Fuel oil conveying pipeline with muffling device

A sound-absorbing device and conveying pipeline technology, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve problems such as loud noise, interruption of oil supply system, blockage of fuel injectors, etc., and achieve the effect of reducing noise and slowing down the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

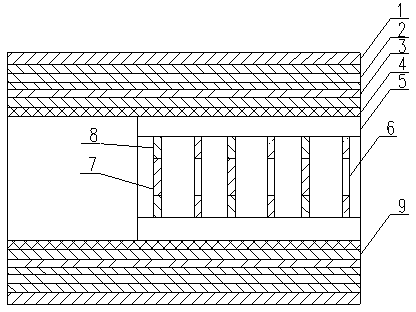

[0024] Such as figure 1 As shown, the present application provides a fuel delivery pipeline with a noise reduction device, including a protective layer 1, a support layer 2, an isolation layer 3 and a low precipitation layer 4 arranged in sequence, wherein the liquid outlet end of the pipeline is arranged at A sound-absorbing device, the sound-absorbing device includes a casing 5 sleeved in the low precipitation layer 4, and alternately arranged first labyrinth plates 6 and second labyrinth plates 7 in the shell 5, the first labyrinth plates 6 are annular structures, The second labyrinth plate 7 is a disc structure, the outer edge of the first labyrinth plate 6 is fixed on the shell 5, the second labyrinth plate 7 is arranged on the middle part of the shell 5 by the connector 8, and the second labyrint

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap