Nano silver @ polyvinylidene fluoride antibacterial separation membrane and preparation method

A technology of polyvinylidene fluoride and nano-silver, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., and can solve problems such as shortened service life, single membrane material cannot meet practical application requirements, and membrane flux decline , to achieve the effects of no harmful substances to health, enhanced anti-pollution ability, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

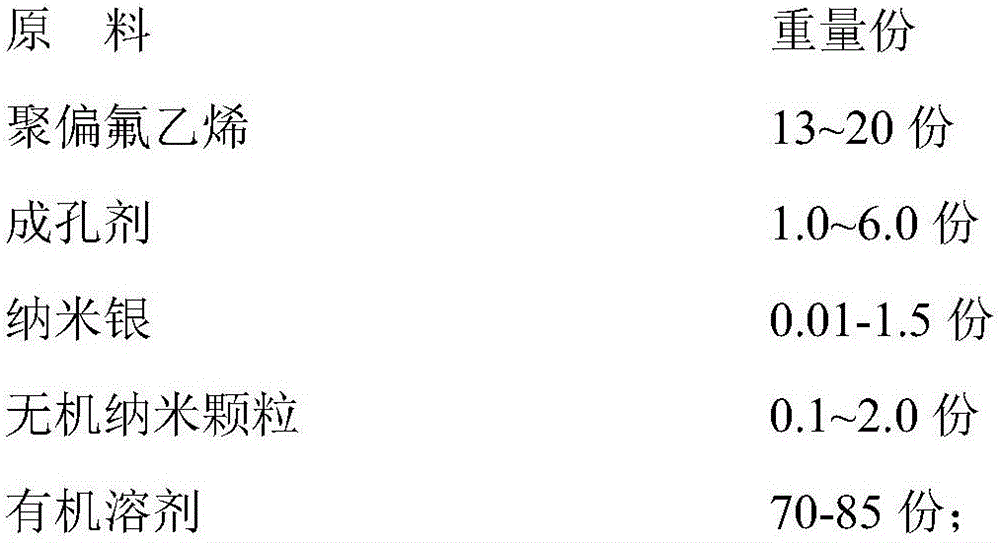

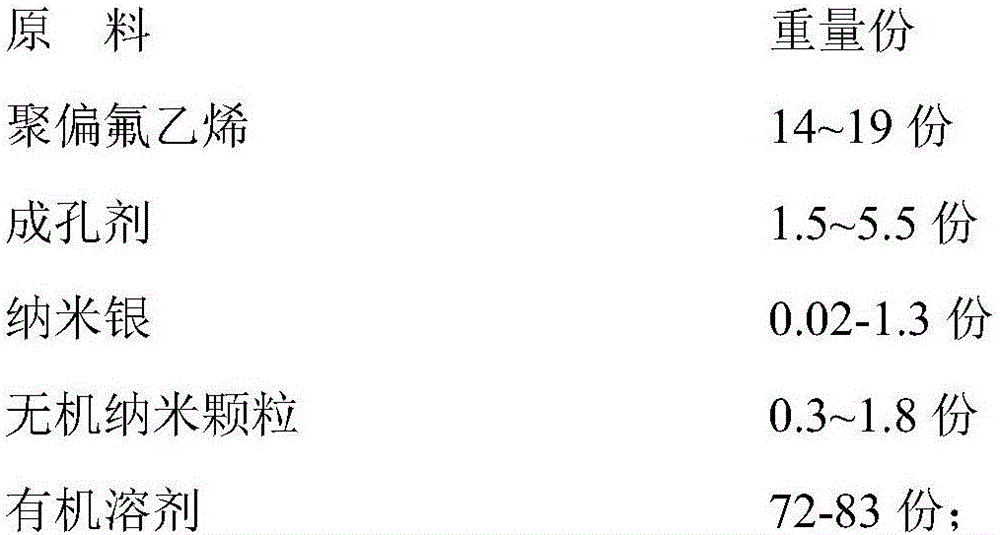

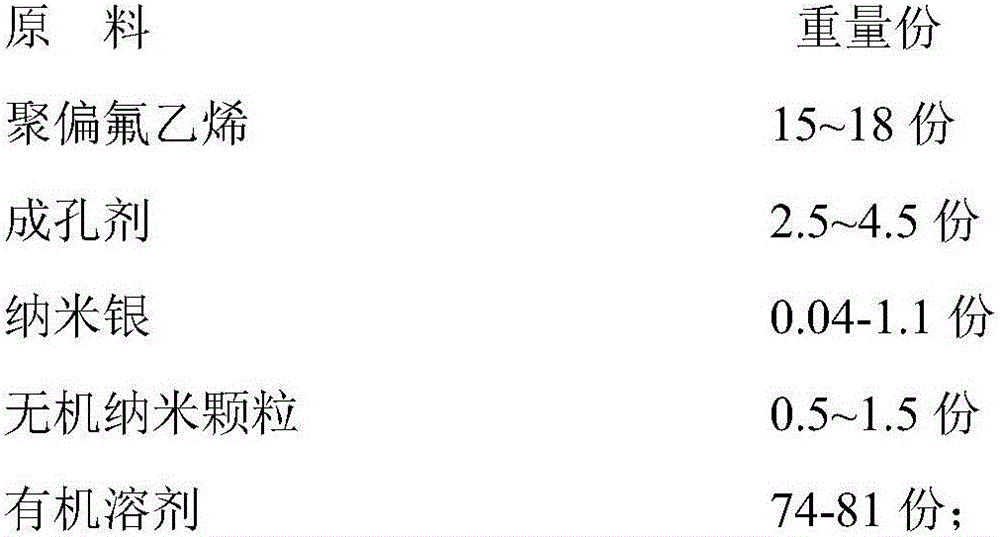

[0027] A kind of nano-silver polyvinylidene fluoride antibacterial separation membrane, it is made of the raw material of following weight part:

[0028]

[0029] A preparation method of nano-silver polyvinylidene fluoride antibacterial separation membrane, the steps are:

[0030] A. Add the weighed pore forming agent and nanomaterials into the weighed organic solvent and ultrasonically disperse for 20 or 30 or 40 or 50 or 60 minutes;

[0031] B. Add and weigh other materials into the organic solvent, stir mechanically for 1 or 1.5 or 2 hours, and let stand for 24 or 28 or 32 or 38 or 44 or 48 hours for defoaming to obtain the casting solution;

[0032] C. Under the condition of 20 or 24 or 26 or 28 or 30 ℃, scrape the casting solution on the glass plate to form a film, slowly put it into the coagulation solution and soak it until the film falls off, and at room temperature (20 or 22 or 24 or 25 After rinsing the membrane with distilled water at ℃), put it into deionized wate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap