Degumming device for plastic film for packaging printing

A plastic film, packaging and printing technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of waste of debonding agent, damage to plastic substrates, pollution of the environment, etc., and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The present invention will be further described in detail below through specific implementations:

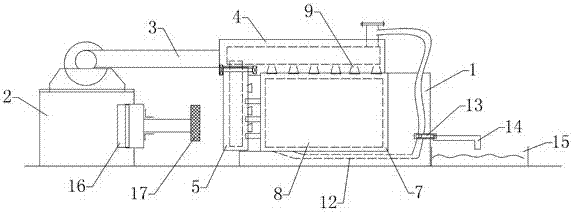

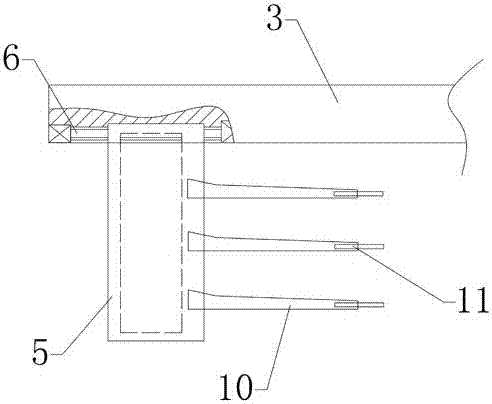

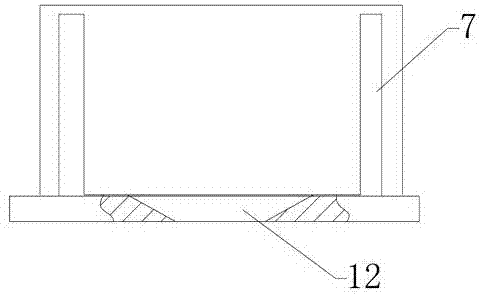

[0020] The reference signs in the drawings of the specification include: base body 1, pillar 2, lever arm 3, horizontal box body 4, vertical box body 5, chute 6, plastic plate 7, enclosed space 8, spray hole 9, latch 10 , Liquid outlet 11, liquid groove 12, three-way valve 13, branch pipe 14, container 15, cylinder 16, push plate 17.

[0021] The embodiment is basically as attached figure 1 , figure 2 Shown: a degumming device for plastic film for packaging and printing, including a base body 1 and a degumming mechanism arranged on the base body 1. A pillar 2 is provided on one side of the base body 1, and the pillar 2 is hinged with a motor to drive The degumming mechanism includes a horizontal box body 4 connected to the lever arm 3. A vertical box body 5 is slidably connected to the bottom side of the horizontal box body 4, and a chute 6 is provided at the bottom of the horiz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap