Multifunctional three-stand column hydraulic automatic forming machine special for stone-free non-fired and non-steamed building blocks

An automatic forming, multi-functional technology, used in ceramic forming machines, forming indenters, auxiliary forming equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

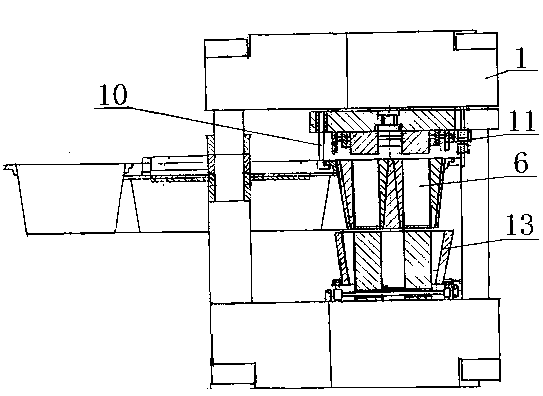

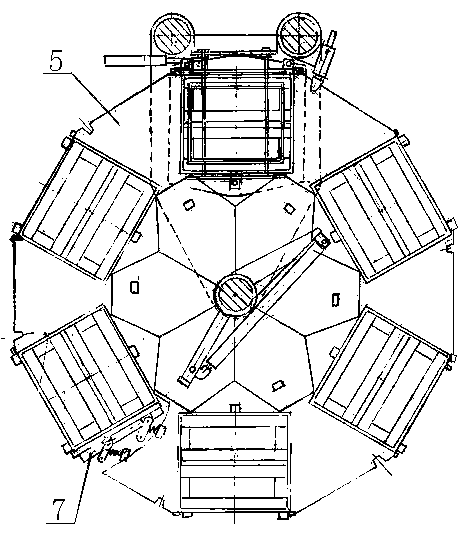

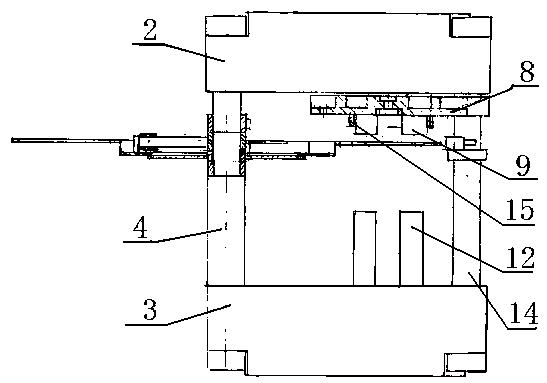

[0033]Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises a three-column hydraulic press 1, a beam 2 and a base 3 are arranged on the three-column hydraulic press 1, a central column 4 is arranged between the beam 2 and the base 3, and six mold feeding trays 5 are installed on the central column 4, and the mold Six blanking molds 6 are placed in the hexagonal holes between the feeding trays 5, mold holders 7 are respectively installed under both sides of the hexagonal holes, and movable mounting plates 8 are installed on the lower part of the crossbeam 2. Two upper pressing heads 9 are installed on the lower part of the plate 8, three groups of die lifters 10 are installed on the movable mounting plate 8, a mold release device 11 is also installed on the movable mounting plate 8, two lower pressing heads 12 are fixed on the base 3, the base 3 is also equipped with mold floating reinforcement 13. An outer column 14 is arranged

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap