Method for preparing shadow mask type plasma display device front substrate medium layer

A plasma display and substrate medium technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of yellowing and high production cost, achieve yellowing reduction, lower production cost, high durability The effect of pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

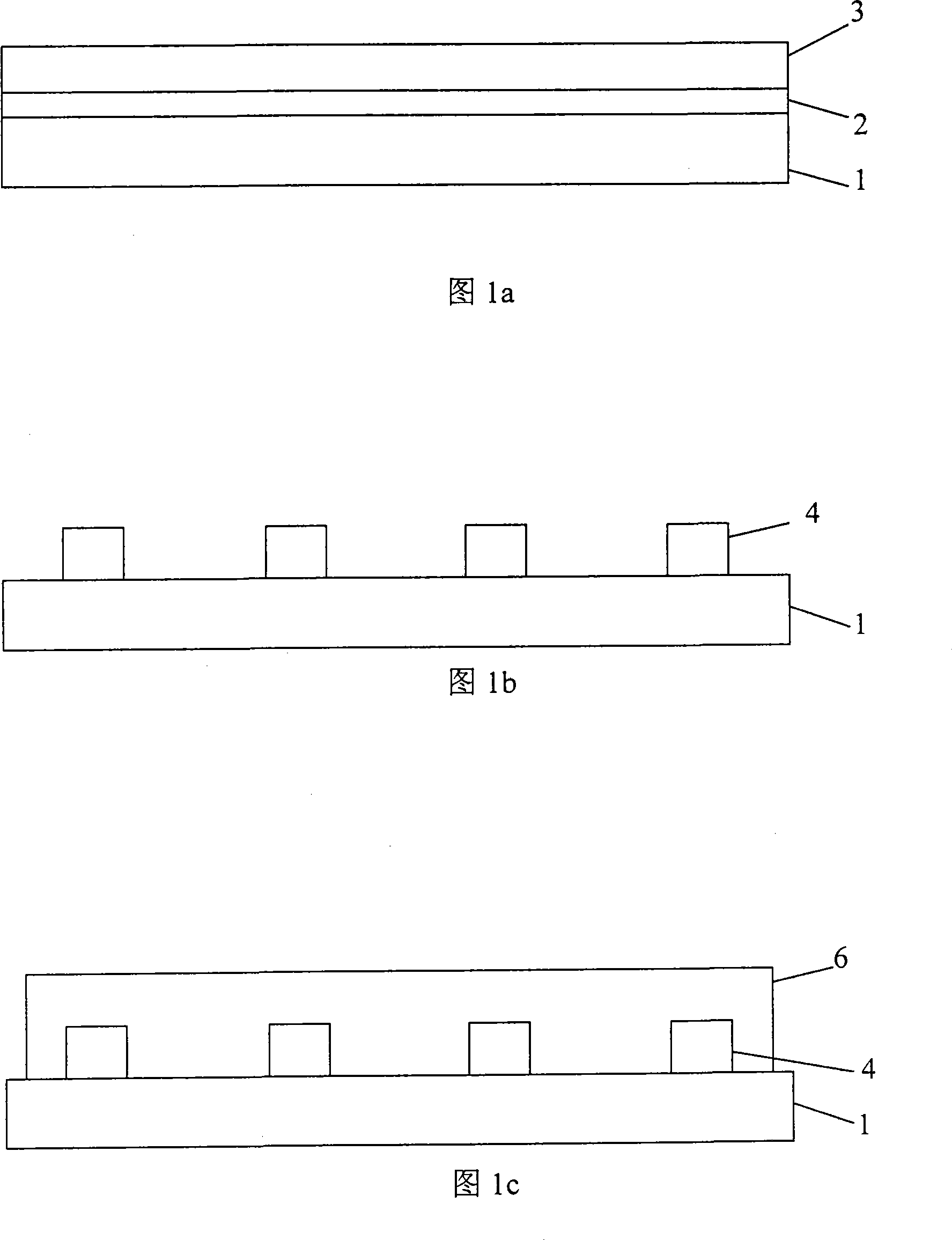

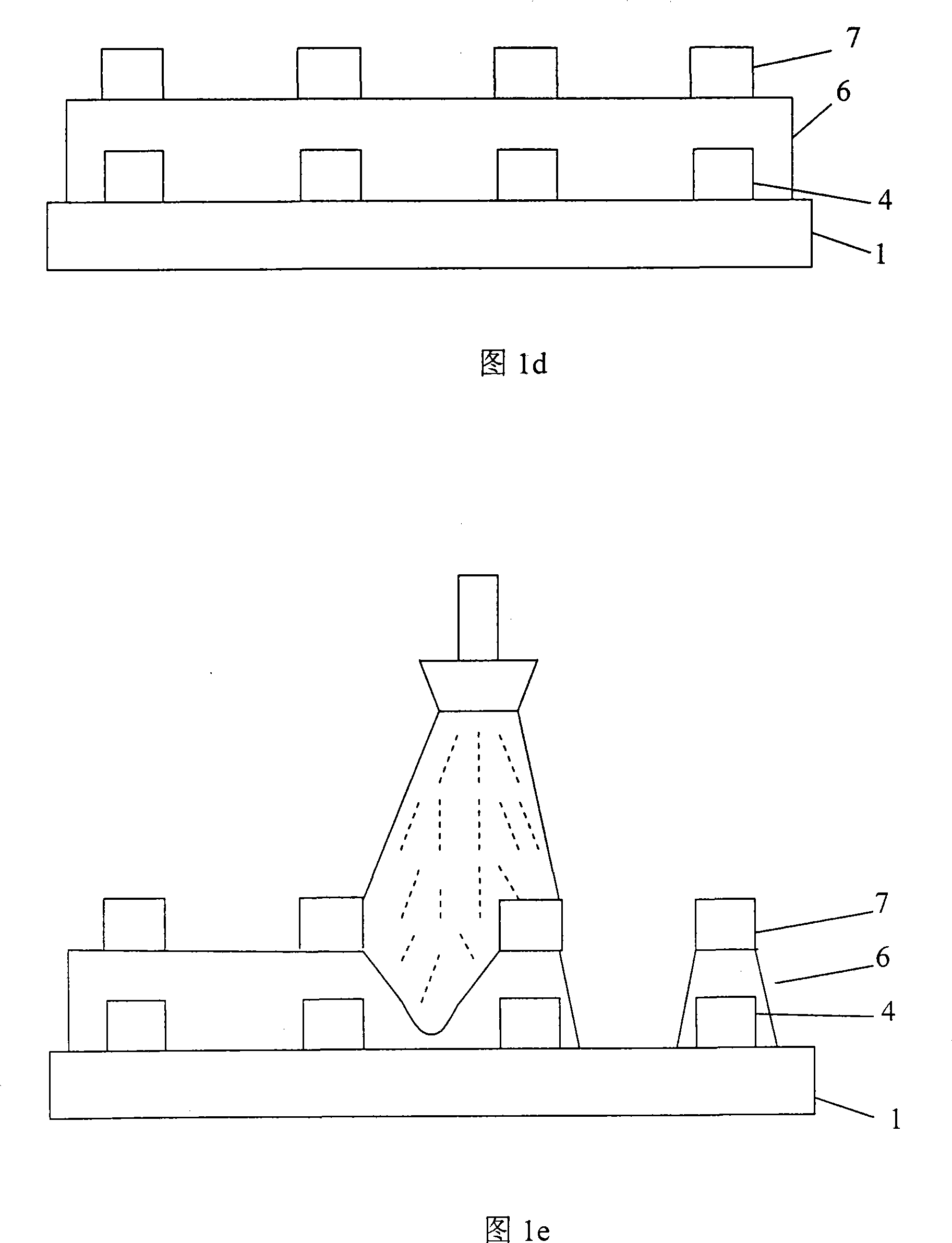

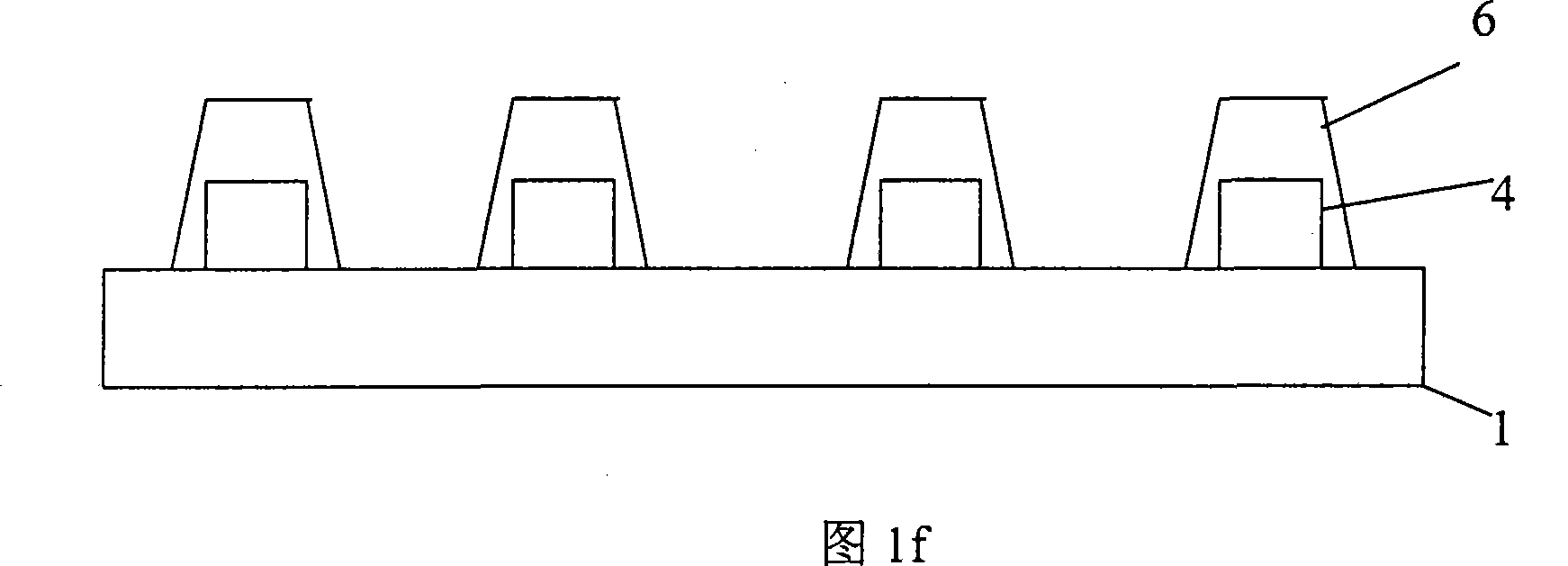

[0031] Such as figure 1 Shown, the shadow mask type plasma display front substrate dielectric layer manufacturing method of the present invention, it comprises the following steps:

[0032] (a). Clean the glass substrate 1, stir the glass paste 2 and the photosensitive silver paste 3 at high speed to defoam, cool to room temperature for use, and the glass substrate 1 is ordinary soda-lime glass;

[0033] (b). On the glass substrate 1, evenly coat the glass paste 2 with a thickness of 8-15 μm, then place it on a flat table and level it for 10-20 minutes to make the thickness of the glass paste 2 on the surface of the glass substrate 1 uniform, and bake Dry glass paste 2 volatilizes the low melting point solvent in the paste;

[0034] (c). Coat the photosensitive silver paste (3) with a thickness of 15-24 μm on the upper surface of the glass substrate 1 wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap