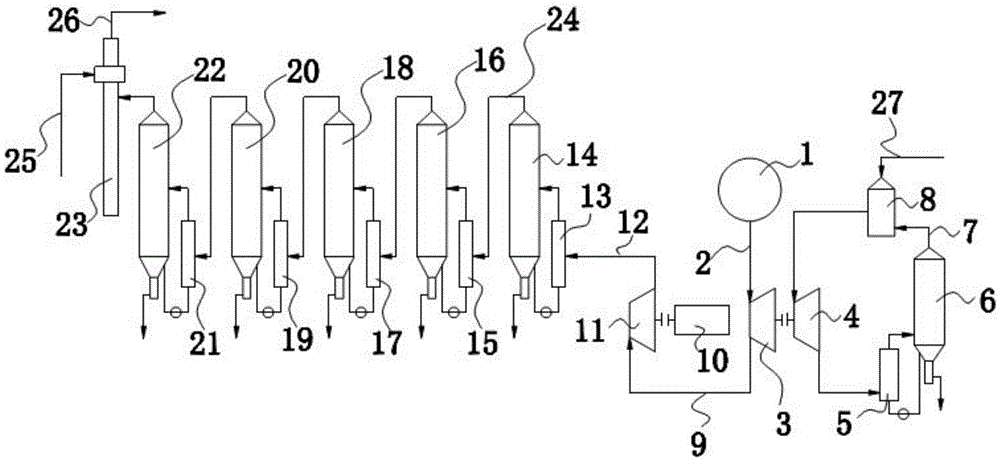

MVR and ME combined heat and power generation salt production system and technology thereof

A technology of combined heat and power, heating chamber, applied in the direction of sustainable manufacturing/processing, chemical industry, alkali metal chloride, etc., can solve the problems of insufficient energy utilization, low-grade heating, etc., to achieve multi-level ladder utilization, Improve the heating grade and enhance the effect of internal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0032] In the description of the present invention, unless otherwise specified, "plurality" means two or more.

[0033] In the description of the present invention, it should be noted that, unless otherwise clearly defined and limited, the term "connection" should be understood in a broad sense, for example, it can be a fixed connection, a detachable connection, or an integral connection; It is a mechanical connection or an electrical connection; it can be directly connected, or indirectly connected through an intermediate medium, and it can be the internal communication bet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap