Exterior wall glass-fiber reinforced concrete coping type installation method

A technology for reinforcing concrete and glass fiber, which is applied in the direction of architecture and building structure, etc., to achieve the effect of harmonious and beautiful appearance, speed up installation and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

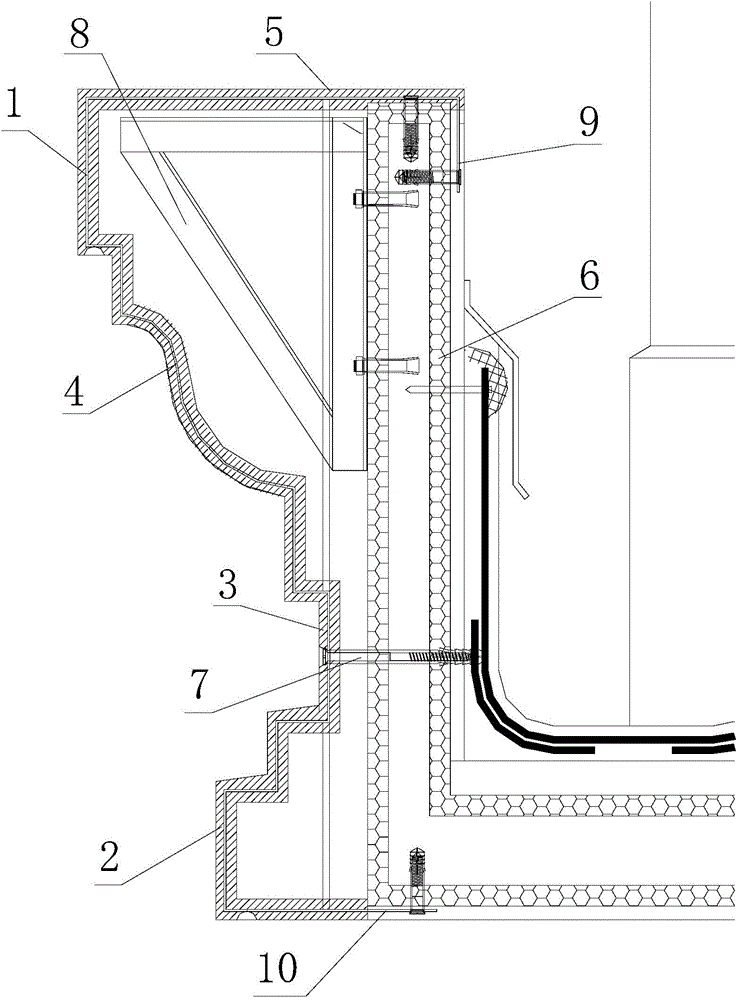

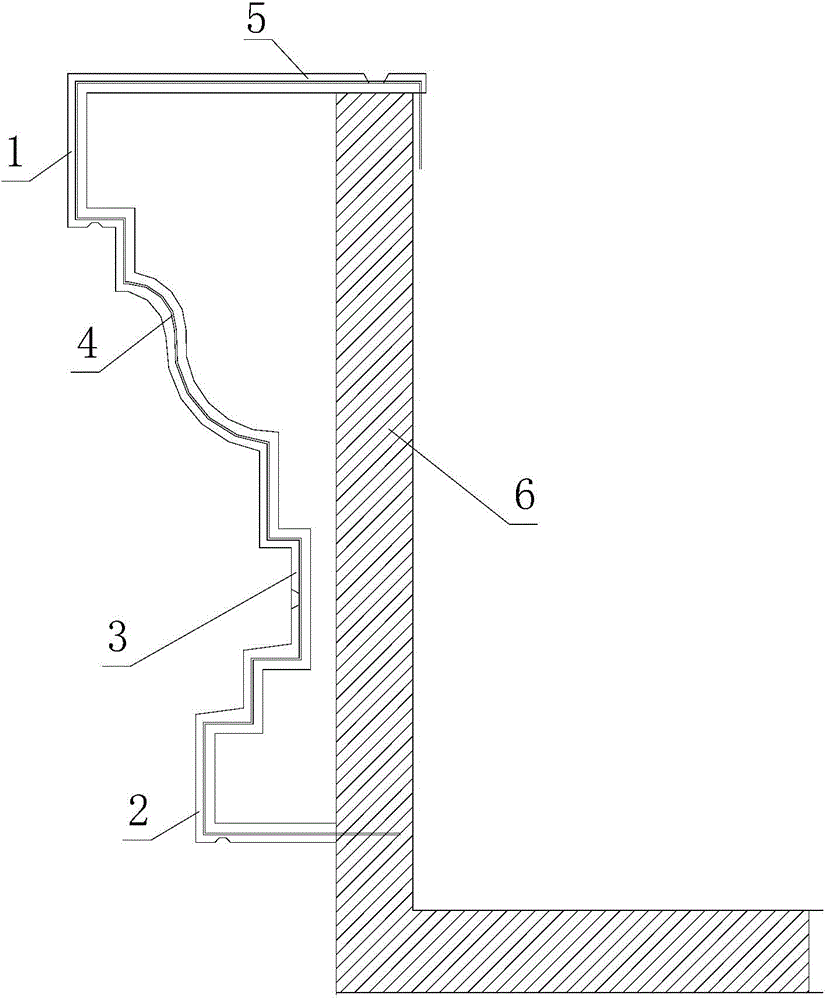

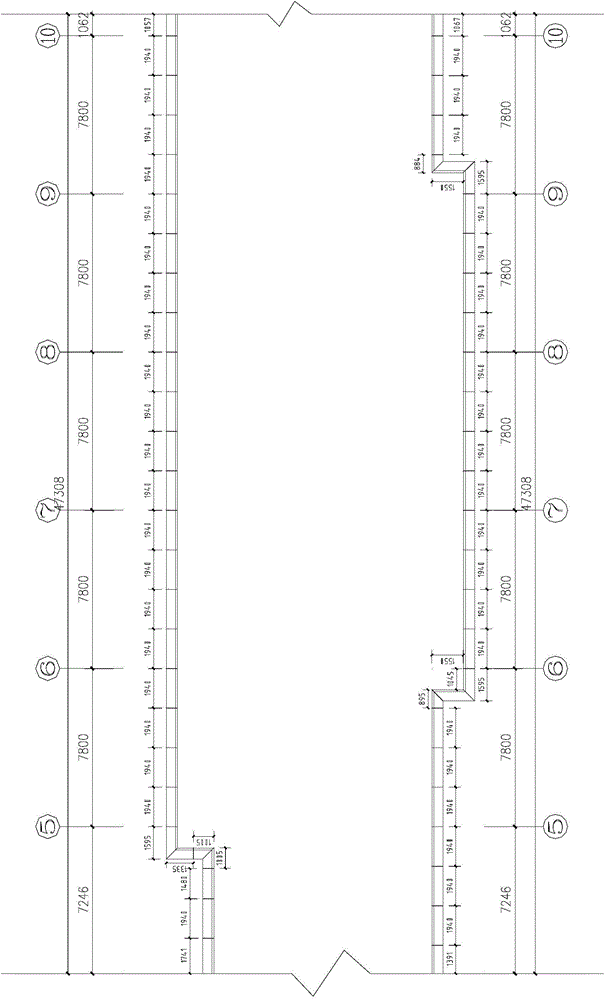

[0054] see figure 1 and image 3 ,

[0055] The action principle of the present invention is:

[0056] 1. Carry out secondary deepening design on drawings

[0057]1). According to the requirements of the construction drawing, the second deepening design is carried out, and the unified design of the glass fiber reinforced concrete lines is carried out according to the overall facade effect of the design and the arrangement of the line separation joints of the facade. In the design, the layout of the lines is fully considered to make the plates uniform in size, and the overall effect is obviously the first element.

[0058] 2). In the second design, the installation method of the line was also adjusted accordingly, and the traditional side in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap