Cyanide-free Au-Sn alloy plating solution and preparing method and application thereof

A technology of au-sn and alloy, which is applied in the field of cyanide-free Au-Sn alloy plating solution and its preparation, can solve the problems such as the turbidity of the plating solution and the poor stability of the plating solution, and achieve the advantages of simple preparation method, easy operation and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A cyanide-free Au-Sn alloy plating solution prepared from the following raw material components: (referred to as the plating solution formula in the following examples)

[0043]

[0044] Au-Sn alloy plating solution plating solution preparation method:

[0045] ①The chloroauric acid solution (which contains 0.001 mol of chloroauric acid), adjust its pH to 7 with 10% sodium hydroxide solution; then add it to the 5,5-two with 30% NaOH solution to adjust the pH to 10 In the methyl hydantoin solution (which contains 0.012 mol of 5,5-dimethyl hydantoin), heat the reaction in a water bath at 45°C for 24 hours. The solution turns from pale yellow to colorless, which is Au(III) -5,5-Dimethylhydantoin complex;

[0046] ②Add 30mL deionized water into the beaker, add 0.012mol sodium sulfite, 0.0015mol disodium ethylenediaminetetraacetic acid and the Au(III)-5,5-dimethylhydantoin complex obtained in step ① in sequence , React for 20 minutes to obtain solution I;

[0047] ③Add 30mL of ionize

Embodiment 2

[0052]

[0053] The preparation method is the same as that of Example 1, except that the raw material components and component concentrations are different from those of Example 1. The electroplating temperature is 45℃, adopts the commutation pulse electroplating method, and the forward peak current density is 15mA / cm 2 , The forward and reverse current density ratio is 5:1, the pulse period is 10ms, and the pulse forward and reverse conduction and turn-off time is 2ms:5ms:1ms:2ms. The electroplating time is 20 minutes, and a silver-white bright eutectic alloy with Au-30at.% Sn plating is obtained.

[0054] Such as figure 2 Shown is the SEM image of the Au-30at.% Sn eutectic alloy obtained in this example.

Embodiment 3

[0056]

[0057] Except that the raw material components and component concentrations are different from those in Example 1, the preparation method is the same as that in Example 1. The electroplating temperature is 55°C, the commutation pulse electroplating method is adopted, and the forward peak current density is 30mA / cm 2 , The forward and reverse current density ratio is 4:1, the pulse period is 10ms, and the pulse forward and reverse conduction and turn-off time is 2ms:4ms:1ms:3ms. The electroplating time is 1 hour, and the obtained coating is Au-46at.% Sn alloy coating.

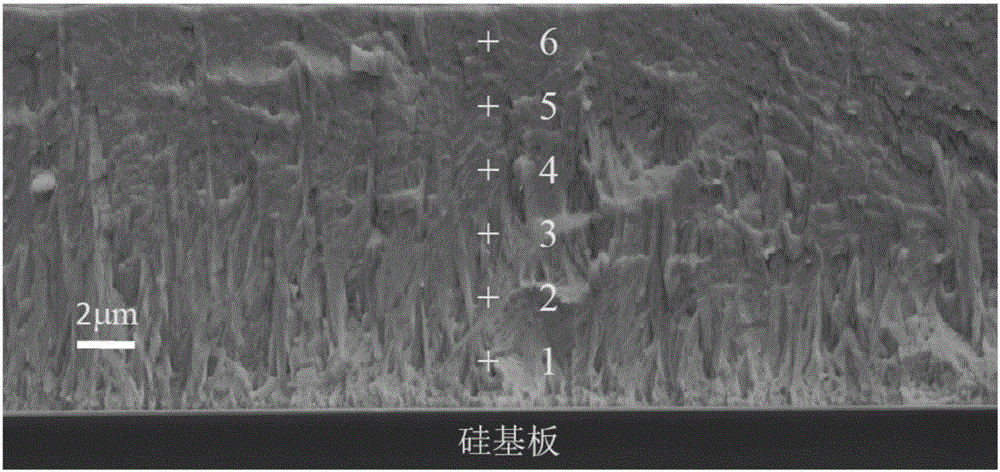

[0058] Such as image 3 Shown is the composition diagram of each point of the cross-section of the plating layer after electroplating with the plating solution described in this embodiment for 1 hour.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap