Preparation method of Nb-based amorphous alloy and stripe and hydrogen permeating metal film thereof

A technology of amorphous alloy and metal film, which is applied in the field of preparation of amorphous alloy and its strips and hydrogen permeable metal film, can solve the problems of high price of palladium, difficult large-scale industrial application, limited reserves, etc., and achieves improved hydrogen permeation. Effects on performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

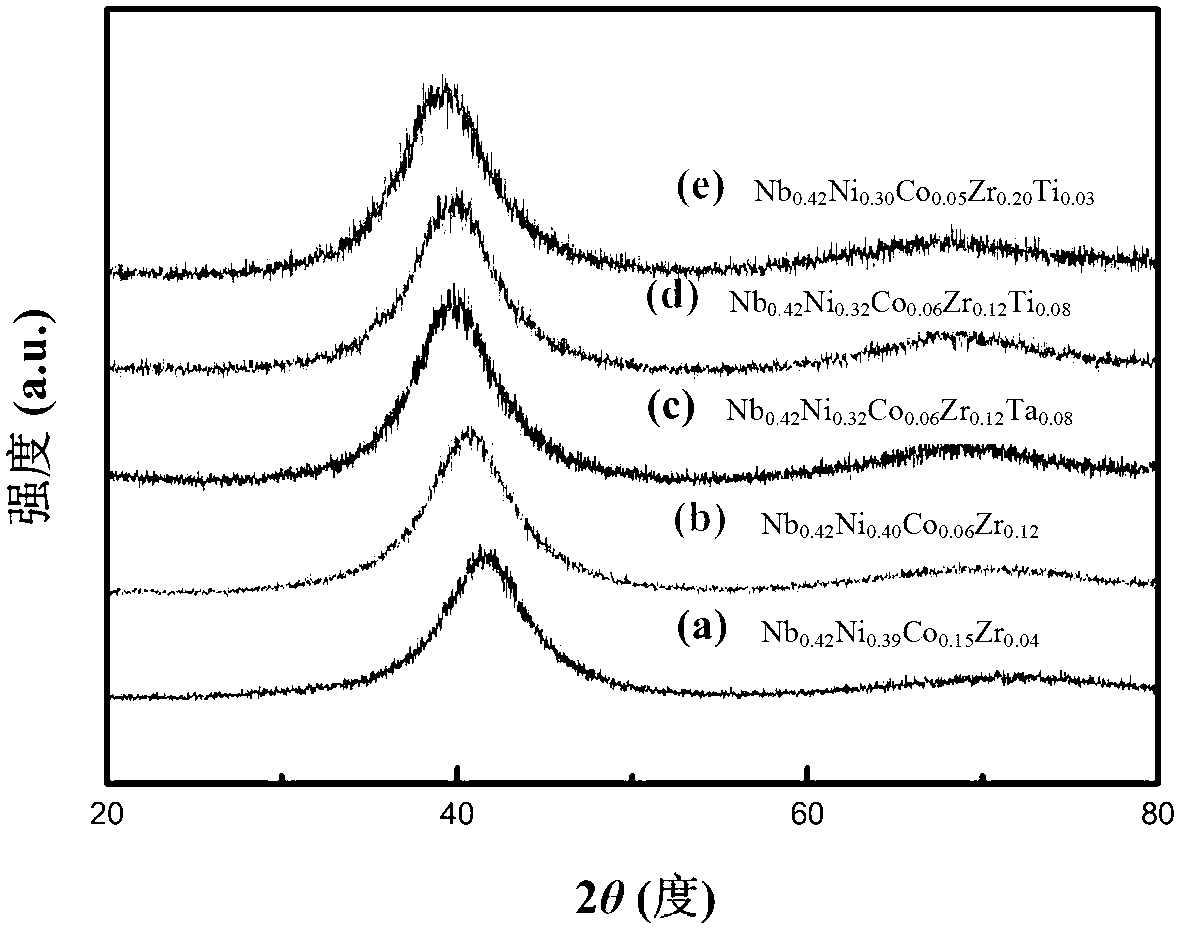

[0029] Example 1: Preparation of Nb 0.42 Ni 0.39 Co 0.15 Zr 0.04 Amorphous alloy

[0030] First, the raw materials with a purity of ≥99.9% are distributed according to the chemical composition ratio Nb 0.42 Ni a Co b Zr c M d Dosing is performed where a, b, c, d are atomic percent of each component, and a=0.39, b=0.15, c=0.04, d=0. Then it is repeatedly smelted in a vacuum arc furnace to obtain a master alloy with uniform composition. Better than 3×10 in vacuum -2 Under Pa vacuum conditions, the master alloy is placed in an induction furnace of a rapid solidification device to be melted to obtain a master alloy melt. The master alloy melt is sprayed onto the surface of the high-speed rotating copper roller, the surface linear velocity of the roller is about 20~40m / s, and the chemical composition of Nb is obtained by cooling. 0.42 Ni 0.39 Co 0.15 Zr 0.04 The Nb-based amorphous alloy strips were tested for their thermodynamic stability and hydrogen permeation proper

Embodiment 2

[0034] Example 2: Preparation of Nb 42 Ni 40 Co 6 Zr 12 Amorphous alloy

[0035] First, the raw materials with a purity of ≥99.9% are distributed according to the chemical composition ratio Nb 0.42 Ni a Co b Zr c M d Dosing is performed where a, b, c, d are atomic percent of each component, and a=0.40, b=0.06, c=0.12, d=0. Then it is repeatedly smelted in a vacuum arc furnace to obtain a master alloy with uniform composition. Better than 3×10 in vacuum -2 Under Pa vacuum conditions, the master alloy is placed in an induction furnace of a rapid solidification device to be melted to obtain a master alloy melt. The master alloy melt is sprayed onto the surface of the high-speed rotating copper roller, the surface linear velocity of the roller is about 20~40m / s, and the chemical composition of Nb is obtained by cooling. 0.42 Ni 0.40 Co 0.06 Zr 0.12 The Nb-based amorphous alloy strips were tested for their thermodynamic stability and hydrogen permeation properties. Th

Embodiment 3

[0039] Example 3: Preparation of Nb 0.42 Ni 0.32 Co 0.06 Zr 0.12 Ta 0.08 Amorphous alloy

[0040] First, the raw materials with a purity of ≥99.9% are distributed according to the chemical composition ratio Nb 0.42 Ni a Co b Zr c M d Dosing is performed where M is Ta, a, b, c, d are atomic percent of each component, and a=0.32, b=0.06, c=0.12, d=0.08. Then it is repeatedly smelted in a vacuum arc furnace to obtain a master alloy with uniform composition. Better than 3×10 in vacuum -2 Under Pa vacuum conditions, the master alloy is placed in an induction furnace of a rapid solidification device to be melted to obtain a master alloy melt. The master alloy melt is sprayed onto the surface of the high-speed rotating copper roller, the surface linear velocity of the roller is about 20~40m / s, and the chemical composition of Nb is obtained by cooling. 0.42 Ni 0.32 Co 0.06 Zr 0.12 Ta 0.08 The Nb-based amorphous alloy strips were tested for their thermodynamic stability

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset crystallization temperature | aaaaa | aaaaa |

| Onset crystallization temperature | aaaaa | aaaaa |

| Onset crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap