Screw compressor directly driven by turbine and driving method

A technology for screw compressors and steam turbines, applied in machines/engines, pump combinations for elastic fluid rotary piston type/swing piston type, mechanical equipment, etc., can solve problems such as high cost and waste of energy, and achieve energy saving, The effect of reducing cost and saving power system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

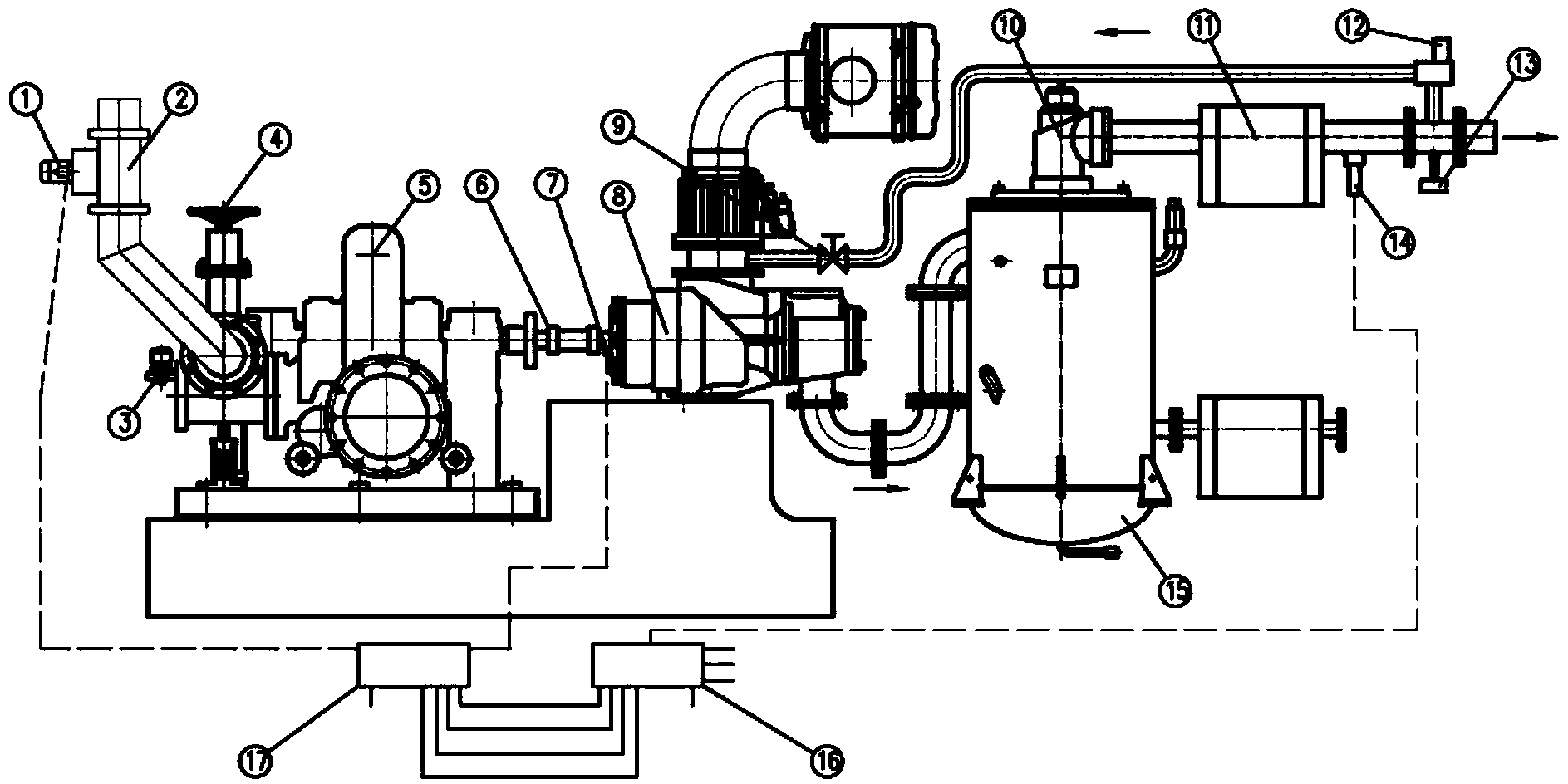

[0035] The structure diagram of the screw compressor based on the direct drive of the steam turbine of this embodiment is as follows: figure 1 Shown. The screw compressor based on the direct drive of the steam turbine includes a drive steam turbine 5 and a screw compressor 8. The mechanical output end of the drive steam turbine 5 and the mechanical input end of the screw compressor 8 are connected by a coupling 6; A rotational speed sensor 7 is provided at the connection between the mechanical output end and the mechanical input end of the screw compressor 8;

[0036] The steam inlet of the driving steam turbine 5 is provided with a steam inlet valve 2, and the steam inlet valve 2 is provided with a servo motor 1 for controlling the opening size of the valve. The steam inlet is also provided with a steam inlet opening handwheel 4 and a steam turbine emergency stop. Device 3;

[0037] The screw compressor 8 is connected to an oil separator 15; the top of the oil separator 15 is connec

specific Embodiment 2

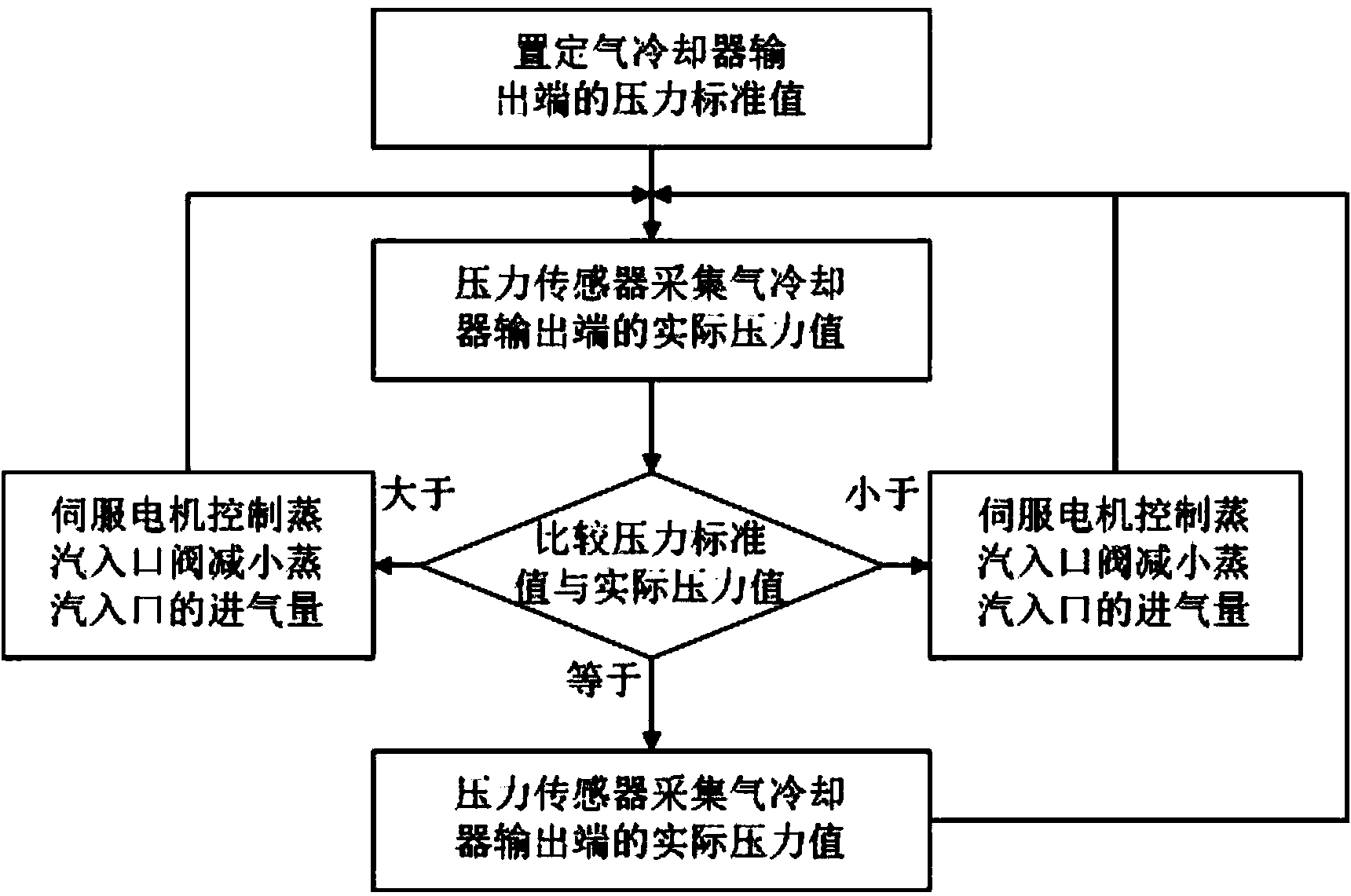

[0052] The method for the steam turbine to directly drive the screw compressor in this embodiment is implemented by adopting the following steps:

[0053] Step a: Calibrate the relationship between the pressure standard value at the output end of the air cooler 11 and the speed standard value of the speed sensor 7;

[0054] Step b. The rotation speed sensor 7 collects the actual rotation speed value of the mechanical output end of the driving steam turbine 5 and transmits it to the driving steam turbine PLC17;

[0055] Step c, drive the steam turbine PLC17 to compare the speed standard value of step a with the actual speed value of step b;

[0056] Step d. Drive the steam turbine PLC17 to control the servo motor 1, and:

[0057] If the actual speed value is greater than the speed standard value, the steam turbine PLC17 is driven to control the servo motor 1, so that the steam inlet valve 2 reduces the air intake of the steam inlet;

[0058] The actual speed value is equal to the standard sp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap