Part polishing magnetic fixture capable of realizing spatial rotation

A technology of magnetic fixture and space rotation, which is applied to the parts of grinding machine tools, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of inconvenient adjustment of the angle of parts, danger of magnet power failure, and must be used with electricity, etc., to achieve Easy to clamp, easy to use, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

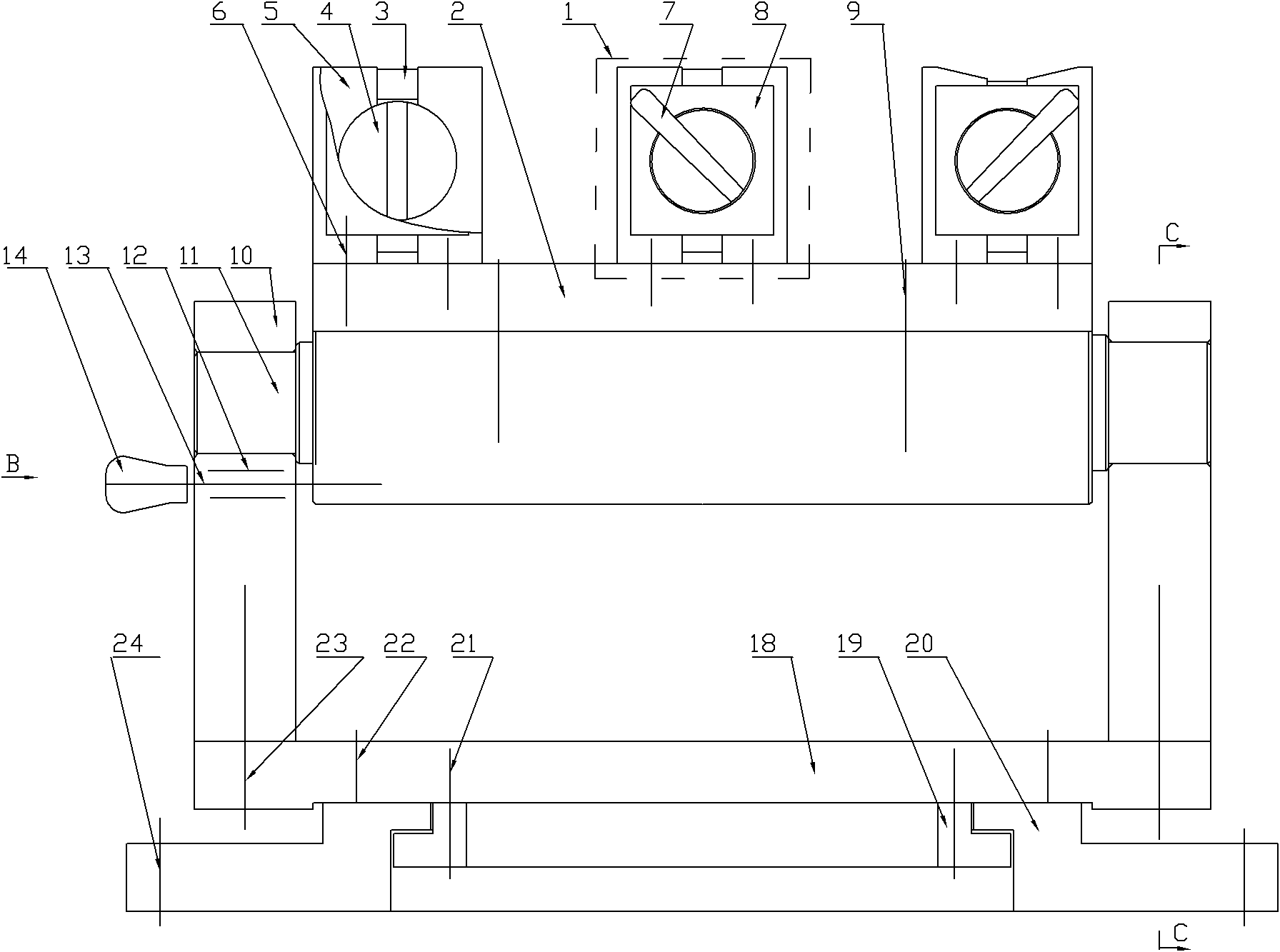

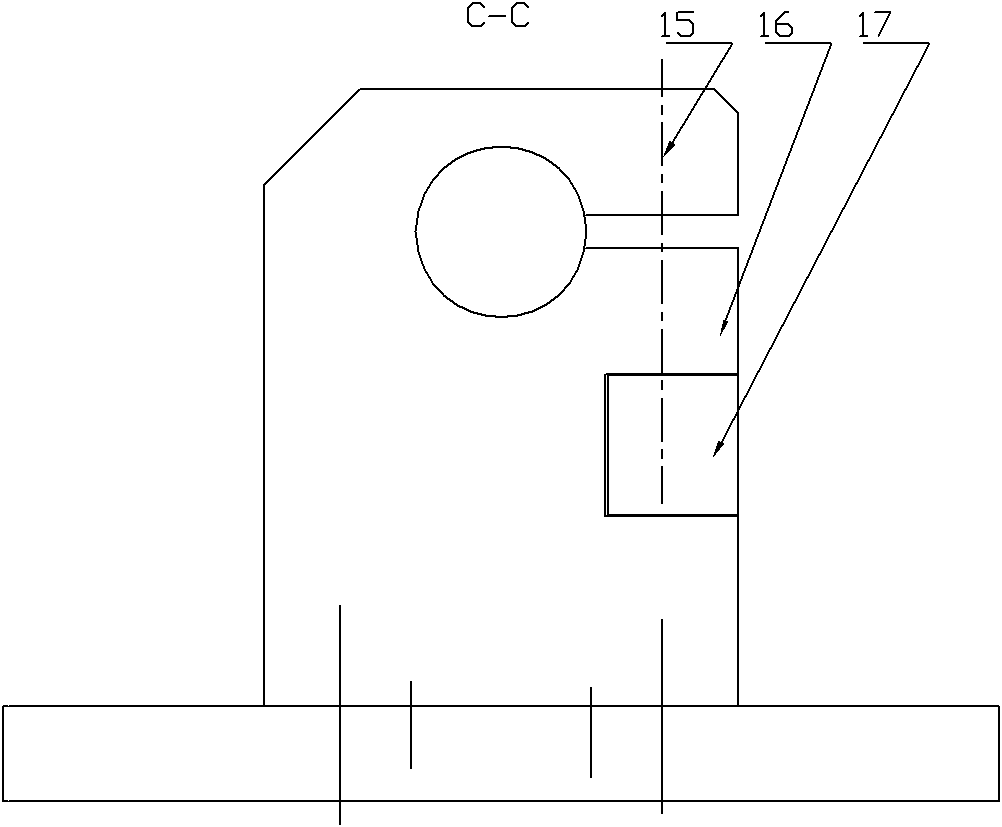

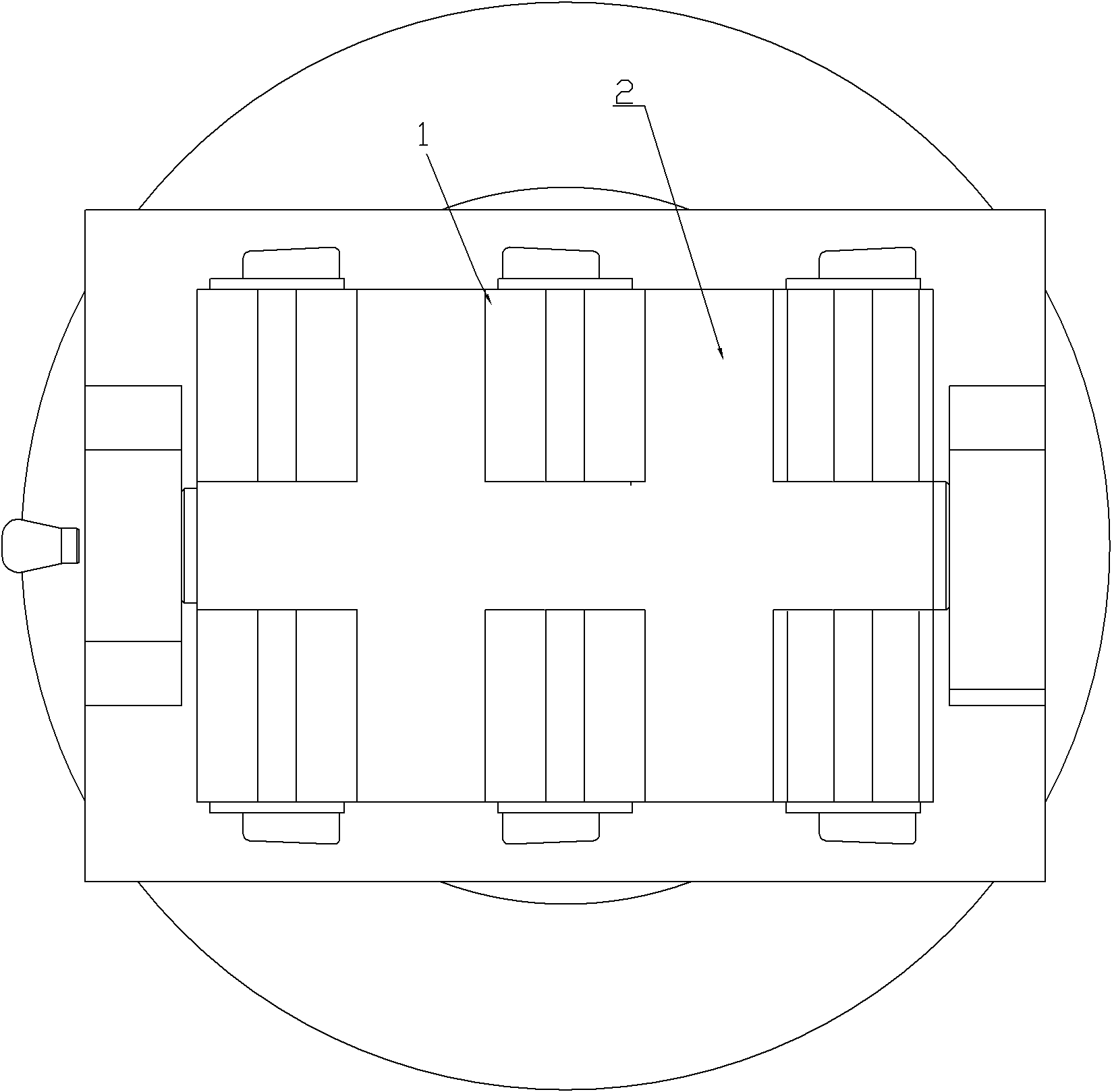

[0016] The present invention utilizes the magnetism of the switchable magnet 1 to fix the parts, the presence or absence of the suction of the switchable magnet 1 is controlled by rotating the magnet switch 7 by 90 degrees, and a plurality of identical switchable magnets 1 are connected to the platform plate 2 through the hexagon socket head cap screw a6, In the part magnetic block (5) of the switchable magnet 1, at least one magnetic block upper shape is V-shaped, and the shaft parts are fixed with the V-shaped magnetic block, and the platform plate 2 is connected with the hexagon socket head screw b9. The rotating shaft 11 is connected, and the rotating shaft 11 is clearance fit with the left vertical plate 10 and the right vertical plate 16 respectively so that the rotating shaft 11 can rotate freely. The upper part moves freely, the positioning cone pin 13 and the nut 14 are threadedly connected, and a spring 12 is sandwiched between the positioning cone pin 13 and the left ve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap