Positive plate capable of improving lithium nickel manganese oxide battery capacity and lithium nickel manganese oxide battery applying positive electrode plate

A technology of lithium nickel manganese oxide and battery capacity, applied in the field of lithium nickel manganese oxide battery, can solve the problems of multi-active lithium ions, blockage of lithium ion channels, collapse of crystal structure, etc., and achieve the effect of improving battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a lithium nickel manganese oxide battery, including a battery main body, a negative electrode arranged on the battery main body and made of graphite, a positive electrode sheet arranged on the battery main body and corresponding to the negative electrode, and a battery filled in the battery main body. electrolyte in the

[0025] In terms of mass percentage, the positive electrode sheet contains the following components: 3wt% compound, 5wt% conductive agent, 3wt% binder, and a positive electrode active material composed of lithium nickel manganese oxide that occupies the remaining proportion;

[0026] The compound is lithium iron phosphate;

[0027] Correspondingly, lithium titanate, lithium vanadate or lithium peroxide are all the same as lithium iron phosphate, which can realize the extraction of lithium ions at a lower voltage; they can be substituted for each other when needed;

[0028] The conductive agent is carbon black;

[0029] The binder

Embodiment 2

[0033] Example 2 is basically the same as Example 1, the only difference is that the content of the compound is 5wt%.

Embodiment 3

[0035] Embodiment 3 is basically the same as Embodiment 2, the only difference is: the compound content is 8wt%.

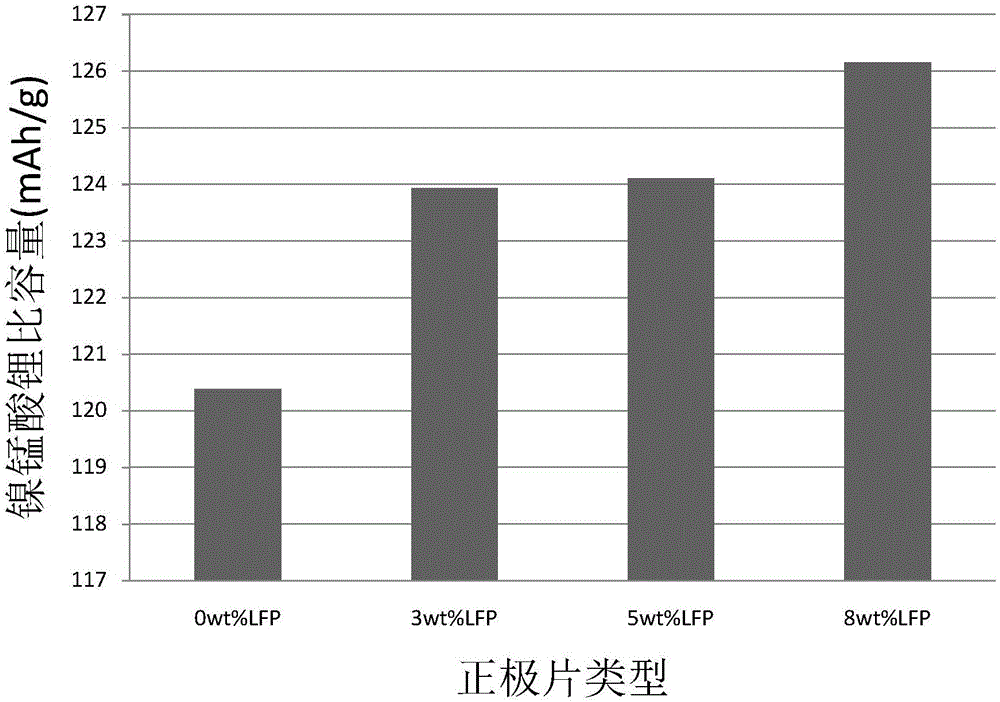

[0036] refer to figure 1 , and in conjunction with embodiment 1, embodiment 2, and embodiment 3 and simultaneously add the lithium nickel manganese oxide battery used at the present stage to run at a voltage interval of 3.5 with a charge and discharge rate of C / 3; and obtain the battery used at the present stage, Embodiment 1, embodiment 2, and the specific capacity of its corresponding lithium nickel manganese oxide of embodiment 3;

[0037] At this time, lithium iron phosphate is completely oxidized to iron phosphate and does not participate in the electrochemical reaction, so the battery capacity comes entirely from lithium nickel manganese oxide. At the same time, as the amount of lithium iron phosphate in the positive electrode increases, the specific capacity of lithium nickel manganese oxide It will increase accordingly; lithium nickel manganese oxide is th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap