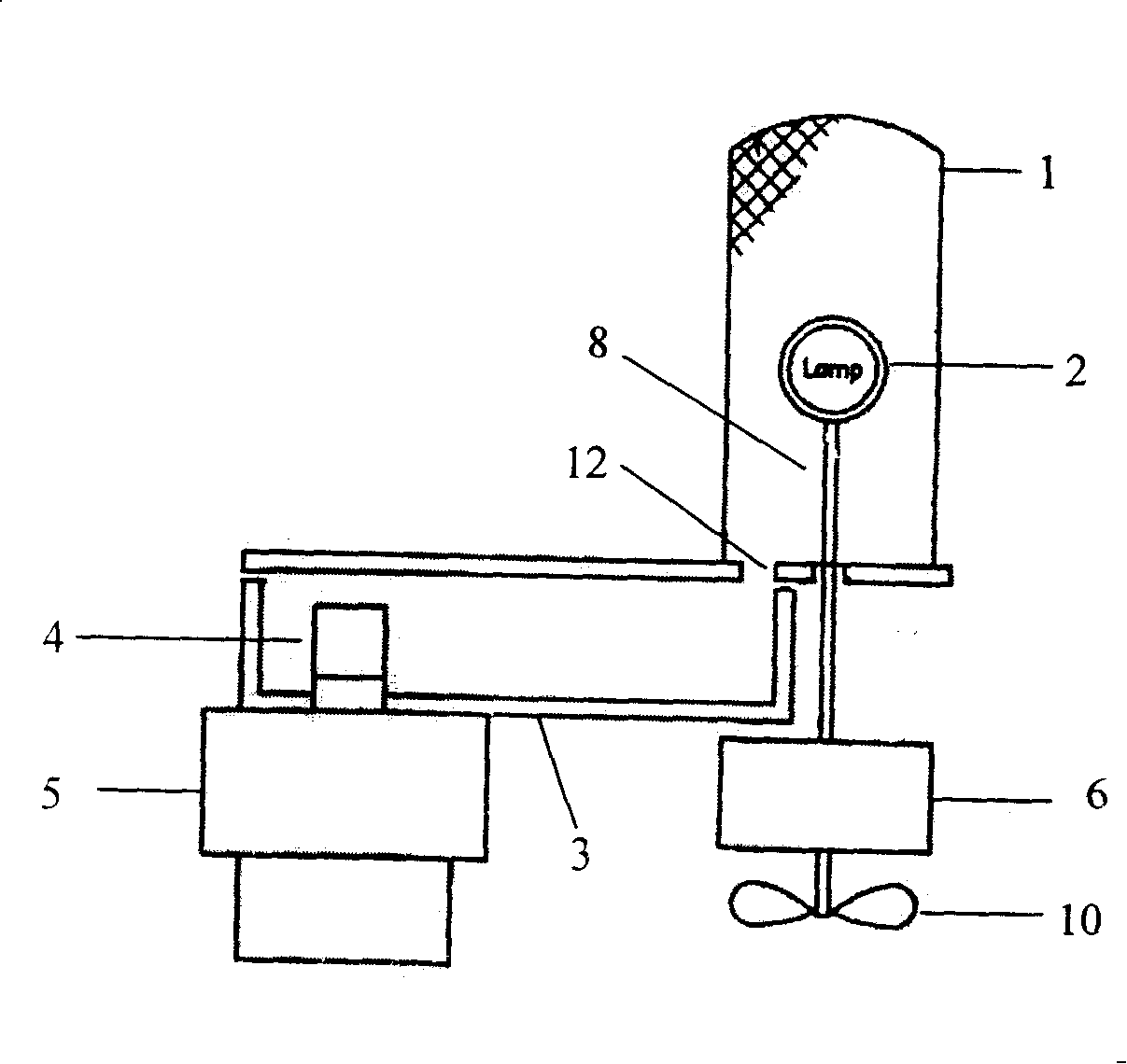

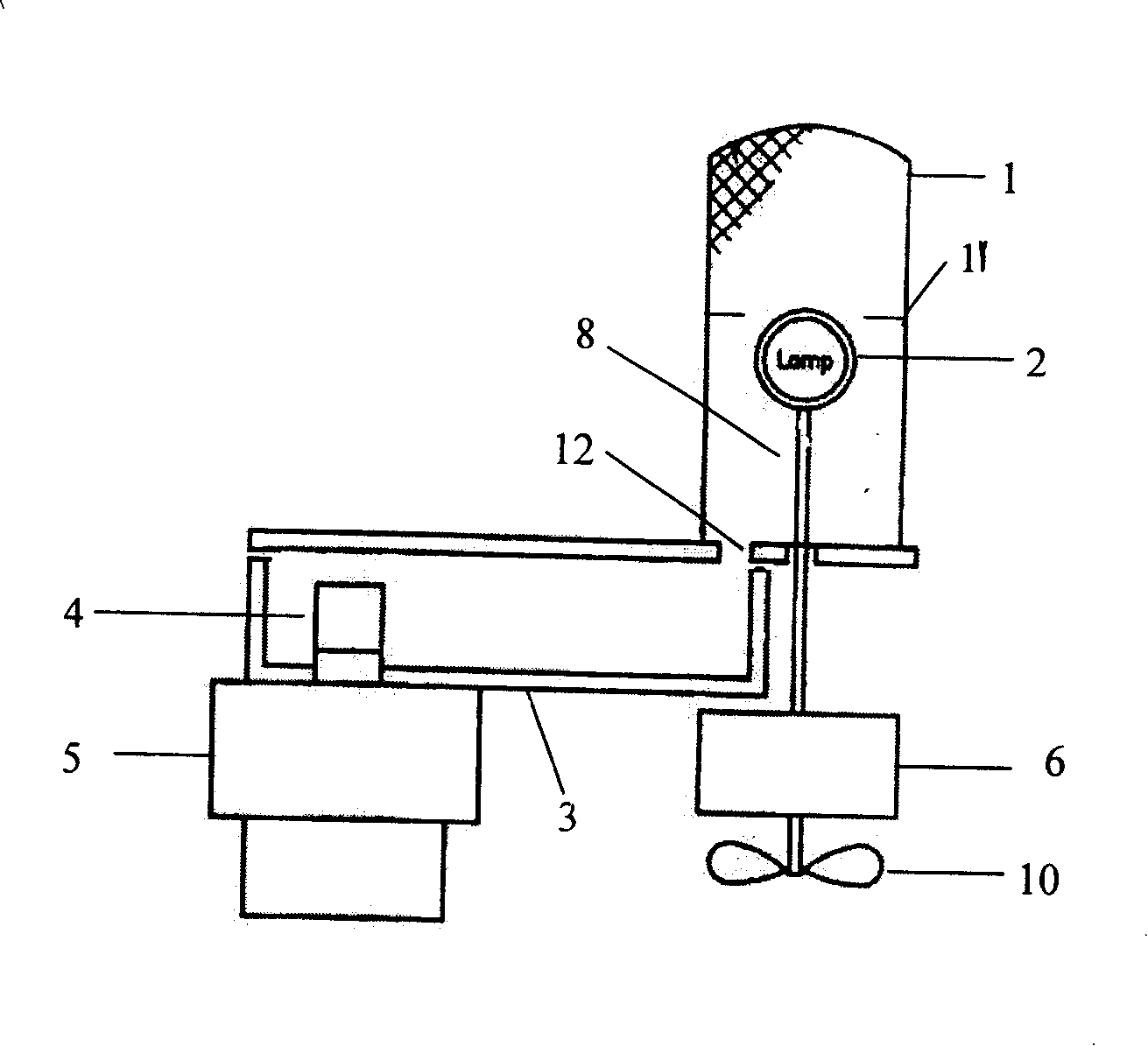

[0027] When the improved microwave sulfur lamp of the present invention works, its work process is identical with the work process of existing microwave sulfur lamp (as figure 1 As shown), when the power is turned on, the bulb 2 set in the resonant cavity 1 is driven by the motor 6 through the lamp handle 8 to rotate, and the microwave energy emitted by the magnetron 5 is transmitted by t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap