Floor heating structural body and laying method thereof

A structure and floor heating technology, which is applied in heating methods, building structures, lighting and heating equipment, etc., can solve the problems of chaotic wiring of carbon fiber heating cables, reduce the height of buildings, and thick laying, so as to save materials and reduce construction period , the effect of thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

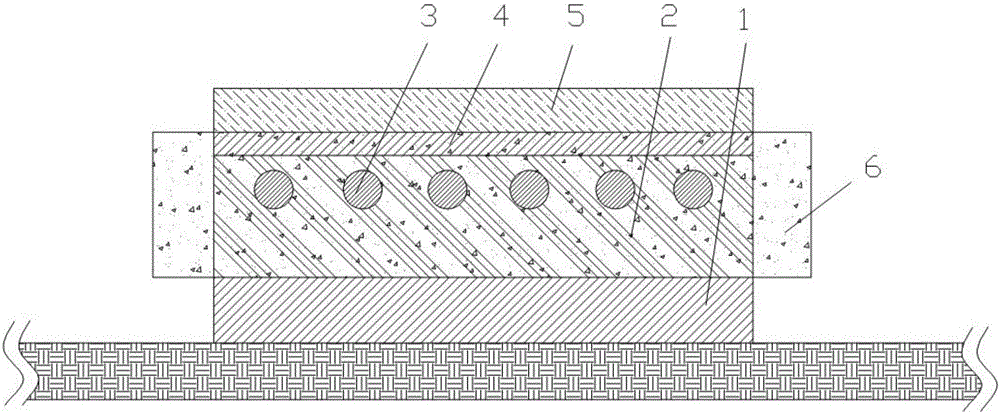

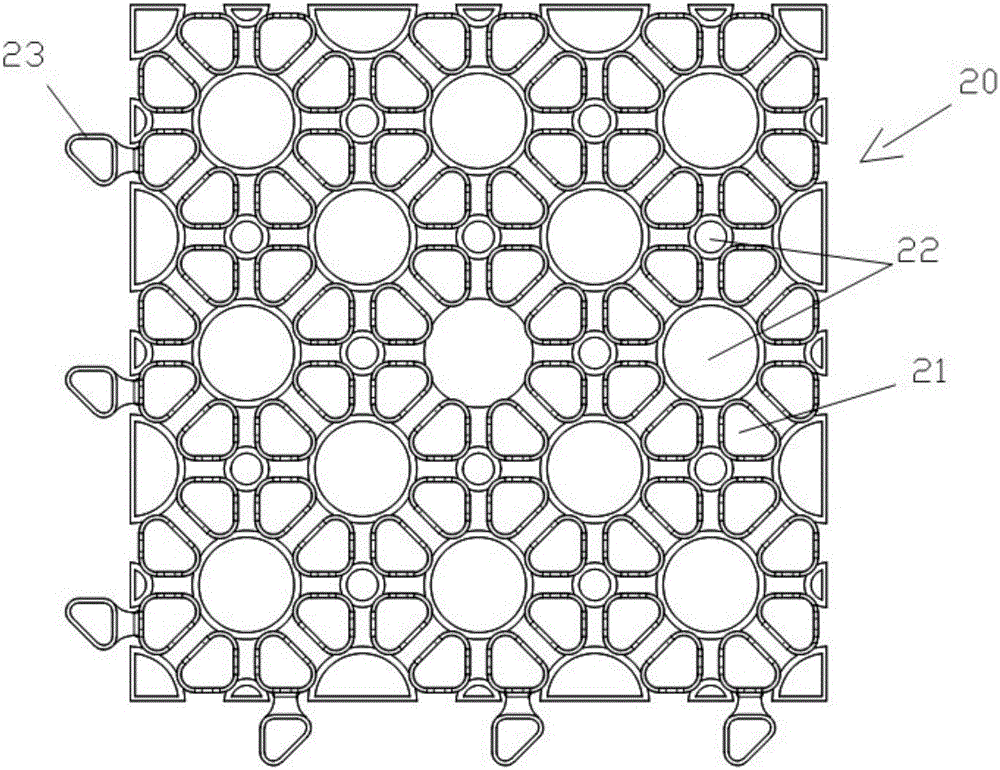

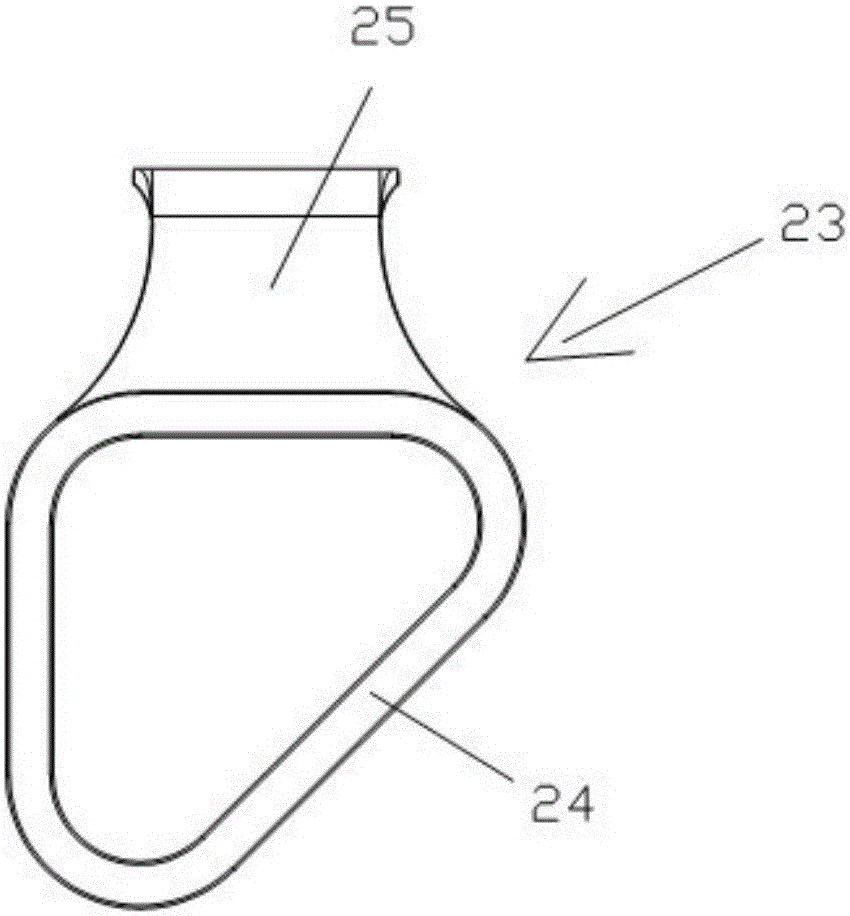

[0021] refer to figure 1 , which shows the floor heating structure of the present invention, which is laid on the ground or the base layer of the floor as a whole, and uses the heat storage and heat radiation of the ground itself to heat the entire ground, thereby increasing the temperature in a specific space. The floor heating structure includes a hard insulation layer 1, a laying layer 2, a cable net 3, a reinforced barbed wire 4, a ground decoration layer 5, and a cement layer 6 filled between the hard insulation layer 1 and the ground decoration layer 5.

[0022] Specifically, the hard insulation layer 1 is laid on the ground or the base layer of the floor, and is the supporting part of the entire floor heating structure, so its compressive capacity must be extremely high, otherwise it will cause

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap