Novel hole puncher

A puncher and a new type of technology, applied in the field of machinery, can solve the problems of non-adjustable distance, no pressing device, inconvenience, etc., and achieve the effects of simple operation, convenient carrying and guaranteeing of punching accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further described in detail below in conjunction with the drawings, but it is not a limitation of the present invention.

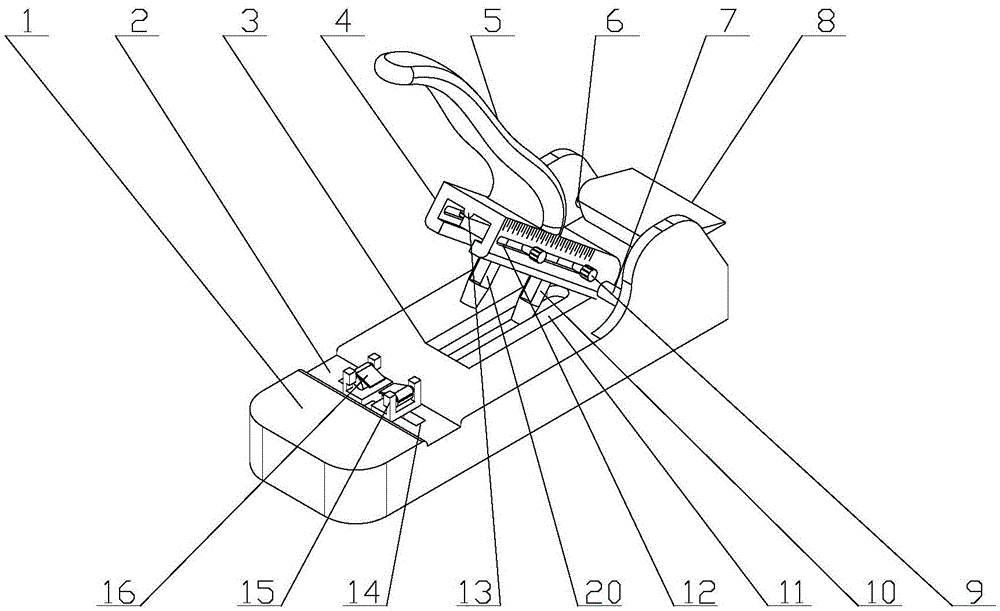

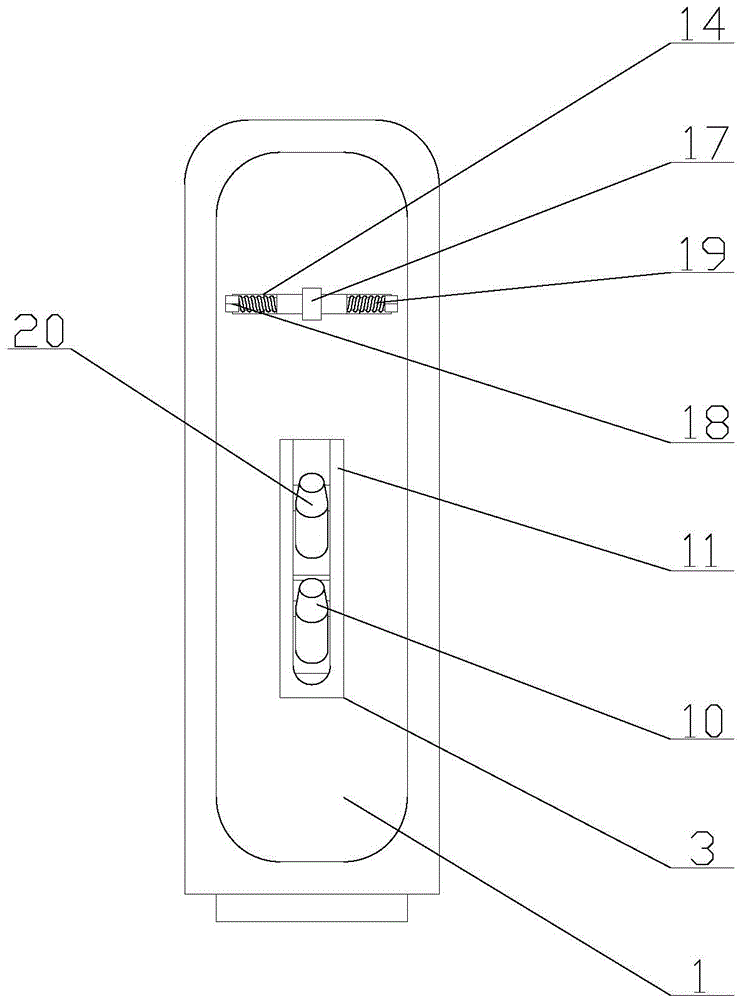

[0014] See attached figure 1 , figure 2 , image 3 , Figure 4 , A new type of punch, characterized in that it includes a base (1), a slider (4), a handle (5), a fixed shaft B (6), a fixed shaft A (7), and a pressing plate A (8) , Locking rod (9), punching nails (10, 20), template (11), the handle (5) is welded to the slider (4), and the slider (4) is mounted on the fixed Shaft A (7), the fixed shaft A (7) is equipped with a torsion spring in the middle position, under the action of the torsion spring, the handle (5) can automatically spring up after the end of the hole, the pressure plate A ( 8) Installed on the fixed shaft B (6) for compression, the fixed shaft A (7) and the fixed shaft B (6) are installed on the two side baffles at the rear of the base (1) respectively Play the role of fixing the sliding block (4) and t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap