Device for producing copper anode plate and method thereof

A copper anode plate and spray device technology, applied in pig iron foundry, process efficiency improvement, photography process and other directions, can solve the problems of high labor intensity, large investment, inconvenient production, etc., and achieve simple installation and labor. Low strength, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

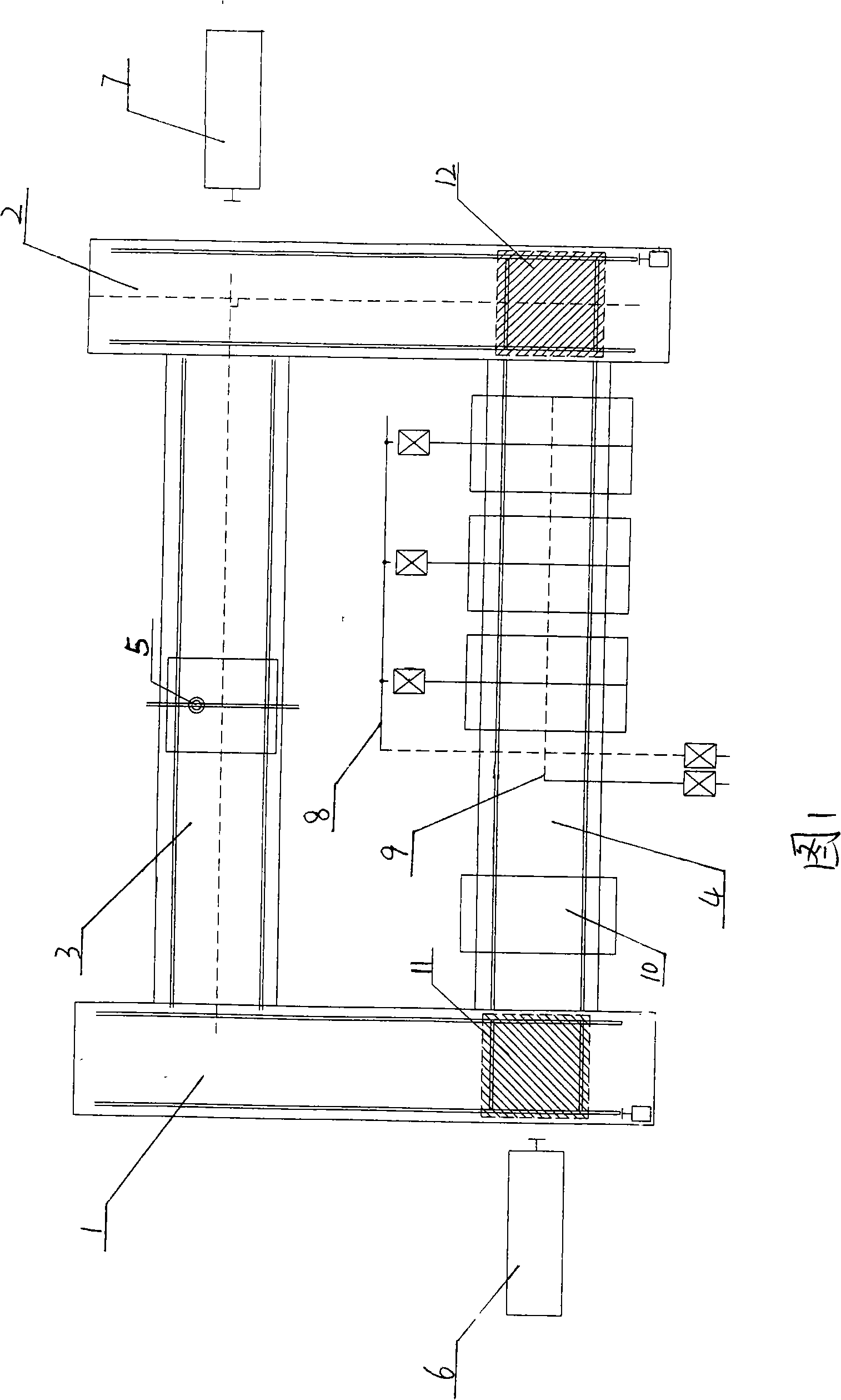

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Two parallel longitudinal rails 1 and 2 are arranged, and two front and rear transverse rails 3 and 4 are arranged between the two longitudinal rails 1 and 2. The height of the longitudinal rails 1 and 2 is lower than the transverse rails 3 and 4. Movable trailers 11 and 12 are arranged on the rails 1 and 2, and a carriage is installed on the trailer, and the carriage is provided with a joint track which is in the same direction as the transverse rail and is flush with it; The right side of a transverse track 3 is respectively provided with a push cylinder 6,7. Copper water pouring ladles 10 and cold water spraying devices 8 are installed sequentially from left to right on the top of the latter horizontal track 4, and a spraying device 9 for spraying water upwards is installed below, and pouring templates are sequentially arranged on the latter horizontal track 4,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap