Full-automatic main material supply frame for radial tire building machine

A radial tire and molding machine technology, applied in the field of automatic feeding adjustment device, can solve the problems of large impact force of the feeding template and inaccurate fitting position, etc., achieve fast and stable operation, accurate fitting positioning, and shorten the working stroke and the effect of the round-trip time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

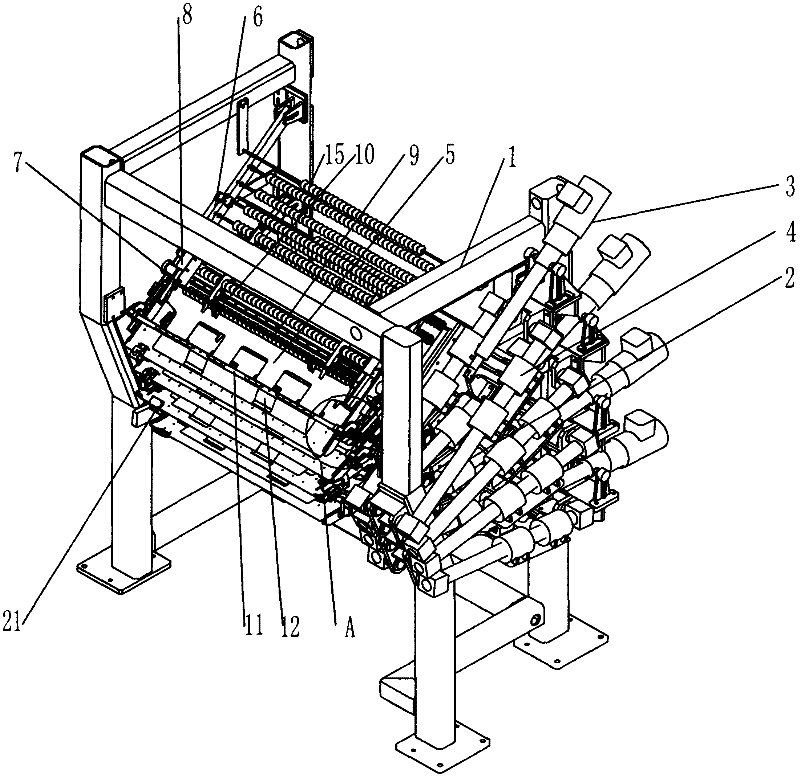

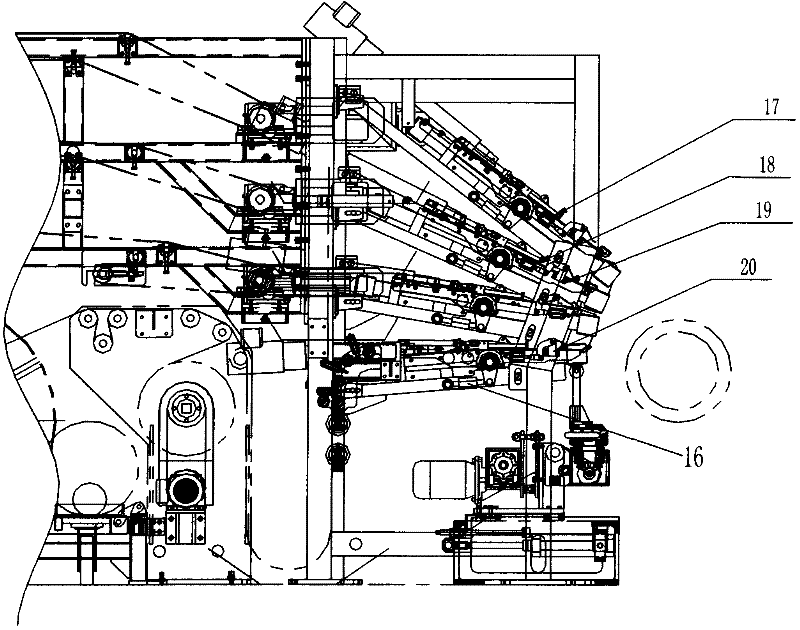

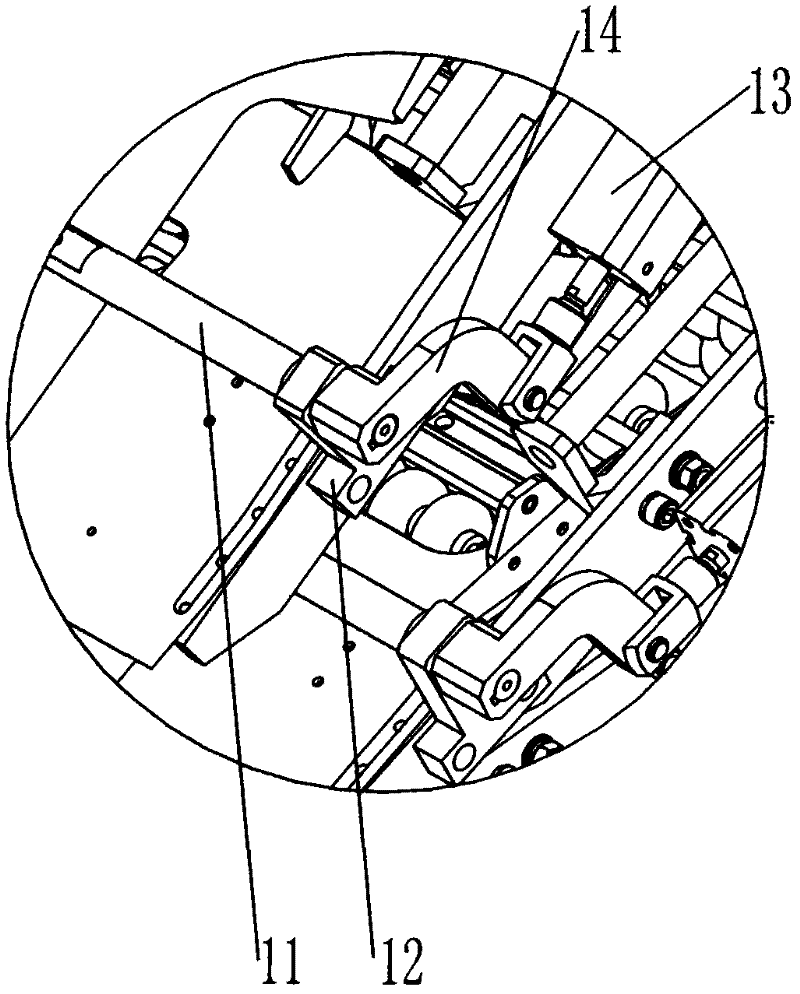

[0018] A full-automatic main supply rack for a radial tire building machine, comprising a supply rack 1 and a supply template arranged between the supply racks 1. A guide shaft 2 and an electric cylinder 3 are arranged on the outside of the supply rack 1 , The guide shaft 2 ensures the linear movement of the electric cylinder 3 to avoid vibration. The electric cylinder 3 drives the feeding template to move back and forth, which can be stopped at any position, the speed is controllable, and the impact on the feeding template and the forming drum is small. The sleeve is covered with a sliding sleeve 4, the feeding template is fixed to the sliding sleeve 4, and the piston of the electric cylinder 3 is connected with the sliding sleeve 4; the front end of the feeding template is provided with a secondary feeding device, and the secondary feeding device includes two The secondary feeding tray 5 and the secondary feeding cylinder 6, the secondary feeding cylinder 6 is fixedly mounted on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap