Grating special controller

A controller and grid technology, applied in general control systems, program control, computer control, etc., can solve problems such as inconvenience, and achieve the effects of reducing external lines, high automation, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

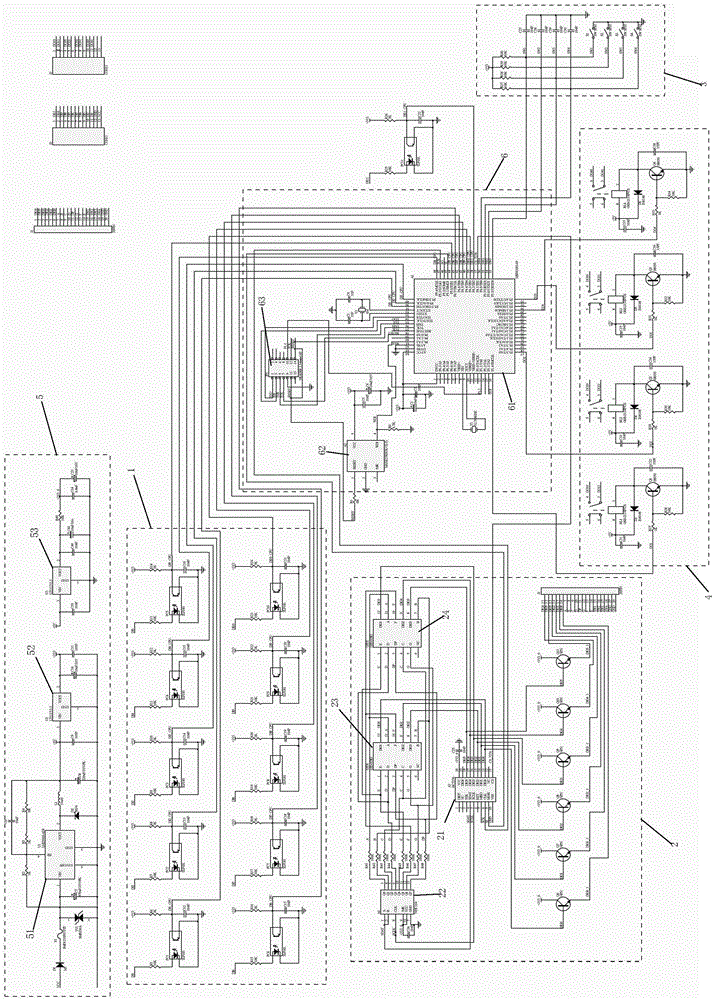

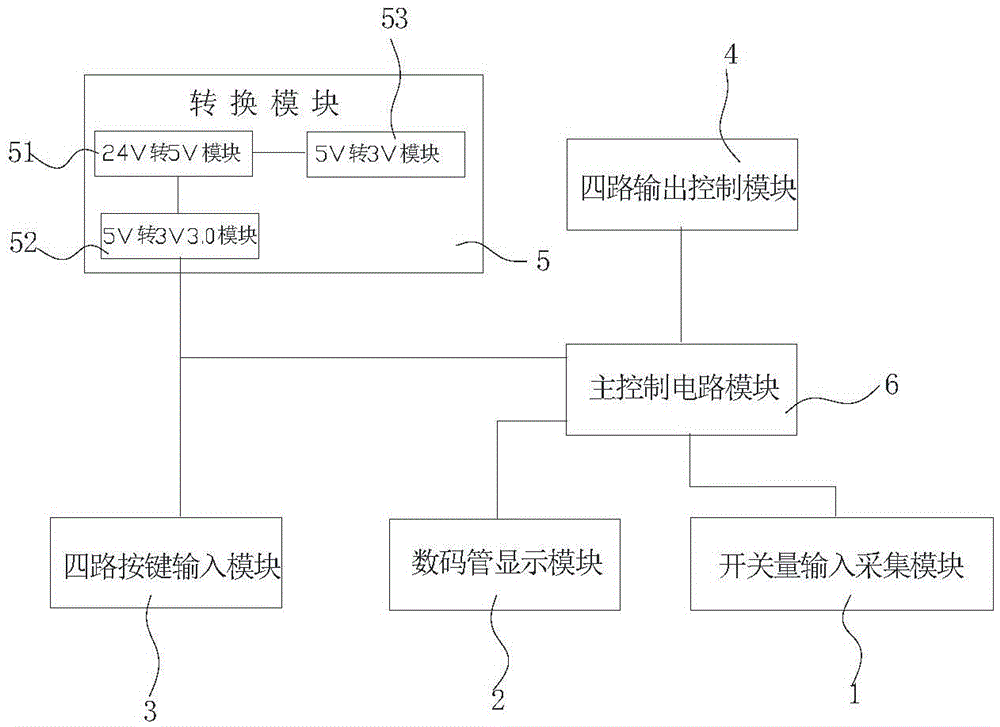

[0033] See Figure 1-3 As shown, the dedicated controller for the grid includes: a switching value input acquisition module 1, a digital tube display module 2, a four-way key input module 3, a four-way output control module 4, a conversion module 5 and a main control circuit module 6. The conversion module 5 and the switching value input acquisition module 1 are connected with the main control circuit module 6, and the main control circuit module 6 is connected with the nixie tube display module 2 and the four-way output control module 4; the four-way key input module 3 is connected with the conversion Module 5 is connected.

[0034] Specifically, the main control circuit module 6 includes: a first chip 61, a second chip 62 and a third chip 63; the first chip 61 is a mixed signal processor chip whose model is MSP430F149; the second chip 62 The model

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap