PVC (Polyvinyl Chloride) composite material and preparation method thereof

A technology of composite materials and raw materials, applied in the field of PVC composite materials and its preparation, can solve the problems of impact resistance, poor thermal stability and fluidity, poor thermal stability, restrictions on hard products, etc., and achieve excellent mechanical properties and low cost Inexpensive and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

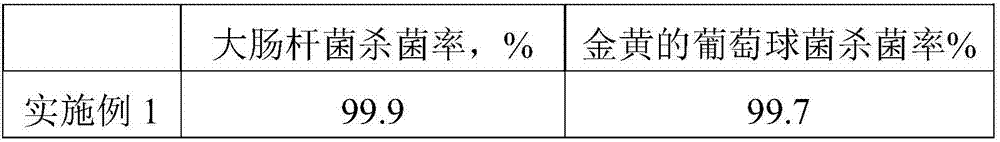

Embodiment 1

[0030] PVC composite raw materials (parts by weight): 100 parts of polyvinyl chloride resin, 10 parts of PBT resin, 3 parts of acetyl triethyl citrate, 6 parts of calcium carbonate, 1.5 parts of methyl tin mercaptide, 1.5 parts of inorganic flame retardant, Anti-aging agent 0.03 parts.

[0031] The inorganic flame retardant is obtained by stirring and uniformly mixing sodium antimonate, zinc borate and zinc molybdate in a mass ratio of 1:1:1.

[0032] The anti-aging agent is composed of 2,6-di-tert-butyl-p-(dimethylaminomethyl)phenol, 2,4-bis(1,1-dimethylethyl)-5-methylphenol, thiodipropylene Acetate didodecanyl ester is obtained by stirring and mixing uniformly at a mass ratio of 1:1:1.

[0033] Preparation of PVC composite materials:

[0034] (1) Put polyvinyl chloride resin and PBT resin into the mixer, stir for 3 hours at a speed of 600 rpm, then reduce the speed to 70 rpm, then add acetyl triethyl citrate, calcium carbonate, mercaptan Methyl tin, inorganic flame retardant

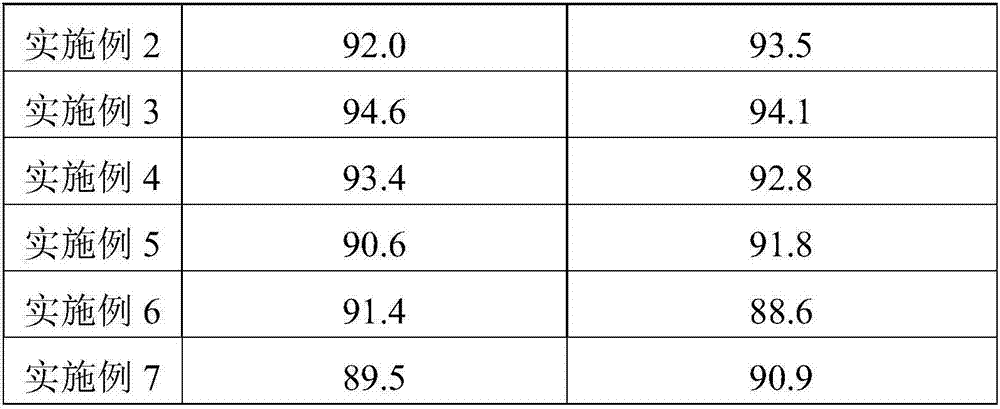

Embodiment 2

[0037] It is basically the same as Example 1, except that the inorganic flame retardant is obtained by stirring and mixing zinc borate and zinc molybdate in a mass ratio of 1:1. Obtain the PVC composite material of embodiment 2.

Embodiment 3

[0039] It is basically the same as in Example 1, except that the inorganic flame retardant is obtained by stirring and mixing uniformly sodium antimonate and zinc molybdate in a mass ratio of 1:1. Obtain the PVC composite material of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap