Magnetic-induction liquid-level monitor based on CAN bus

A CAN bus, liquid level monitoring technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of manual observation, unexpected situations can not be handled in time, liquid level gauge can not work normally, etc., to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

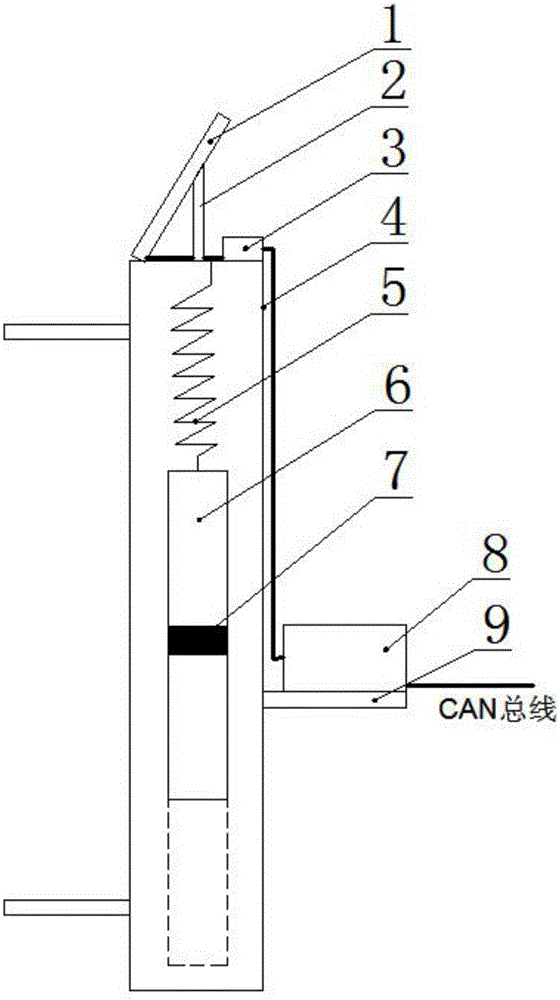

[0020] A magnetic induction liquid level monitoring device based on CAN bus, such as figure 1 As shown, it includes a cylindrical casing 4 and an electric control device 8, a spring 5 is installed on the inner wall of the top end of the cylindrical casing, a buoy 6 is installed at the bottom end of the spring, a magnetic steel 7 is installed in the buoy, and The solar panel 1 is installed on the upper surface of the cylindrical shell through the solar panel bracket 2, the solar panel is connected with the battery 3, and the output end of the battery is connected to the electric control device, and the electric control device is installed on the outer wall of the cylindrical shell. on the bracket 9 of the electronic control device.

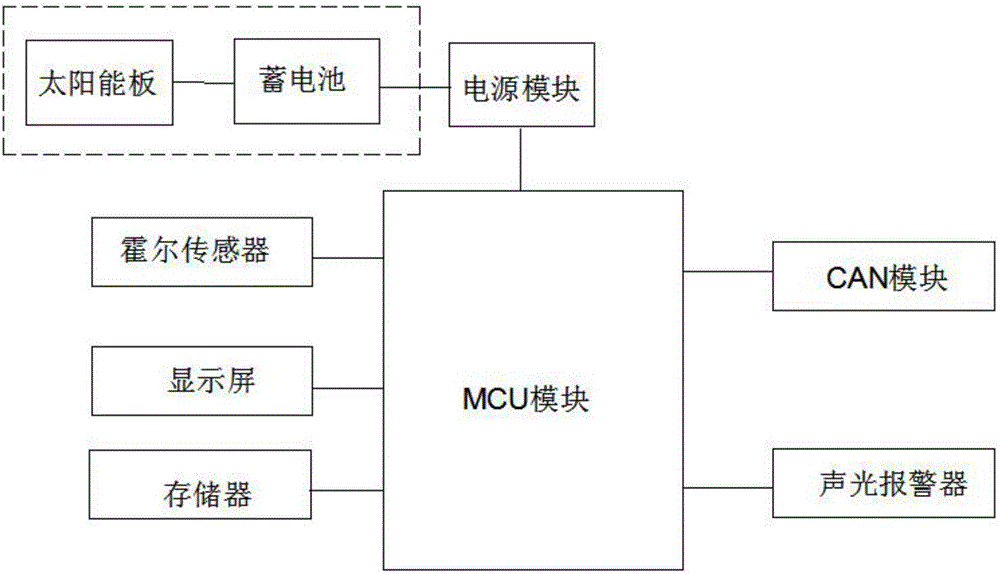

[0021] like figure 2 As shown, the electronic control device includes an MCU module, a power supply module, a Hall se

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap