Conveying device

A technology of conveying equipment and vehicle frame, which is applied in the field of mechanized conveying equipment in the assembly line of automobile assembly workshops. It can solve the problems of unsuccessful transfer, lower production efficiency, and poor commonality, so as to reduce production costs and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

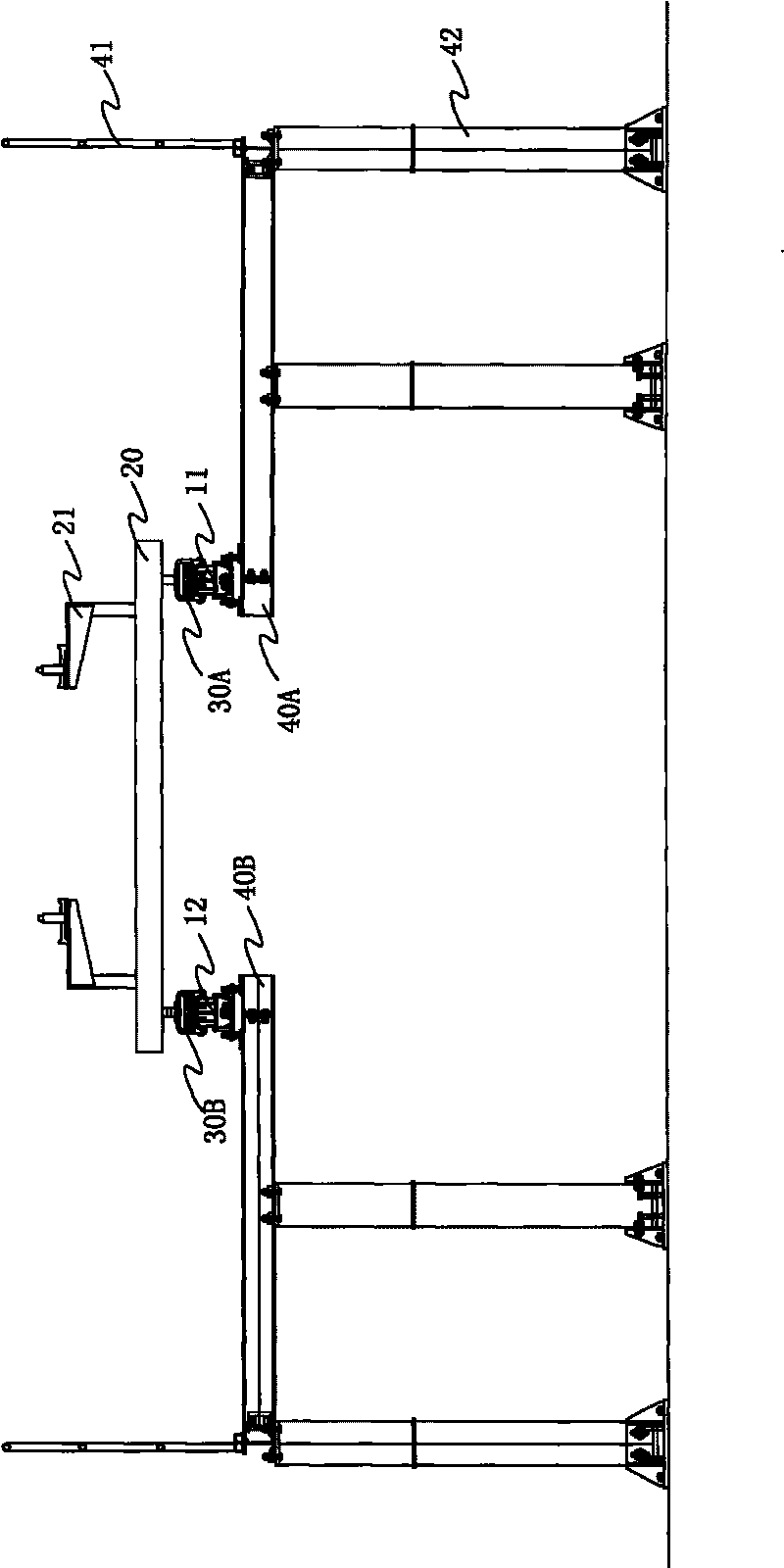

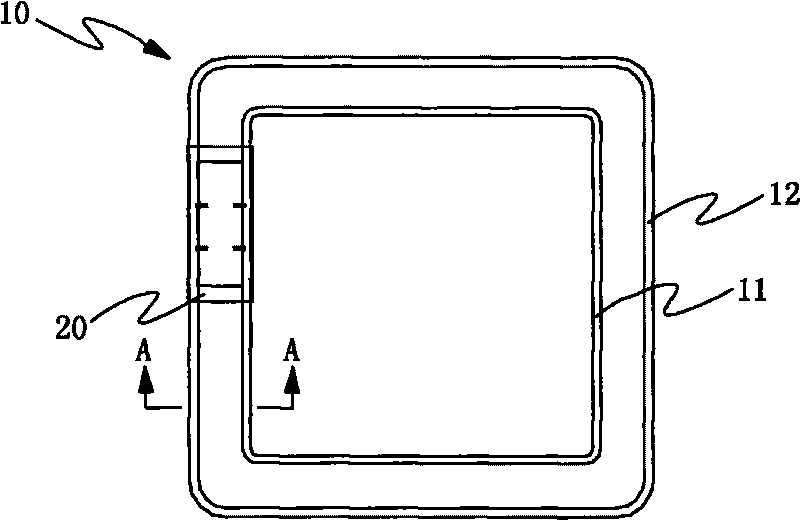

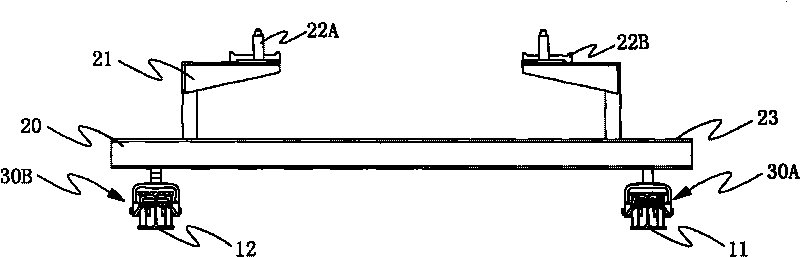

[0021] Such as figure 1 , figure 2 , image 3 The conveying equipment shown includes a guide rail 10 and a vehicle frame 20. The vehicle frame 20 is provided with a traveling mechanism to form a rolling fit with the guide rail 10. The vehicle frame 20 is powered by a driving device to walk in the direction defined by the guide rail 10. The guide rail 10 consists of two mutually parallel and closed orbits.

[0022] The guide rail 10 is ring-shaped, including inner and outer rails 11, 12, the straight sections of the inner and outer rails 11, 12 are parallel to each other, there are circular arc segments at the four corners for smooth transition and the circular arc segments are concentric arcs, and the inner and outer rails 11, 12 are parallel to each other. The rails 11 and 12 are respectively surrounded by two H-shaped steels with the same cross-section in a way that thei

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap