Quartz boat testing tool

A checking tool and quartz technology, applied in the field of quartz boat checking tool, can solve the problems of quartz boat accuracy or benchmark discrepancy, differences among multiple automation equipment, etc., and achieve the effect of improving the efficiency of boat testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

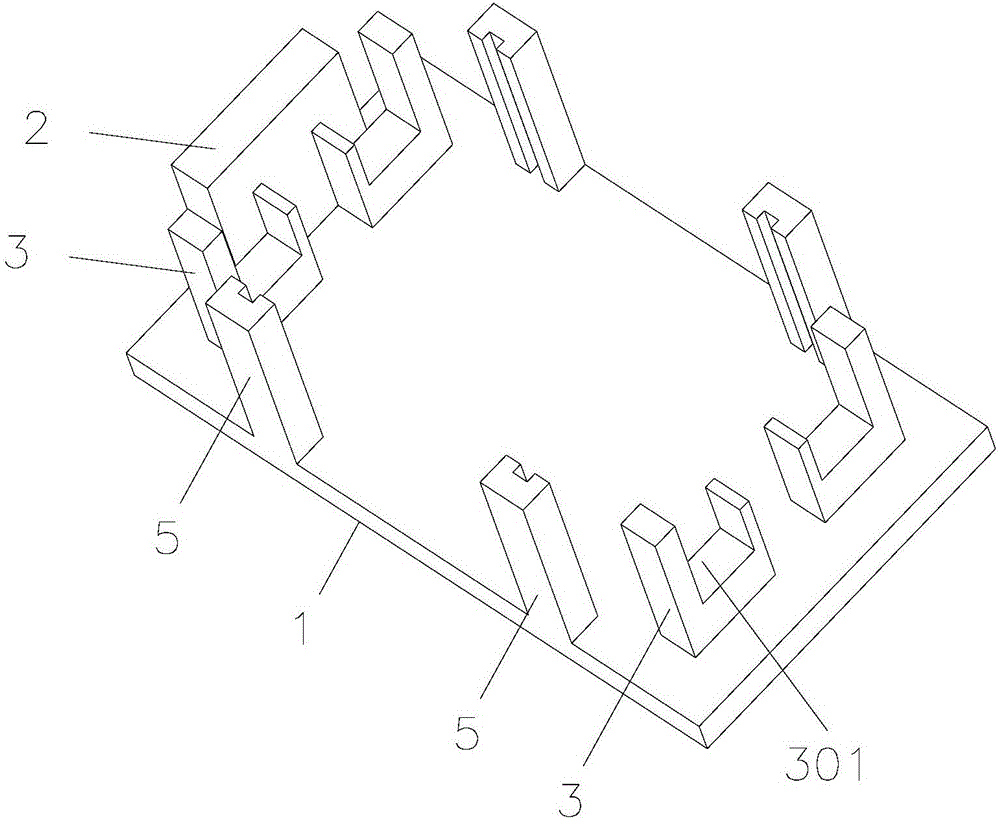

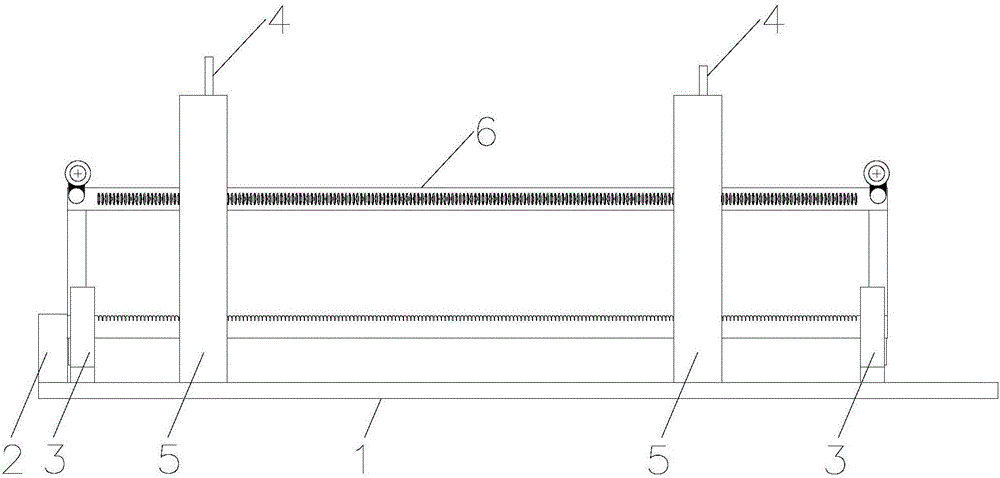

[0016] Such as figure 1 , 2 As shown in and 3, a quartz boat inspection tool, the quartz boat 6 is equidistantly distributed with a number of slots, the inspection tool includes a bottom plate 1 and two positioning seats 3 arranged on the bottom plate 1, the positioning seats 3 A reference groove 301 for positioning the quartz boat 6 is opened above the top of the base plate 1, and a detection mechanism is provided between the two positioning seats 3 on the bottom plate 1;

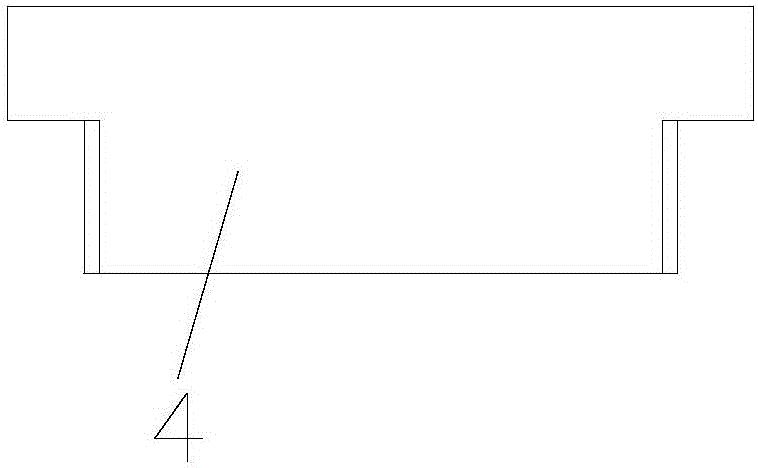

[0017] The detection mechanism includes two uprights 5 , and a verification slide 4 matching the slot is slidably arranged between the two uprights 5 .

[0018] There are two detection mechanisms, and the detection mechanisms are respectively located at two ends of the positioning seat 3 .

[0019] An auxiliary positioning plate 2 is fixed on the outer side of one of the two positioning seats 3 .

[0020] When the above-mentioned quartz boat gauge is used for boat testing, the bottom surface of the quar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap