Method for protecting overheat of series reactor and overcurrent of capacitor

A series reactor and overcurrent protection technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of large discreteness, insulation burnout, and unsatisfactory protection of capacitor banks by fuses, and achieve simple and easy use The effect of mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

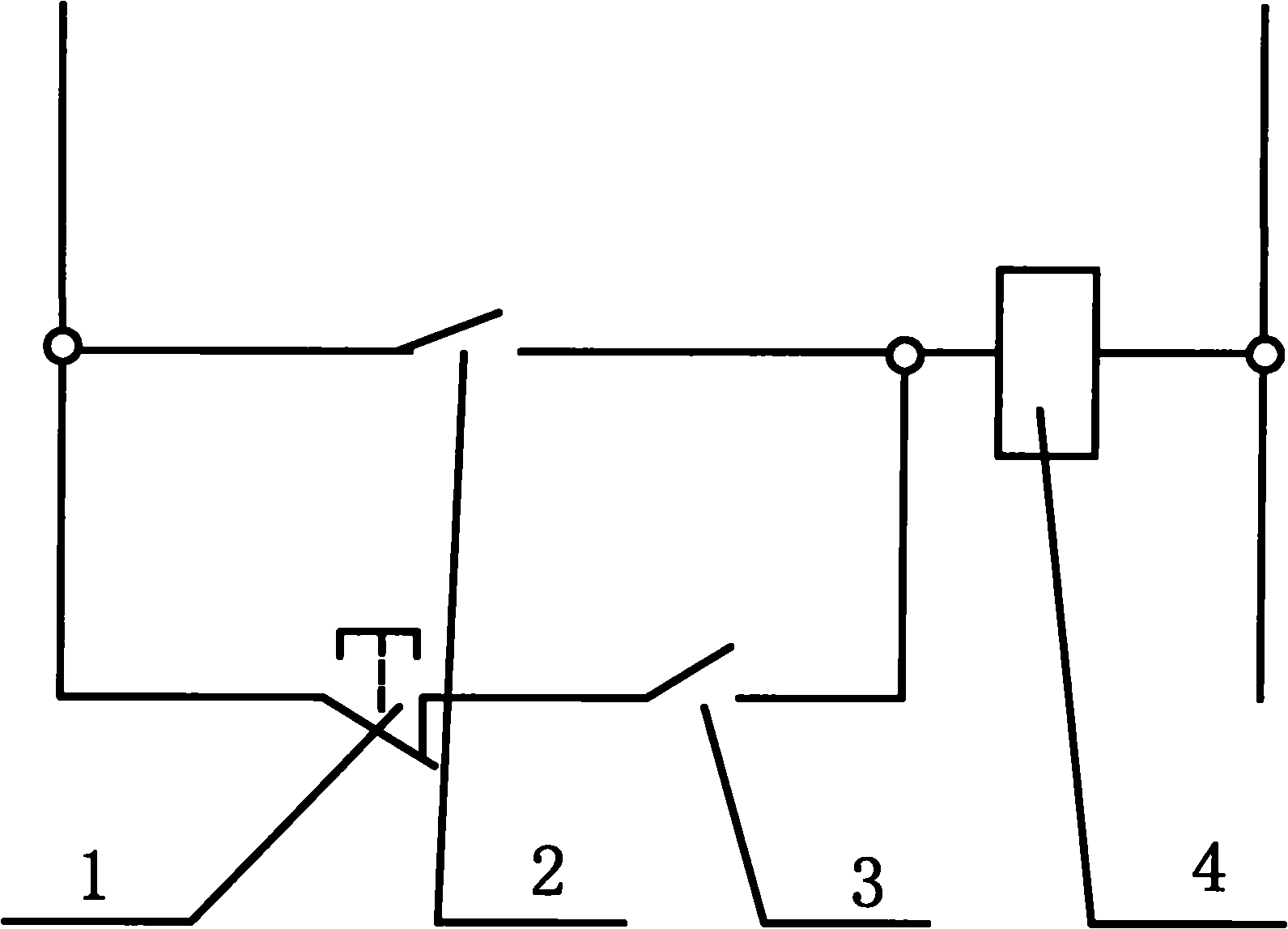

Embodiment 1

[0016] The method of protecting the overheating of the series reactor and also serving as the overcurrent protection of the capacitor is to install a temperature switch on the reactor by controlling the temperature rise of the reactor, and limit the overcurrent current of the capacitor by controlling the range of the temperature rise of the reactor. The normally open contact KSD of the device temperature switch is connected in series with the coil wire of the relay KA, the relay KA is connected in series with the normally closed button and the contact wire, and the normally open contact KSD is connected with the normally closed button and the contact wire In parallel, the normally closed button is connected in series with the contact wire.

Embodiment 2

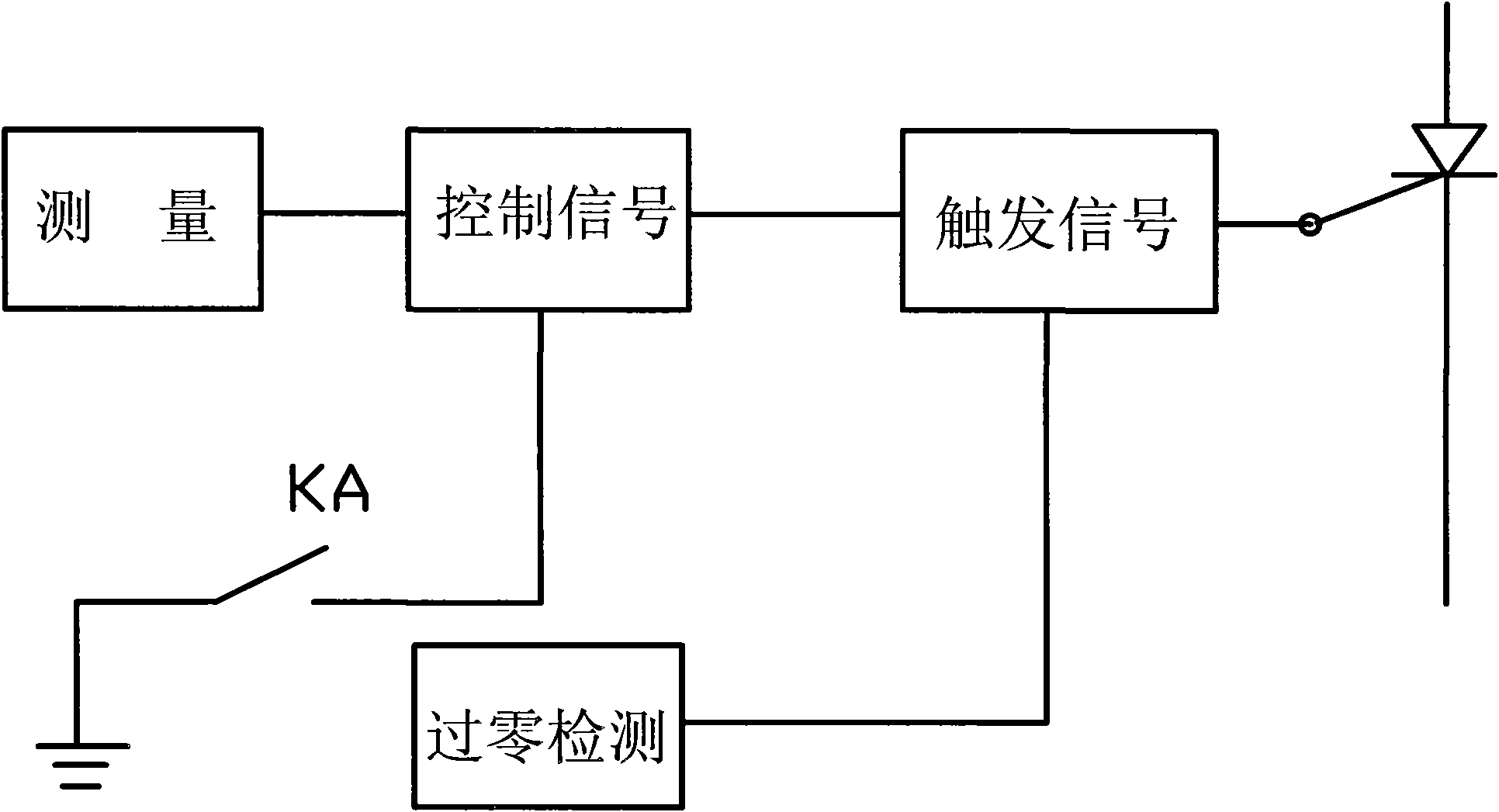

[0018] The method for protecting series reactor overheating and capacitor overcurrent protection described in Example 1, the normally open contact KSD of the device temperature switch used in the method is selected as a normally open contact, when the surface temperature of the reactor rises, it reaches Normally open contact KSD action temperature, normally open contact KSD action, the relay coil KA is energized, the normally open node is closed, which can be self-maintained, and at the same time another normally open node is closed to send this signal to the TSC controller to block the group Compensation control signal, this group of compensation exits the operation, and the controller sends out an alarm at the same time. After resetting, the capacitor will be put into operation automatically. When the maximum temperature of the Class B insulation reactor is 120°C, if only the maximum temperature of the reactor is considered, the control temperature range of the normally open con

Embodiment 3

[0020] In the method for protecting series reactors from overheating and also serving as capacitor overcurrent protection described in Embodiment 1, the model of the temperature control switch is KSD301, which can effectively set the temperature range of the temperature control switch.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap