Seam-penetrating drilling hydrofracturing gas extracting method

A hydraulic fracturing and gas extraction technology, which is applied in gas discharge, earthwork drilling, mining equipment, etc., can solve the problems of large gas engineering volume, low drilling utilization rate, low extraction efficiency, etc., so as to overcome the low utilization rate. , the effect of improving gas extraction efficiency and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

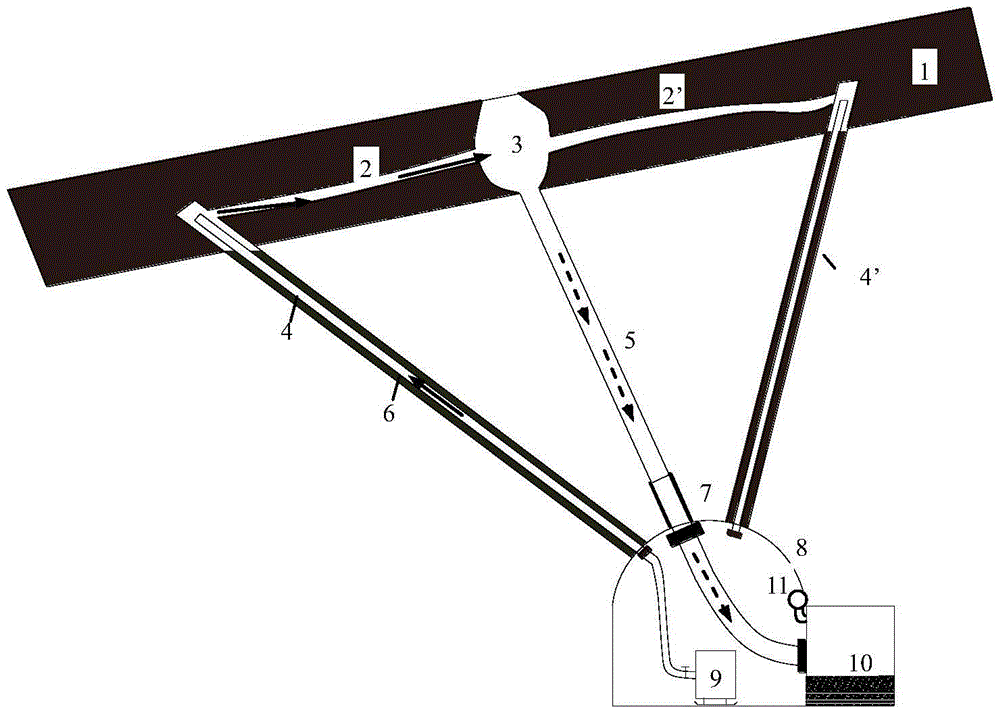

[0018] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

[0019] Such as figure 1 As shown, the specific steps of the method for extracting coal seam gas by hydraulic fracturing of the present invention are as follows:

[0020] a. Construct a target borehole 5 with a diameter of 100mm that penetrates the coal seam 1 in 20-30m away from the bottom of the coal seam 1 and in a stable rock roadway 8, and ream the coal seam section of the target borehole 5 according to conventional technology to form Target hole 3;

[0021] b. Ream the 5 orifice section of the target borehole with a reaming length of 1.5m and a reaming diameter of 130mm. Place a casing 7 with a diameter of 100mm in the reaming section, and fix the casing 7 with quick-setting cement. Then connect the sleeve 7 and the separation chamber 10 with a high-pressure hose;

[0022] c. Construct a hydraulic rupture borehole 4 on both sides of the target borehole 5 t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap