Sheet material turnover box

A turnover box and plate technology, applied in the direction of internal accessories, external accessories, etc., can solve the problems that it is difficult to ensure the appearance of the thin plate is clean and intact, the number of turnover is small, and the work efficiency is low, so as to achieve easy turnover and handling, high work efficiency and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments and drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

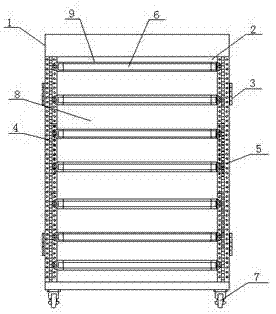

[0014] Such as figure 1 The illustrated board turnover box includes a box body 1, a containing cavity 2, a plurality of splints 9 and a universal wheel 7. The box body 1 is provided with a containing cavity 2, and the two sides of the containing cavity 2 pass through fittings 3 A fixed seat 4 is arranged symmetrically, a single fixed seat 4 is provided with a number of mounting holes 5, a plurality of splints 9 are installed in the accommodating cavity 2 through the mounting holes 5 on the fixed seat 4, and a number of cards are provided on both sides of the single splint 9 Slot 6, a plurality of card slots 6 are arranged at intervals, and a universal wheel 7

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap