Light-emitting diode (LED) and method for preparing LED and base of LED

A technology of light-emitting diodes and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problem that Kina diodes are easy to generate holes, damage the reliability of light-emitting diodes, and the Kina diodes cannot be small. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

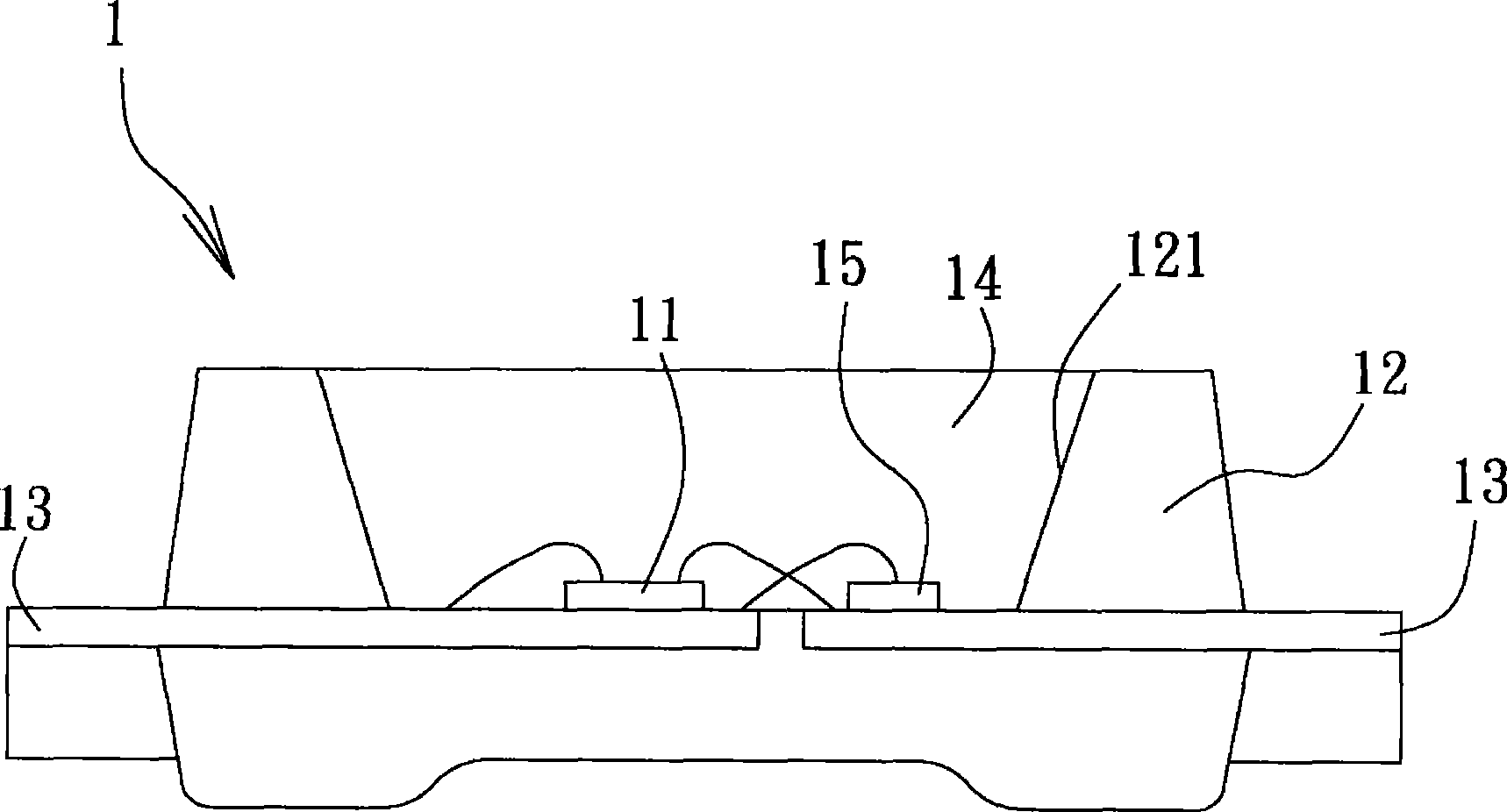

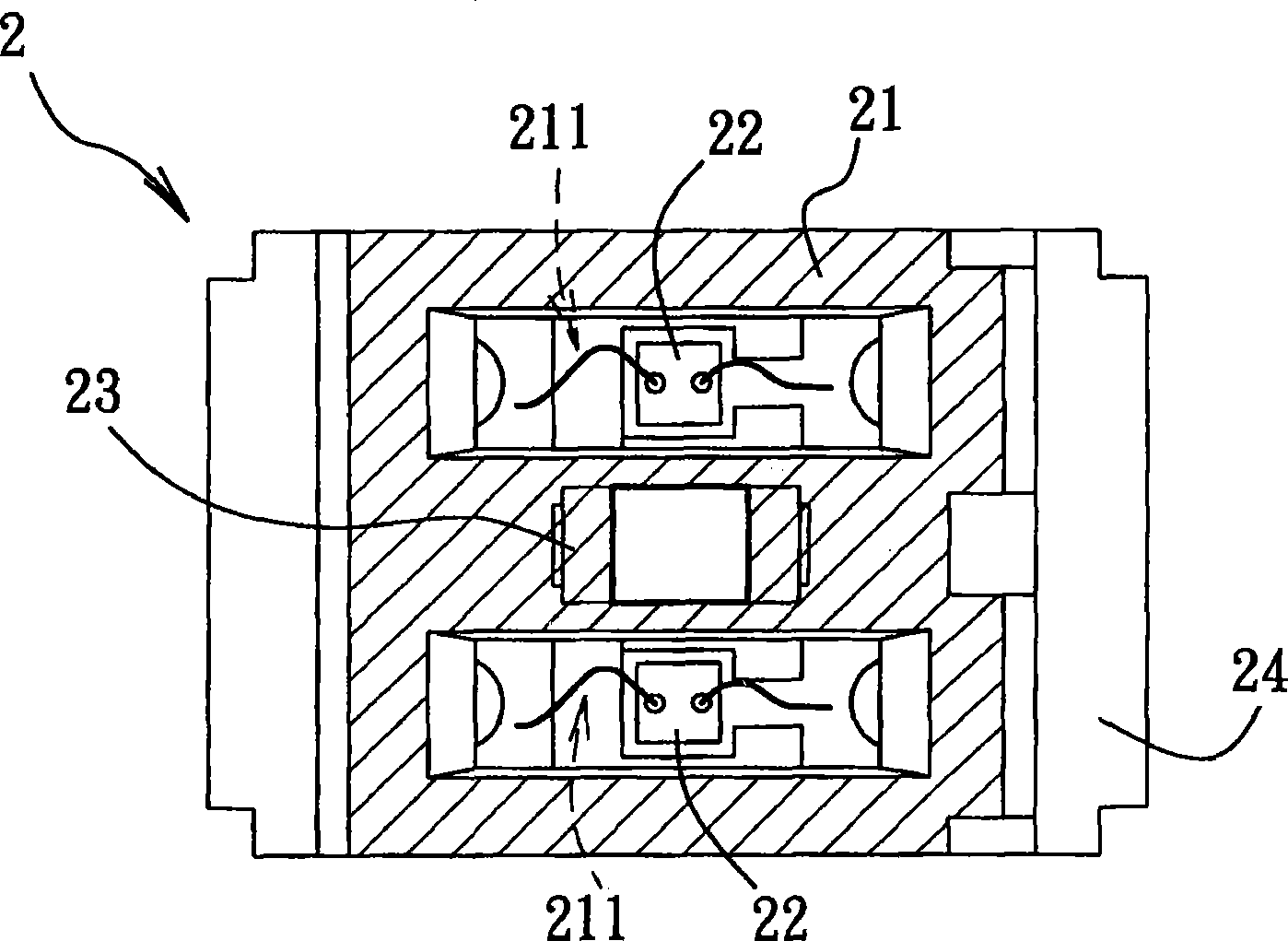

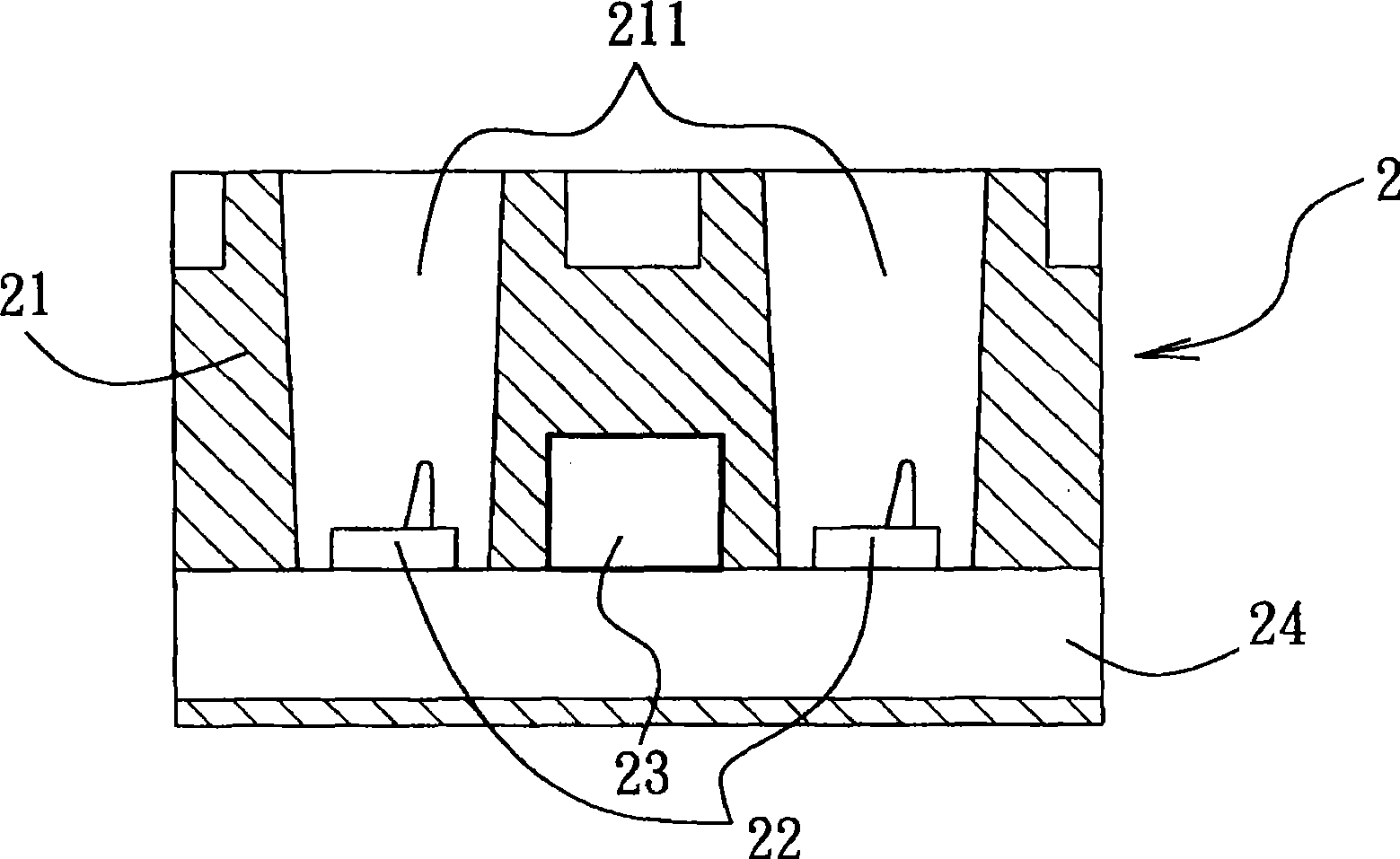

[0031] refer to Figure 4 and Figure 5 , The first preferred embodiment of the light emitting diode 3 and its manufacturing method of the present invention includes a base 4 , a crystal grain 5 and a transparent colloid 6 . The base 4 includes a plastic base 41 , a metal bracket 42 , a Zener diode 43 , a wire 44 and a covering glue 45 .

[0032] The plastic base 41 has a bottom wall 412 and a ring wall 413 defining a groove 411. The material is opaque and highly reflective. In this embodiment, the plastic base 41 is made of white thermoset type resin (by injection molding or compression molding). The metal bracket 42 has two legs 421, 422 spaced apart from each other, accommodated in the plastic base 41 and partly exposed from the plastic base 41, one end of each of the legs 421, 422 is exposed on the bottom wall 412, and the other end extends horizo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap