Nine-block box modular design method for robot plate deploying and retracting machine

A technology of modular design and robotics, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reducing design efficiency, increasing costs, and confusing equipment layout, and achieve the effect of improving design efficiency and reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

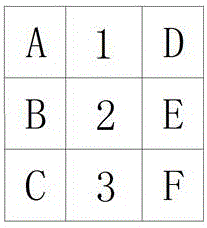

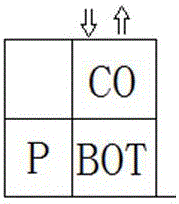

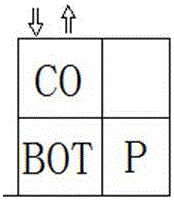

[0024] A nine-square modular design method for a robot retractable trigger, characterized in that the method includes the following steps: A, designing each component in the robot retractable trigger into a standardized module, and the components of the robot retractable trigger include A robot and adsorption system, a conveying section assembly, and at least one PCB carrier placement platform, each of which is designed as a first-type module or a second-type module, the first-type modules have the same size, and the second-type modules have the same Dimensions, the robot, the adsorption system, and the conveying section components are the second type modules, and the PCB carrier placement platform is the first type module or the second type module; B. Arrange the components of the robot retractable trigger into 3 rows The nine-square grid layout of colu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap